Direct drive – COATS 1055 Balancer User Manual

Page 21

14. Replace the valve core and inflate the tire. Follow the tire

changer manufacturer's instructions for inflation.

Remember:

If another operator memory has been select-

ed, reselect the memory being used for the Match Mount

procedure. The balancer will return to the point in the pro-

cedure where the other memory was selected.

15. Remount the wheel on the balancer.

16. Press (2) on the control panel. 3 is now displayed in the weight

display.

17. Lower the hood and press START.

18. Wait for the wheel to stop. Raise the hood and rotate the

wheel until the valve stem is at top dead center.

19. Press 4 on the control panel.

Weights will now be displayed on the control panel. The weight in

the left display is the weight imbalance for the rim (as indicated by

the RIM light below the display). The weight in the right display is the

weight imbalance for the tire (as indicated by the TIRE light below the

display).

Use these weights to determine the suitability of the rim or tire.

High imbalance may indicate a rim that is out-of-round or misformed,

or a tire with a bubble or other problem. If the imbalance is exces-

sive, it may be prudent to replace the rim, the tire, or both. If either

is replaced do not continue this procedure. Balance the new tire and

rim and evaluate the readings for Match Mount suitability.

20. Rotate the wheel until the weight position LEDs flash. Mark

the tire at top-dead-center.

21. Remove the wheel from the balancer. Completely deflate the

tire by removing the valve core. After all the air pressure is

exhausted, follow the tire changer manufacturer's instruction for

loosening the tire beads.

A second operator can use the balancer while the Match

Mount operator continues with Steps 22, 23, and 24.

Remember:

All data for the Match Mount procedure will

be kept in the Match Mount operator's memory.

22. Lubricate both tire beads and wheel to aid in rotating the tire

and bead sealing and seating. Always use the tire manufacturer's

approved rubber lubricant.

23. Rotate the tire until the mark is aligned with the valve stem.

24. Replace the valve core and inflate the tire. Follow the tire

changer manufacturer's instructions for inflation.

Remember:

If another operator memory has been select-

ed, return the balancer to the memory being used for this

Match Mount procedure. The balancer will return to the

exact point in the procedure where the other memory was selected.

25. Remount the wheel on the balancer.

26. Use the MODE key to select the desired balance mode and

balance the wheel.

1025

1050

1055

1025

1050

1055

1025

1050

1055

Direct Drive

COATS 950/1025/1050/1055 Wheel Balancer • 15

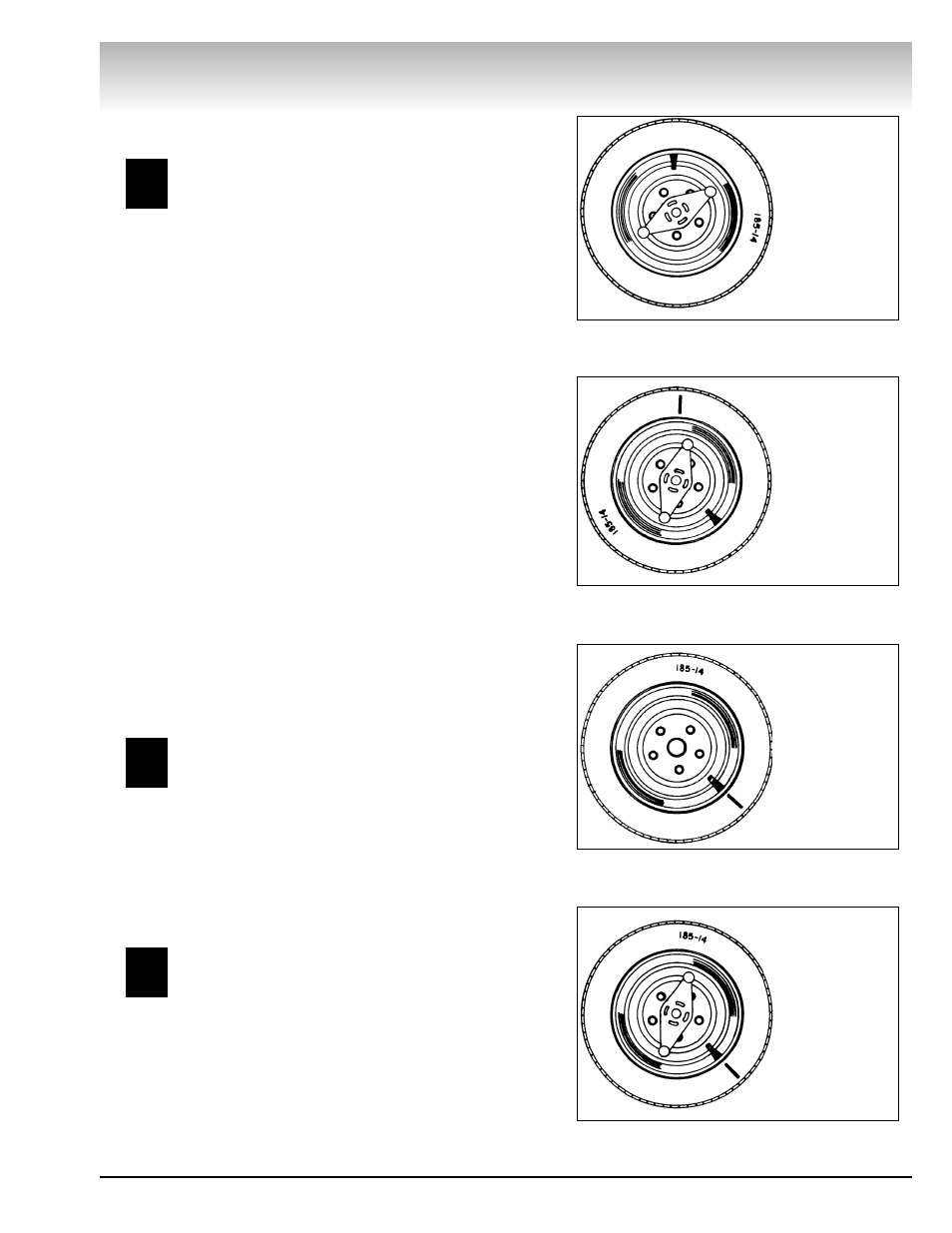

Figure 19 - Rotate the Wheel

Figure 20 - Rotate the wheel

Tire/wheel

assembly rotated

until valve stem

is at top-dead-

center

Tire/wheel

assembly rotated

until weight posi-

tion lights

flashed. Tire

marked at top-

dead-center.

Figure 21 - Rotate Tire on Wheel

Figure 22 - Match Mount Completed

Tire rotated so

mark is aligned

with valve stem.

Wheel ready for

balancing