Firing against positive overfi re pressure – Carlin 301CRD User Manual

Page 20

Model 201CRD & 301CRD 240-VAC Advanced oil burners — Instruction manual

Carlin part number MN2301A Rev. 10/21/10

– 20 –

5. Adjustment and verifi cation

Adjust burner using test instruments

1. Operate burner for 15 minutes before making fi nal adjustments using test

equipment.

2. Check for leaks in fuel piping.

Inspect fuel piping system for leaks. Repair any leaks to avoid

fi re hazard from oil leakage or combustion problems due to

air infi ltration into oil.

3. Inspect

fl

ame

• Look at fl ame through appliance combustion chamber observation port.

The fl ame should be well-defi ned and should not impinge on any appliance

surface. (If you make air changes later, inspect the fl ame again.)

Do not attempt to confi rm combustion simply by inspecting

the fl ame visually. You must use combustion test instruments.

Failure to properly verify/adjust combustion could allow unsafe

operation of the burner, resulting in severe personal injury,

death or substantial property damage.

4. Insert test probe into vent sample opening to sample fl ue products.

5. With the burner equipped with the correct oil nozzle, combustion head

setting and air band setting, the fl ue products will usually contain between

11% and 12% CO

2

(5.9% and 3.8% O

2

) and zero (Bacharach) smoke.

6. Use combustion test equipment to verify that burner is properly set up for

your installation, within the range listed in Table 3. Appliances with positive

pressure in the chamber may require a wider air opening. See appliance

instructions for details. Verify/adjust settings by testing with instruments.

a. Check smoke. It should be zero on the Bacharach scale.

b. Set the appliance fl ue damper or barometric draft regulator so the draft or

pressure in the vent complies with the appliance manufacturer’s instruc-

tions.

c. If no draft setting information is available, set the draft to –0.01 to –0.02

inches w.c. at the appliance fl ue outlet.

Heating units designed for natural draft operation are normally

set for a slightly negative pressure, usually –0.01 to –0.02

inches w.c. draft at the combustion chamber test port. Ap-

pliances designed for forced draft (positive pressure in the

chamber) must be air-tight to prevent exfi ltration of harmful

combustion products. Failure to properly set draft for the

appliance could result in severe personal injury or death.

d. Check percent of CO

2

(or O

2

). Fine tune the burner, if necessary, by slightly

adjusting the head position for more or less air.

e. Each time you change the burner air band or combustion head setting,

you will have to check and possibly adjust the draft.

f.

Recheck smoke (should be zero) and fl ue or chamber pressure/draft (adjust

if necessary and retest).

All installations should be checked after one to two weeks of

operation to ensure the appliance/burner units are operating

correctly.

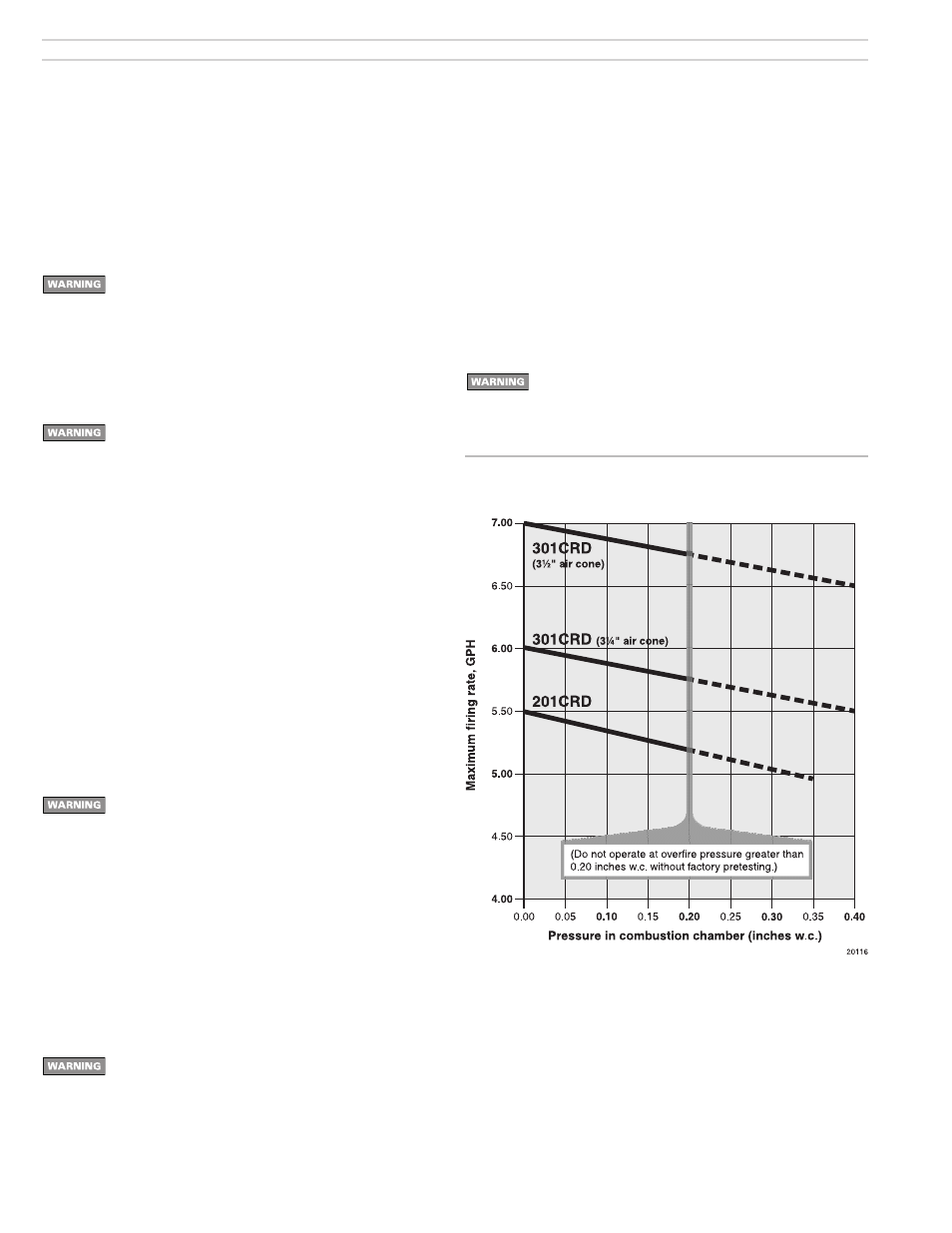

Figure 22 Maximum fi ring rate decreases as overfi re pressure

increases

Firing against positive overfi re

pressure

1. Burner rating maximum inputs are based on operation with zero to slightly

negative pressure overfi re, typically 0.01 to 0.03 inches w.c.

2. When a burner is applied to an appliance that operates with a higher pres-

sure overfi re, the maximum fi ring rate decreases because the maximum

available air fl ow from the burner blower decreases.

3. Read the graph below in Figure 22 to fi nd the maximum burner fi ring rate

at positive overfi re pressures.

Do not apply 201CRD or 301CRD burners at positive overfi re

pressure higher than shown in Figure 19 unless the applica-

tion has been factory pretested.