Auto Meter 4359 User Manual

Page 2

2

Gauge Lighting

Mounting Transmission Gear Position Sensor:

Wiring Transmission Gear Position Sensor:

Mounting the gauge:

PROGRAMMING the Gear Selection Display:

Calibration/Set up:

This gauge has no actual back lighting as it is a digital display, however when power is applied to the white wire, the digital display brightness will be

reduced by about 30%. If this white wire is connected to a dash lights rheostat, or the Auto Meter 9114 dimming module, the display will also be able

to be dimmed further. When no power is detected on the white wire (either lights turned off, or in some cases dimmed 100%, the digital display will

return to full brightness.

See Universal Gear Position Sensor section of instructions. Page 3.

This gauge is meant to be mounted into a 2-1/16” hole, the same as most other 2-1/16” Auto Meter in-dash gauges. You may want to delay final

mounting until after the gauge has been calibrated so that you have access to the brown wire for calibration. Or you may choose to final mount your

gauge, then calibrate in which case you will want to maintain access to the brown calibration wire after mounting.

During the set up procedure it will be necessary to connect the brown set up wire momentarily to ground. This can be done by connecting it to one

terminal of a normally open, momentary push button switch, and connecting the other terminal of the button to ground. Alternatively, the bare end of

the wire can be manually touched to a good ground. When doing this, make a solid connection to ground for one second, then remove the wire from

ground. The power to the gauge needs to be off in order to enter calibration mode. Connect the set up wire to ground (or push and hold calibration

button), then switch power on to the gauge, (hold ground connection on brown wire for 1 second after power up) then remove the connection to

ground. The display will flash 'P' for 5 seconds. Connect the brown set up wire momentarily to ground and release. The 'P' will now be on steady

until your next button push. Put the vehicle in Park and connect the brown set up wire momentarily to ground to capture the Park setting. Then the

gauge will flash 'R'. Connect the brown wire momentarily to ground and release. The 'R' will now be on steady until your next button push. Move gear

position selector to reverse and connect brown set up wire momentarily to ground to capture the reverse settings. Repeat for all gear positions. If a

letter or number is to be skipped, simply do not connect the wire to ground while the character is flashing. After 5 seconds it will move on to the next

position.

The PRNDL gauge must be set up, or calibrated before use. To do this, the sender unit must be installed on the transmission linkage, the

transmission linkage must be properly adjusted, and the gauge must be wired up. Before getting started, determine what letters and numbers

you want to use. The list of available options can be found below. This gauge comes with the following letters and numbers that can be used in

programming your gauge:

P, R, N, D, L, od, O, 5, 4, 3, 2, 1.

Any of the above can be easily skipped by letting the number or letter time-out while flashing, while in calibration mode. Some common examples of

what you might use, are listed below, however you can program it to read any way you like.

A typical 4-speed over-drive automatic may use: P, R, N, od, D, 2, 1.

Or may use : P, R, N, D, 3, 2, 1. another option would be P, R, N, O, 3, 2, 1. In this case, the large-case “O” would stand for over drive.

A typical 3-speed automatic may use P, R, N, D, 2, 1, or P, R, N, 3, 2, 1.

A Powerglide 2-speed might use P, R, N, D, L, or P, R, N, D, 1, or P, R, N, 2, 1.

These are just a few examples, and you can program however you choose. It also does not matter if your vehicle is equipped with a reverse valve

body. You simply have to be in the correct gear when you capture the reading that you are programming.

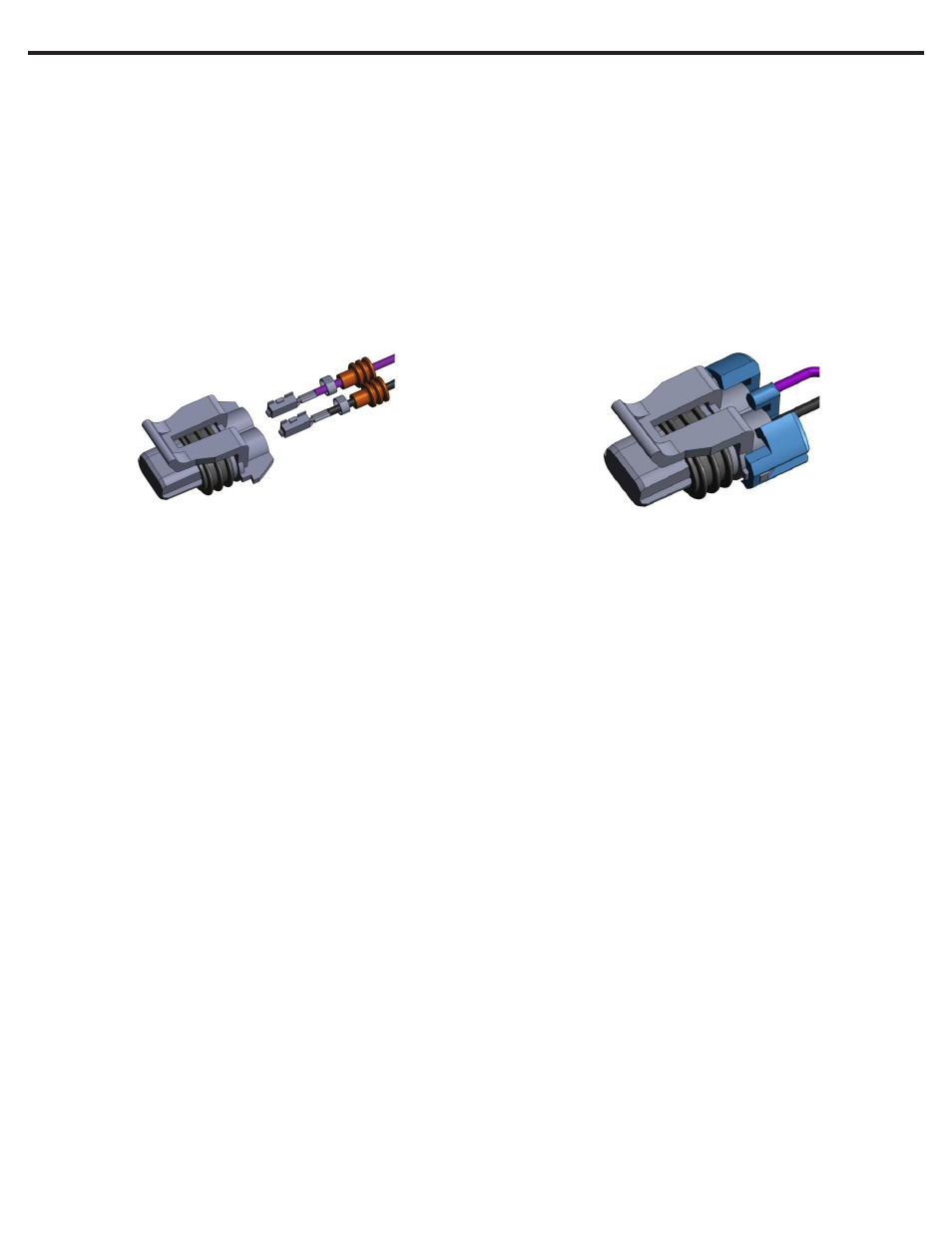

After the sending unit has been installed and the black and purple wire have been fed through the firewall, attach the purple and black wire to the

connector housing and add the lock.

1. Insert the terminals into the connector housing. It does

2. Add blue lock.

not matter on what side the black and purple wire goes.

The sensor is not polarity sensitive.

3. Plug into the mating connector on the sensor.