Auto Meter 7570 User Manual

Installation, Mounting sensor, Wideband air/fuel ratio monitor - analog

NOTE: OK for use with Nitrous Oxide.

INSTALLATION INSTRUCTIONS

2

1

/

16

"

WIDEBAND AIR/fUEL RATIO

MONITOR - ANALOG

®

2650-1469-00

Installation

1. Disconnect the negative (-) battery cable.

2. Gauge can be mounted in a 2

1

⁄

16

”. hole with brackets

supplied. Gauge can also be mounted in Auto Meter

Mounting Cup, or in Auto Meter Gauge Works Pods.

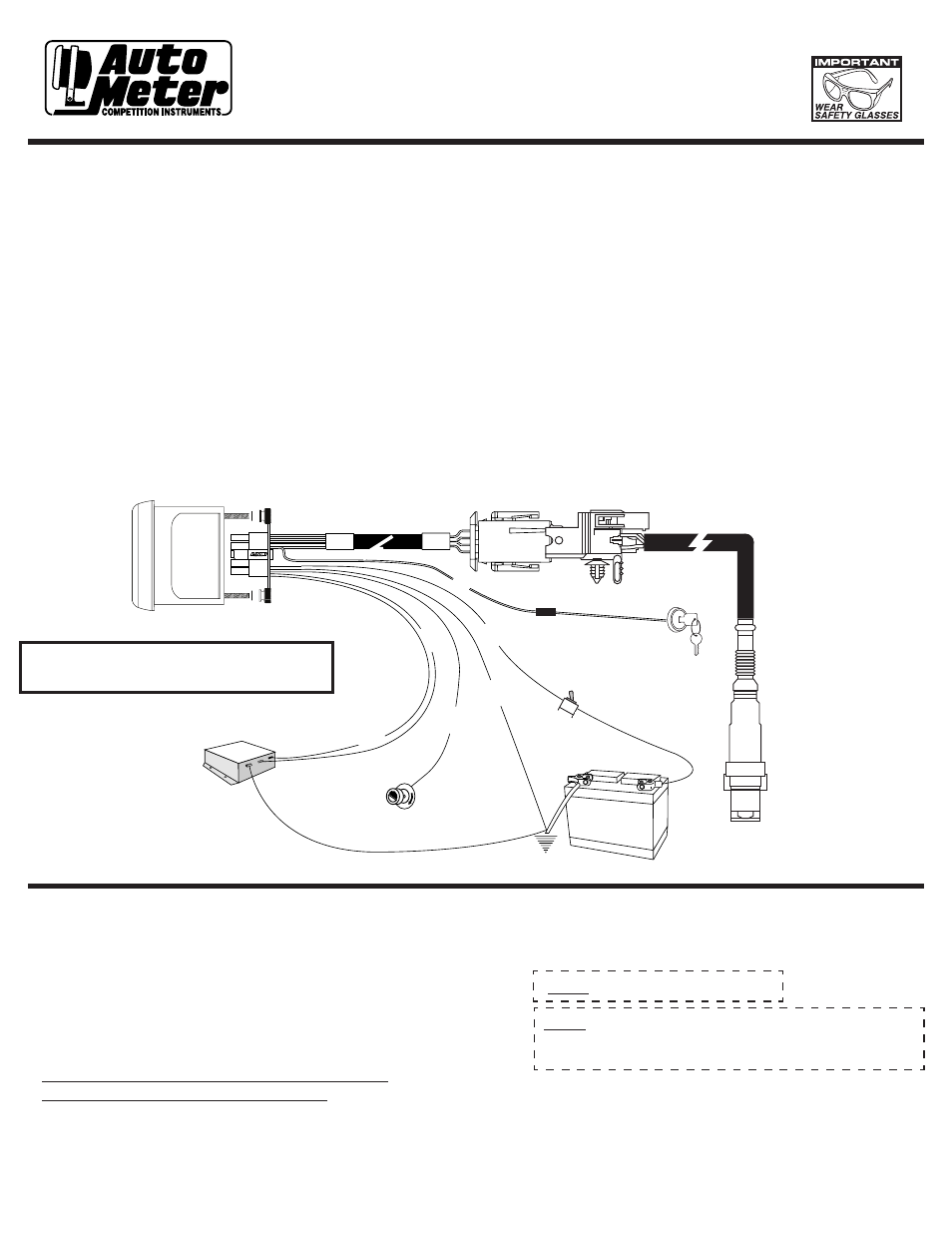

3. Wire gauge as shown.

Red Wire (Power):

Connect to a fused and switched 12V positive source

that is turned on and off with the ignition switch. Place a 3

amp automotive fuse (available commercially) in line with

this connection to protect your gauge. It is recommended

that vehicles without alternators connect this wire to a

separate switch or direct to the vehicle’s master cutoff

switch. (See Heater Control Mode Section).

When power is applied to the gauge the pointer will move

counter clockwise to the stop pin, where it will remain

until voltage exceeds 12.5 v or voltage is applied to the

brown wire.

Once the gauge sees 12.5 volts, it will

begin heating the sensor and the pointer will move

back and forth between 8.0 and 9.0 on the dial. When

The heated oxygen sensor comes with a stainless steel weld-in bung,

plug, and wiring harness. The oxygen sensor should be installed

as close to the cylinder head as is reasonably possible so that the

sensor reaches operating temperature quickly. If long tube headers

are used, the oxygen sensor should be installed in the collector. If

cast iron manifold(s) or shorty headers are used, install the sensor in

the pipe just below the manifold. In multi-bank applications mounting

in the left or right side is acceptable. Turbocharged applications

should have sensor installed 4-5" after turbo on the down pipe.

The Air/Fuel Ratio Monitor is intended for

use with

unleaded gasoline only.

NOTE: Stoichiometric Air / Fuel Ratio is the chemically correct

ratio where theoretically all of the oxygen and all of the

fuel are consumed. The mixture is neither rich or lean.

Mounting Sensor

Auto Meter recommends welding supplied

stainless steel bung with a TIG welder.

WARNING

Sender Will Get Very Hot During Operation.

1. The exhaust pipe in front of the sensor should not contain any pockets, projections, protrusions, edges, flex-tubes etc. to avoid

accumulation of condensation. A downwards slope of the pipe is recommended. If the exhaust pipe is parallel to the ground, the

sensor must be installed in the top half of the pipe to avoid damage to due to condensation

2. Tightening torque: 30-44 ft Ibs.

3. Avoid excessive heating of the sensor cable. Route sensor cable away from exhaust pipe.

4. The maximum temperature of the sensor on the outside of the exhaust fitting should not exceed 900

o

F.

the sensor is heated to the proper operating temperature the gauge will

begin reading air/fuel ratio in real-time.

Black Wire (Ground):

Connect to good engine ground.

White Wire (Lighting):

Connect to dash lighting dimmer control.

Brown Wire (Heater Override for applications that provide less than

12.5 volts with engine running):

Connect to a normally open switch. Connect the

other switch terminal to battery positive (+).

Blue Wire (Optional Data Logger Signal Output):

Connect to signal input(+) or Engine Management System

or Data Acquisition unit.

Black Wire (Optional Data Logger Signal Ground):

Connect to signal input(-) on Engine Management system

or Data Acquisition Unit.

12V Ignition

Switch

Good

Engine Ground

12V Dash Lighting

or Auto Meter 9114

Dimmer Module

Fuse

Normally

Open Switch

(Optional)

Red

Brown

Blue

Black

Black

White

_

+

Data Logger

Gauge

Sensor