Direct drive, Balancing a wheel – COATS 850 Solid State Wheel Balancer User Manual

Page 14

8 • COATS 850SS Wheel Balancer

Direct Drive

Balancing a Wheel

1. Mount the wheel using the appropriate mounting

method.

2. Enter the A, W, and D measurements as

described in Determining Wheel Measurements sec-

tion.

Note: These measurements must be entered into

the balancer before attempting to balance a wheel. If

any of the measurements remain at zero, the balancer

will display the appropriate letter (A, W, or D) for the

missing measurement in the left display. The right dis-

play will read ERR.

3. Select a balancing mode. Press the MODE but-

ton until the LED next to the desired balancing mode

is illuminated.

4. Lower the hood. The hood interlock will not allow

the wheel to spin with the hood raised.

5. Press START. The wheel will spin and brake to a

stop. The necessary weight amounts will be dis-

played.

6. Lift the hood.

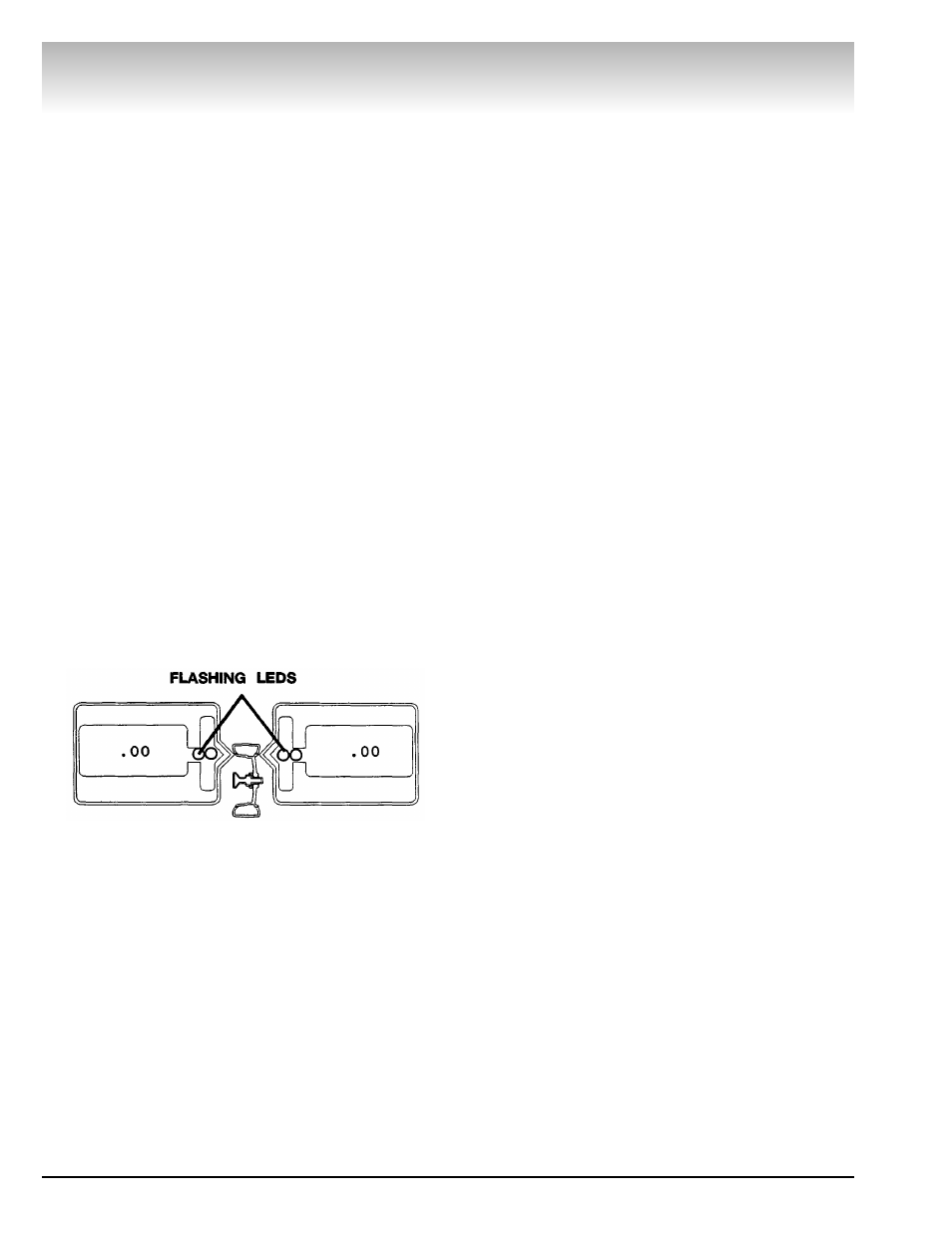

7. Rotate the wheel until the outer weight position-

ing LEDs flash. This indicates that the weight should

be attached at top-dead-center on the outer plane with

the wheel in this position.

8. Attach the appropriate weight to the outer plane.

9. Repeat steps 6 and 7 for the inner plane, if

weights are to be attached to that plane. Your selected

balancing mode will determine where the weights are

attached.

10. After weights are attached, lower the hood and

press START.

11. The wheel will brake to a stop after a full spin

cycle, and the displays should read 0.00.

If the displays indicate additional weights are

needed, consult the Balance Checking section for pos-

sible causes and corrective action.

Balance Checking

After balancing the wheel, the wheel should be re-

spun to check for accuracy. These steps, when fol-

lowed carefully, will produce a highly accurate wheel

balance.

1. Lower the hood and press START.

2. If the displays indicate additional weight is

required in the same location as the first weight, the

first weight was too small. Replace the weight with

the correct weight and re-spin.

3. If the additional weight position on the re-check is

directly opposite the first, the first weight was too

large. Replace the weight with the correct weight and

re-spin.

4. If the balancer indicates an additional weight

should be applied at an angle to the first weight, the

first weight was not applied at the correct position. To

correct, move the first weight toward the indicated

second position, or add the second weight where indi-

cated.

5. Be sure all the weights are securely attached to

the wheel.

Figure 17 - Flashing Positioning LEDs