Direct drive, Match mount – COATS 1055 Balancer User Manual

Page 20

14 • COATS 950/1025/1050/1055 Wheel Balancer

The balancer will be idle while the tire is being rotated on

the wheel. During these times, another operator without

terminating the Match Mount procedure can use the bal-

ancer. The second operator selects the other operator memory, per-

forms a balance, and then returns the balancer to the previous mem-

ory. The original operator can now continue the Match Mount proce-

dure.

As with any balancing procedure, remove any weights attached to

the wheel and inspect the tire and wheel before beginning.

Instructions

1. Mount the wheel to the balancer.

2. Select the appropriate operator memory as required. Make a

note of the memory being used in the event the memory is changed

during the Match Mount procedure.

3. Enter the A, W, and D measurements and select the mode that

will be used for the final balancing.

4. Lower the hood and press START.

5. Wait for the wheel to brake to a stop and for the displays to

show weight readings.

Does the balancer indicate that 2-ounces or more is required on

either plane of the wheel in dynamic mode? Higher weights may be

indicated when using an alloy mode to compensate for weight loca-

tion.

If so, advise supervisor or customer to continue with the Match

Mount procedure. DO NOT attach weights at this point.

If not, the Match Mount procedure is most likely not necessary, and

will not improve the balance. Continue to balance the wheel accord-

ing to the mode selected.

6. If hood start option is on, turn it off now.

7. Press the MODE key until Match Mount is selected.

8. 1 will now be displayed in the outer weight display.

9. Raise the hood and rotate the wheel until the valve stem is at

top-dead-center.

10. Press (1) on the control panel. 2 is now displayed in the weight

display.

11. Remove the wheel from the balancer. Completely deflate the

tire by removing the valve core. After all the air pressure is

exhausted, follow the tire changer manufacturer's instruction for

loosening the tire beads.

A second operator can use the balancer while the Match

Mount operator does Steps 12, 13, and 14.

Remember:

All

data for the Match Mount procedure will be kept in the

Match Mount operator's memory.

12. Lubricate both tire beads and wheel to aid in rotating the tire

and bead sealing and seating. Always use the tire manufacturer's

approved rubber lubricant.

13. Rotate the tire 180° on the wheel.

1025

1050

1055

1025

1050

1055

Direct Drive

Match Mount

Description

The Match Mount program assists the user in

determining the best possible mating of the tire

and wheel, thereby reducing the amount of addi-

tional weight required for balancing. This mating of

tire and wheel normally allows the least amount of

total runout of the assembly, resulting in better

balancing, better ride conditions, and more satis-

fied customers. Use Match Mount when:

• Excessive radial runout is noticed in the tire

and wheel assembly during balancing.

• The customer complains of ride problems.

• The balancer calls for weights in excess of 2-

ounces on either plane on passenger car tires

in the Dynamic mode.

Match Mount balancing requires loosening both

tire beads and inflation of the tire. You will need to

be trained in the operation of your Coats tire

changer and the dangers involved during bead

seating and tire inflation. Read the operators man-

ual supplied with the tire changer and consult your

supervisor.

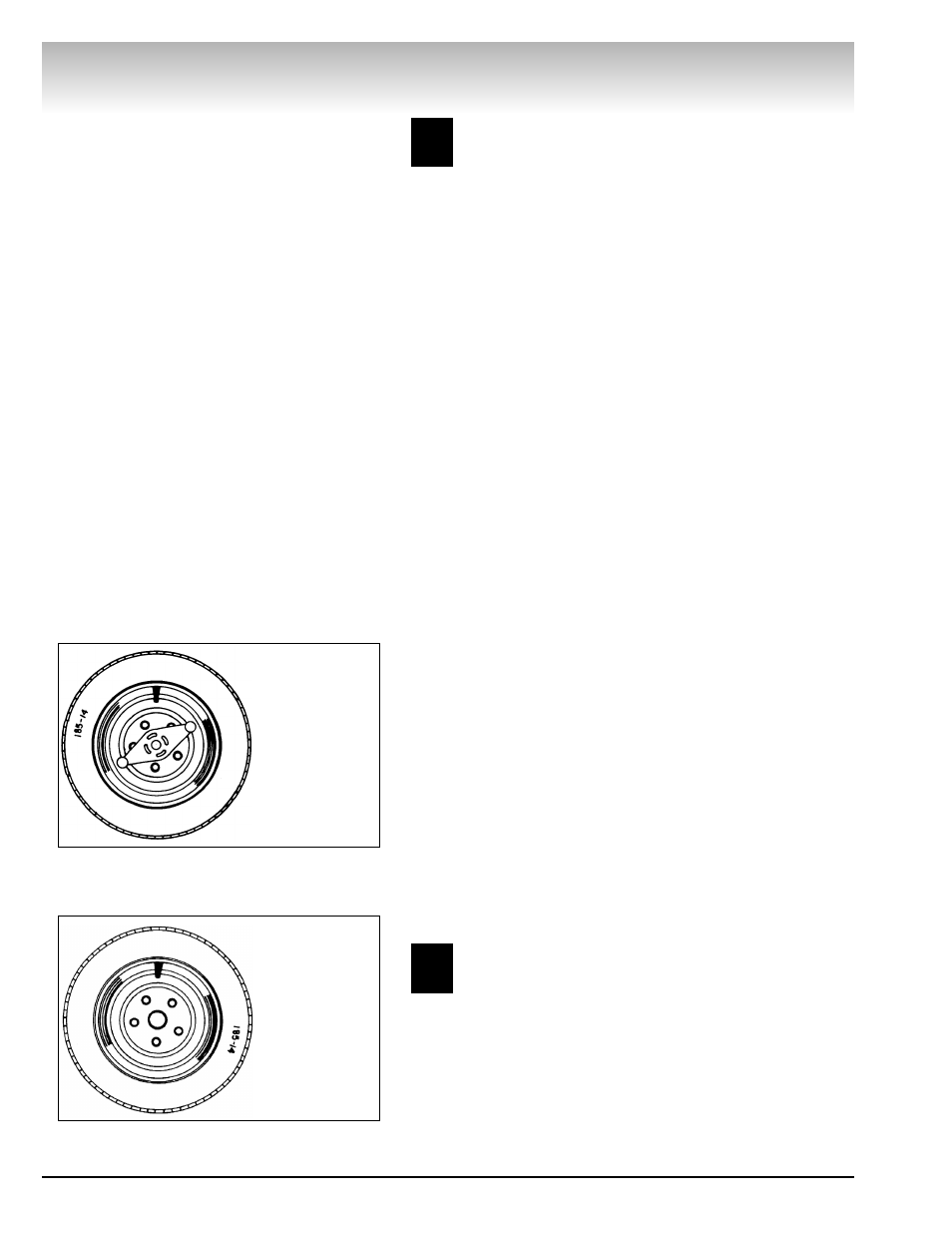

Figure 17 - Rotate the wheel

Figure 18 - Rotate Tire on Wheel

Tire/wheel

assembly rotated

until valve stem

is at top-dead-

center.

Tire rotated 180

degrees on the

wheel.