Auto Meter 5747 User Manual

Short sweep electric gauges, Mounting, Wiring

White Wire:

Connect to +12 Volt Lighting

INSTALLATION INSTRUCTIONS

SHORT SWEEP ELECTRIC GAUGES

2650-1079-00 Rev. C

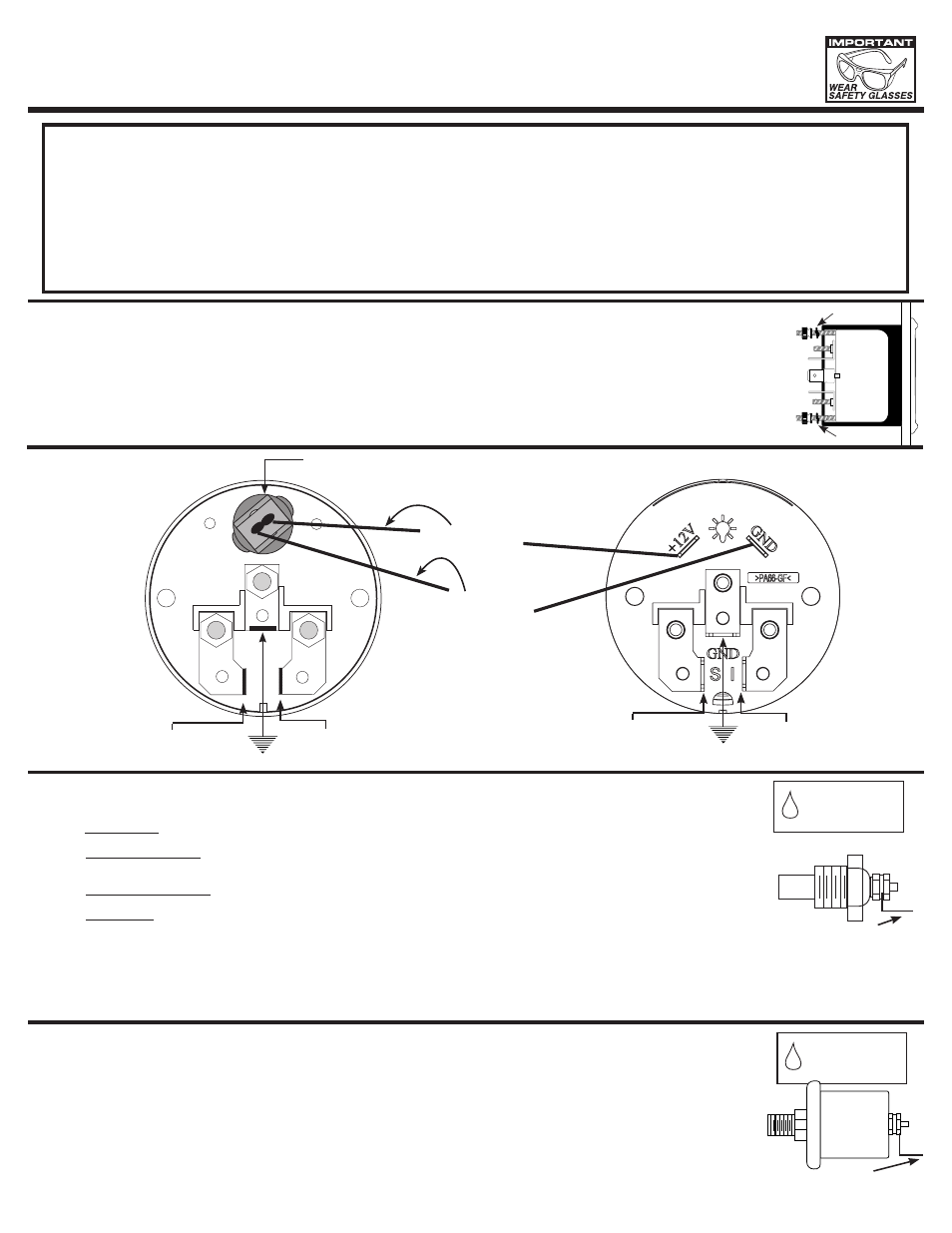

Mounting

Replace light bulb with the same

number bulb as the one removed.

These gauges can be mounted in-dash or in Auto Meter mounting solutions (panels, cups, pods, etc.). 2

1

⁄

16

" diameter gauges mount in

2

1

⁄

16

" hole, 2

5

⁄

8

" diameter gauges mount in 2

5

⁄

8

" hole. Fasten with brackets supplied as shown. (Hookup wire is required.) To assure

proper functioning of this instrument, please read instructions thoroughly before installing.

Lockwasher

Lockwasher

CAUTION FOR ALL GAUGE INSTALLATION (AMMETERS EXCLUDED)

As a safety precaution, the +12V wire attached to the positive

I (+) terminal of the gauge should be fused before connecting to the positive (+)

output side of the ignition switch. We recommend using a 3 Amp, automotive type fuse inline between the power supply source and the

I (+)

terminal on the gauge.

NOTE: Some late model vehicles use electronic sensors in their pressure and temperature senders for engine control functions. Before removing the

original sender, we recommend that you contact your automotive dealer to be sure no critical functions will be disrupted. With pressure gauges it

is beneficial to add a T-fitting to install your new gauge and to keep the warning light operational. This allows you to monitor the pressure and still

have a warning light to indicate emergency conditions.

NOTE:: Disconnect negative (-) battery cable before installation.

CAUTION: Do not touch ignition wire to the sender (S) terminal on back of gauge or the sender may be damaged.

GND

S I

Twist-In Light

GAUGE

(back view)

Ground

FRONT MOUNTING

(BOTTOM VIEW)

To Sender

(not used on Voltmeter)

To Sender

(not used on Voltmeter)

GAUGE

(back view)

Wiring

Ground

Note: Sender grounds

through threads

Black Wire:

Connect to Good Ground

or dimming circuits on some

import vehicles

GND

S I

Pressure Gauges

Temperature Gauges

TEMPERATURE SENDER

USE TEFLON SEALING

COMPOUND ON PIPE

THREADS

1. Install temperature sender.

A. Water Temp: Install temperature sender (included). Purchase of additional fittings such as metric or hose adapters may be

required.

B. Oil & Trans. Temp: Hole may have to be drilled and adapter nut (included) welded or brazed in pan. Be sure there is

adequate internal clearance for nut and sender. Sender should automatically be grounded when installed. If not, proper

ground connections should be made. May use #2260 weld on bung on steel pans (not included).

C. Cylinder Head Temp: Head must be drilled and tapped for

1

⁄

8

" NPT hole. Sender should be grounded automatically when

installed. If not, proper ground connections should be made. Be sure not to drill all the way through.

D. Diff. Temp: Install temperature sender in

1

⁄

8

" NPT sender port on cover if available. If cover does not have a port,

remove cover and drill and tap a

1

⁄

8

" NPT hole or, drill and weld, or braze, adapter nut (included) in cover. Proper ground

connections should be made by running ground wire from bolt in cover to chassis, being sure to leave enough slack in wire

for suspension travel.

2. Route 18-gage wire through firewall. If a new hole is drilled in the firewall a grommet is recommended. Connect one end to

terminal post on temperature sender, and opposite end to sender (S) terminal on back of gauge.

3. Route 18-gage wire from center terminal GND (-) on back of gauge to good ground near sender.

4. Connect wire from ignition switch to ignition (

I

) terminal on back of gauge.

5. Reconnect negative (-) battery cable.

USE TEFLON SEALING

COMPOUND ON PIPE

THREADS

1. Install sender into pressure port of appropriate type.

If unit is to be installed on a high vibration application such as a full

race engine or engine capable of high RPM, it is strongly recommended that the sender be remote mounted to either

the fenderwell or firewall, to insulate from vibration. Failure to remote-locate pressure senders on such an application

could result in gauge failure and potential damage to vehicle and/or operator injury. Braided stainless steel lines are sold

separately by Auto Meter, and can be used to accomplish this. Sender features

1

⁄

8

"

NPT male fitting and comes with

1

⁄

4

"

NPT

adapter. Sender should automatically be grounded when installed. If not, or if remote relocation of sender is required, a ground

connection to sender “body” may need to be made.

2. Route 18-gage wire through firewall. If a new hole is drilled in the firewall a grommet is recommended. Connect one end to

terminal post on pressure sender, and opposite end to sender (S) terminal on back of gauge.

3. Connect wire from center terminal GND (-) on back of gauge to good engine ground near sender.

4. Connect wire from ignition switch to ignition (

I ) terminal on back of gauge.

5. Reconnect negative (-) battery cable.

To S-Terminal on gauge

Note: Sender grounds

through threads

If this product is to be installed on a vehicle requiring metric fittings, please contact you local Auto Meter dealer

to purchase metric adapters. A complete listing of the fittings available can be found in our catalog or online at

http://www.autometer.com

Metric Adapters

Internal LED Lighted Models

To 12V Terminal on

Ignition Switch or other

switched 12V source.

To 12V Terminal on

Ignition Switch or other

switched 12V source.

PRESSURE

SENDER

To S-Terminal on gauge

- 5815 2092 2093 880430 880260 880243 880241 880431 880429 880428 880242 880240 880016 880030 3837 3849 3827 3815 3892 3848 3816 3813 8049 8037 8016 8014 8092 8048 8027 8015 3613-00406 3649-00406 3627-00406 3692-00406 5837-00407 5891-00407 5827-00407 5837-00406 5891-00406 5827-00406 5937-M 5937 5949 5948 5927 5915 5992 5948-M 5927-M 5916 5913 7115 7148 7127 7116 7113 7149 7137 4837 4791 4737 4891 4757 4848 4727 4815 4814 4716 4748 4827 4816 4715 4714 6192 6127 6148 6115 7914 6137 6113 7915 7916 7927 7937 6148-M 6137-M 7991 6127-M 1294