Auto Meter 7955 User Manual

Power-up, Installation, Full sweep electric temperature gauges

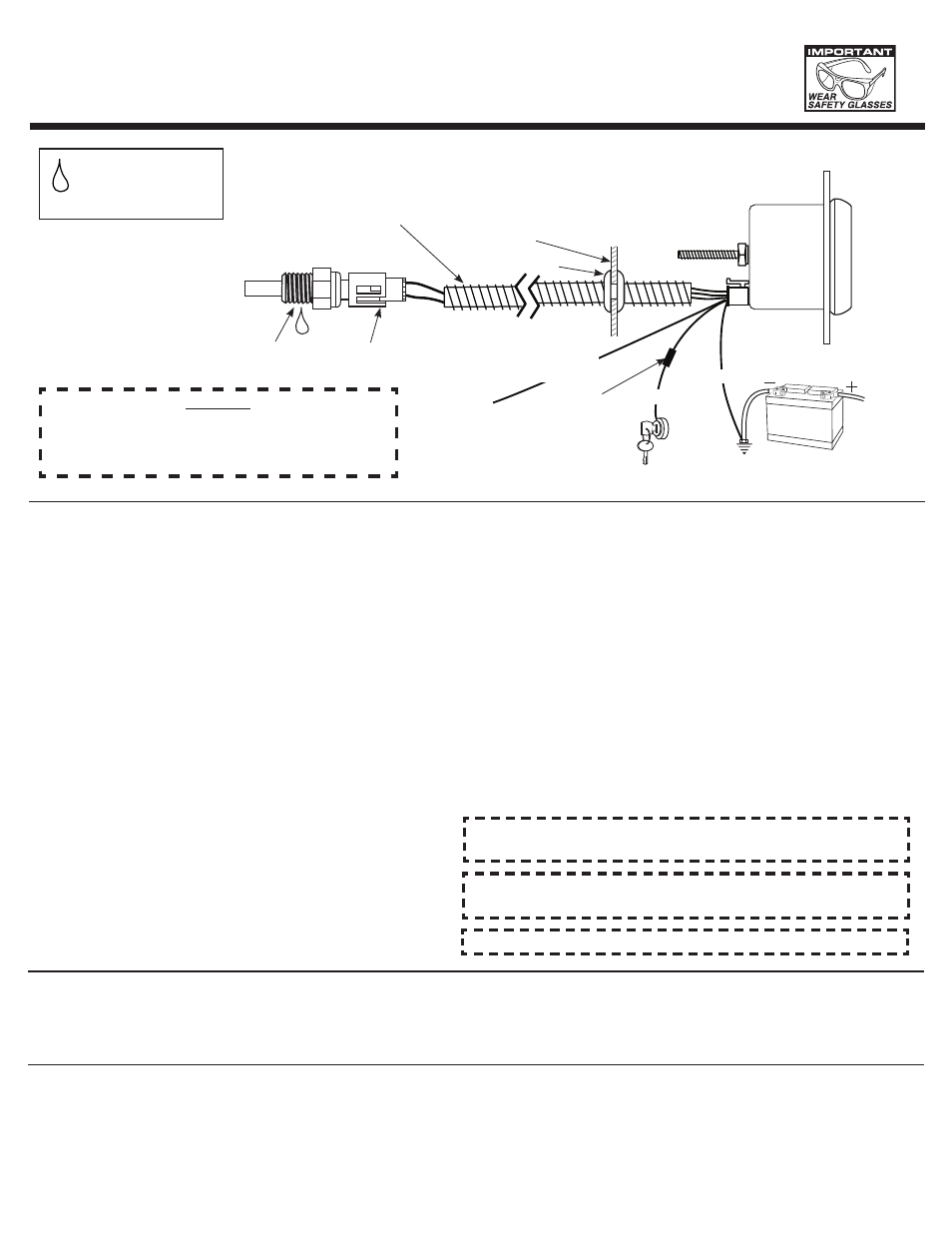

12V BatterY

SENDER

1/8” NPT

GOOD ENGINE

GROUND

GROMMET

+ 12v CONNECTION

RED

BLACK

Power-Up

The pointer will move backward to the stop pin and then display actual temperature. This procedure is an auto-calibration function and is

performed on every power-up. While this test is being performed, the gauge may make a clicking sound. This is normal.

Use teflon sealing

taPe or sealing

comPoUnd on

PiPe threads

caUtion!

As a safety precaution, the +12V terminal of this product

should be fused before connecting to the +12V ignition

switch. We recommend using a 1 Amp, 3AG fast-acting type

cartridge fuse (Littlefuse® # 312 001 or an equivalent).

installation

WIRING

HARNESS

FUSE

(SEE CAUTION

BELOW)

FIREWALL

+12v

DASH

note: When the ignition is off the pointer may not always rest at zero.

note: Some late model vehicles use electronic sensors in their

pressure and temperature senders for engine control

functions. Before removing the original sender, we

recommend that you contact your automotive dealer to be

sure no critical functions will be disrupted.

1. Check that you have all parts required for installation,

and the engine is cool.

2. Disconnect the negative (-) battery cable.

3. Gauge mounts in a 2-

1

/

16

” hole for 2-

1

/

16

” gauge and 2-

5

/

8

” hole

for 2-

5

/

8

” gauge. Use supplied brackets and nuts to secure

gauge to dash.

4. Drill 1” diameter hole where wires pass through sheet metal

(such as firewall and install rubber grommet provided.

(Grommet will require slit.)

5 Connect the white wire to dash lighting or switchable +12v light

source, the red wire to switched +12V source and the black

wire to ground (see diagram for details)

6. Install temperature sender.

A. Water Temp: Install temperature sender.

Note: Included sender is

1

/

8

” NPT. For

3

/

8

” NPT or

1

/

2

”

NPT ports, use included adapter.

B. Trans. Temp: Hole may have to be drilled, and adapter

nut welded or brazed in pan. Be sure there is adequate

internal clearance for nut and sender.

7. Cut end of included dielectric grease packet, and squeeze grease

into connector of temperature sender prior to connecting harness

(Important: This will protect connection from dirt and moisture.)

8. Connect red wire to switched +12V source and the black wire to

ground. (see diagram for details)

9. Reconnect negative (-) battery cable.

note: Test all fittings and connections for leaks. If any leaks are

detected, determine the cause of the leak and repair.

Do not operate vehicle if any leaks are detected.

note: Do not remove factory temp sender to install temp sender. If no

location found, a hose adapter can be used.

OPTIONAL SLIT TUBING

RECOMMENDED

(AVAILABLE AT MOST

HARDWARE STORES)

caution: LUBRIPLATE

®

DS-ES is a non-hazardous substance.

However, it is recommended to wash hands thoroughly after use.

FOR INTERNAL LED

LIT INSTRUMENTS

WHITE

installation instrUctions

fUll sweeP electric temPeratUre gaUges

2650-1437-00

with warning light and PeaK recall