Oon n- -t th he e- -v ve eh hiic clle e – AMMCO 800 On-The-Vehicle Brake Lathe User Manual

Page 25

AMMCO 800 On-The-Vehicle Brake Lathe • 19

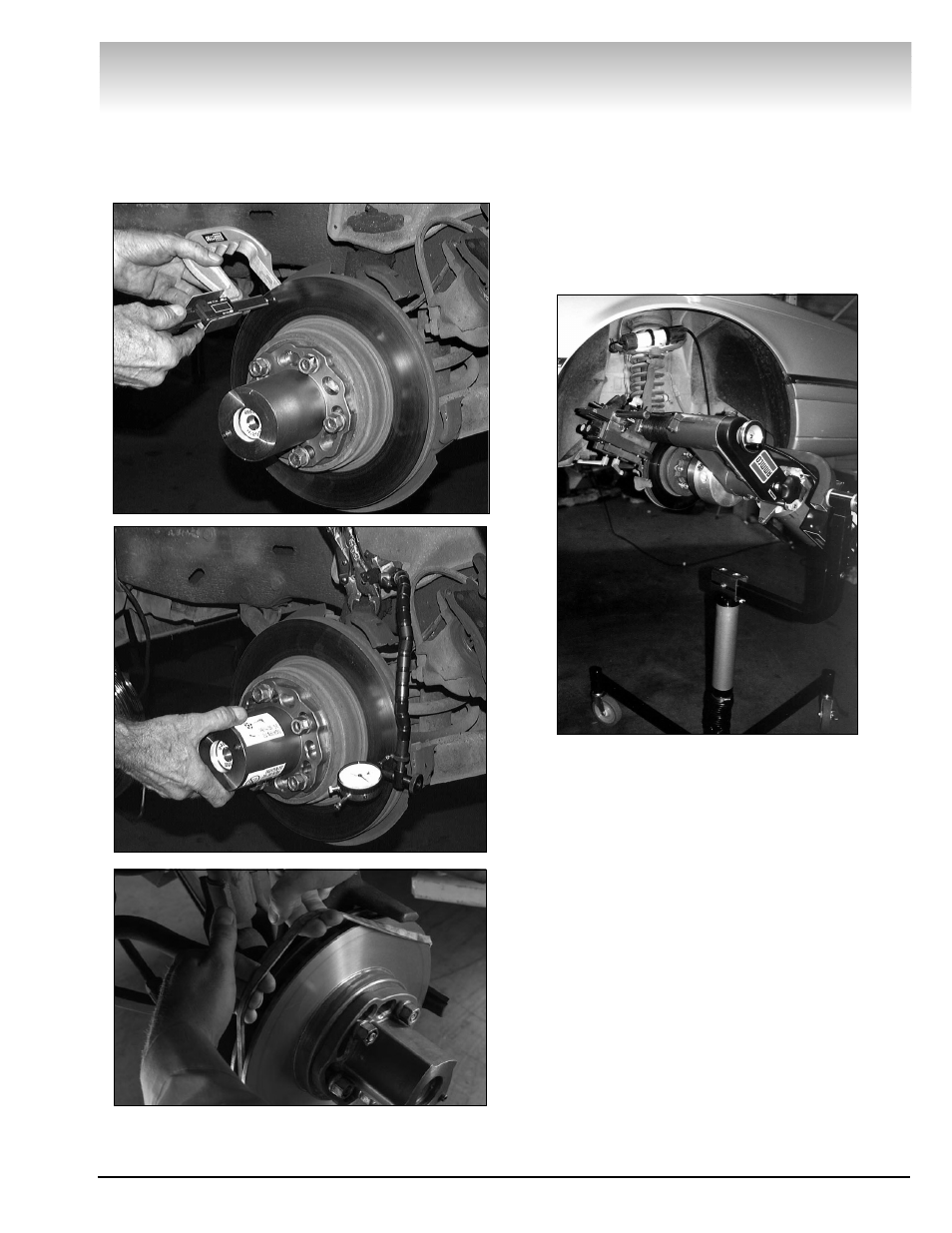

13.5 Inspect the rotor after machining to verify that

the rotor runout and thickness meet manufacturer’s

specifications.

13.6 Remove the chatter band and hub adapter.

Setup for Opposite Side Vehicle Rotor

Resurfacing

14.0 To cut the brake rotor on the opposite side of

most vehicles, the 800 brake lathe most be rotated to

its inverted position. To invert the lathe loosen the

pivot-locking lever on the portable stand system.

Adjust to an angular position, as done for the first

rotor, to assure lathe clearance during the refinishing

process, then tighten the pivot-locking lever.

14.1 Rotate the spindle manually, using the motor

handwheel, to position the adjustment knobs (red and

blue) to the up position, and insert the lock pin (yellow)

into the runout adjustment head.

14.2 After the 800 brake lathe has been attached

to the vehicle, it is not necessary to center the cutting

head assembly as that was accomplished on the first

rotor.

O

On

n-

-T

Th

he

e-

-V

Ve

eh

hiic

clle

e