COATS 4070 Tire Changer User Manual

Page 21

Important: Always read and follow operating instructions.

• 17

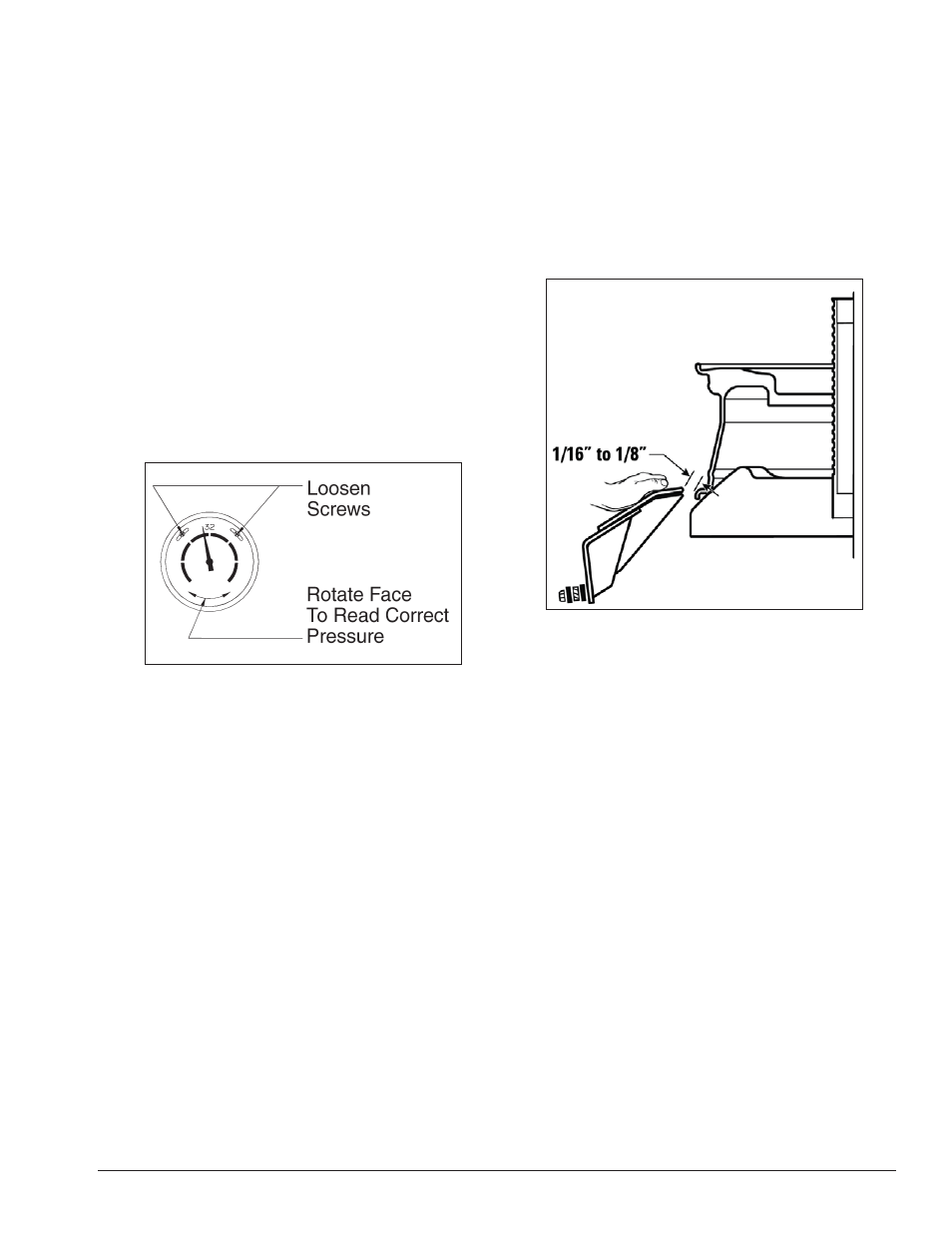

Pressure Gauge Maintenance and Calibra-

tion

Check the tire pressure gauge function on the unit

daily, and perform an accuracy check monthly. Use a

pressurized tire and a high quality stick pressure gauge.

If necessary, calibrate the dial of the machine gauge.

1.

Pressurize a large 15” tire to 30 PSI and measure

the pressure exactly with a high quality extension type

tire gauge. Connect the air chuck to the tire.

2.

Remove the gauge lens and loosen the 2 screws at

the top of the gauge and rotate the gauge face until the

indicator is pointed at the correct pressure as read with

the extension type tire gauge (figure 26).

3.

Tighten gauge face screws and replace lens.

If gauge is defective, replace it immediately (part

#8107985).

Check the function of the pressure limiter weekly as

part of your pressure gauge maintenance and calibra-

tion.

Figure 26 - Calibrating Pressure Gauge

Lower Shoe Setting

Check the lower shoe setting periodically to make

sure that it operates properly and does not contact the

wheels.

1.

Place a 15” or 16” steel wheel on the machine and

secure with the centering cone.

NOTE: Make sure the wheel is centered.

2.

Depress the foot pedal and run the lower shoe up

to 45 degrees above the radius of the lower rim flange.

Refer to figure 29.

3.

Use your left hand to push against the shoe as

forcefully as possible.

4.

Measure the gap between the closest point of

the shoe and the rim flange. The ideal measurement is

between 1/16” and 1/8” .

• If the shoe contacts the rim, add another shim.

• If the gap is smaller than 1/16” , add another shim.

• If the gap is larger than 1/8” , remove one shim.

IMPORTANT: A high setting (greater than 1/8”) is

more desirable than a low setting (less than 1/16”).

If additional shims are required, a Shim Kit (part

#8101506) is available.