Oon n- -t th he e- -v ve eh hiic clle e, Caution – AMMCO 800 On-The-Vehicle Brake Lathe User Manual

Page 26

20 • AMMCO 800 On-The-Vehicle Brake Lathe

O

On

n-

-T

Th

he

e-

-V

Ve

eh

hiic

clle

e

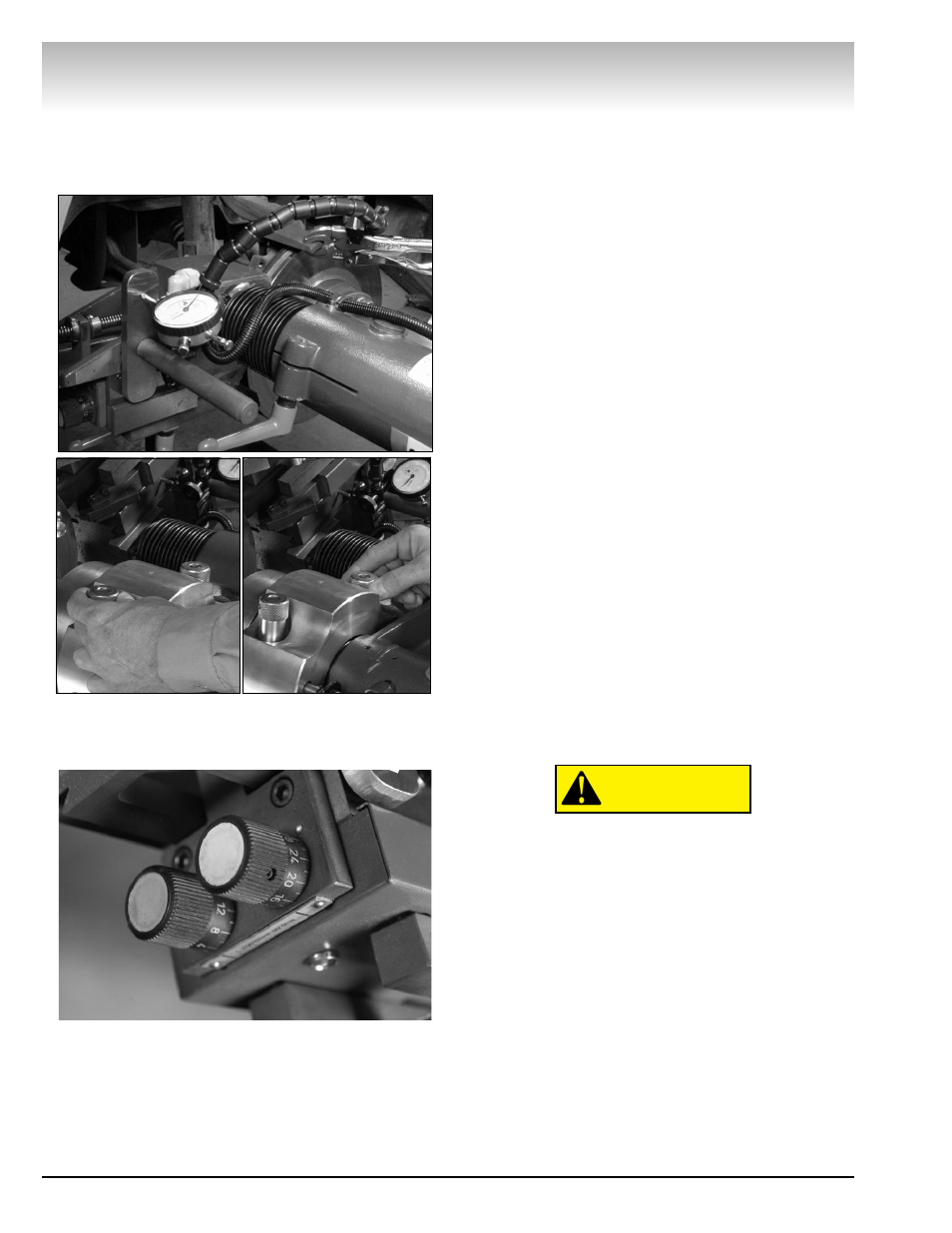

14.3 Attach runout indicator to the vehicle wheel

suspension, turn on the 800 brake lathe, and make the

runout adjustment required in the same manner as

previously described in section 10.3 on page 15.

14.4 When making tool holder adjustments in the

inverted position use the insert adjustment knob ref-

erence dot as shown in the photo below.

14.5 Inspect the rotor after machining to verify that

the runout and thickness meet manufacturer’s specifi-

cations.

14.6 Remove the chatter band and hub adapter.

P

Pr

re

ev

ve

en

nt

tiiv

ve

e M

Ma

aiin

nt

te

en

na

an

nc

ce

e

Oiling

15.0 The lathe is shipped from the factory with the

correct amount and type of oil. Refill as necessary

with EP-80-90 gear oil and check the oil level periodi-

cally.

Drain the oil annually and refill to the proper level

with clean EP-80-90 gear oil. To drain the oil, remove

the socket head drain plug located on the top of the

lathe above the spindle.

15.1 General Lubrication — Oil the ways of the

head assembly periodically. Lub points located on

either side of head assembly.

15.2 Lubricate feed actuator plunger with light oil

(3-4 pumps using oiler) periodically. Lubrication point

located at center of feed drive assembly cover.

Note: Stand cylinder requires no lubrication.

Cleaning

15.3 Keep the lathe as clean as possible for trou-

ble free operation as well as safety and longer lathe

life. Use a brush to sweep metal chips and dust off the

lathe. DO NOT USE COMPRESSED AIR TO BLOW

THE LATHE CLEAN. Chips and dust may be driven

between machined parts and into bearings causing

undue wear.

15.4 Although stand does not require any specific

service, it is a good idea to periodically wipe the

counter balancer cylinder shaft clean of debris and

apply a light coat of oil.

Care of Hub Adapters

Although the hub adapters are made of top

grade steel and are turned, and hardened,

to close tolerances, care should be taken in

their use, handling, and storage.

15.5 Remove the lathe and hub adapter after

machining a rotor and wipe them clean.

15.6 Regularly inspect the faces of the hub

adapters for nicks and scratches, correct any flaw with

a fine stone. If the damage cannot be corrected,

replace the hub adapter. Handle the hub adapters with

care and store them in the hub adapter holder or on

individual hooks. DO NOT throw them into a box. The

hub adapters are designed for mounting rotors only,

MISUSE WILL YIELD POOR RESULTS.

CAUTION