Oon n- -t th he e- -v ve eh hiic clle e – AMMCO 800 On-The-Vehicle Brake Lathe User Manual

Page 18

12 • AMMCO 800 On-The-Vehicle Brake Lathe

O

On

n-

-T

Th

he

e-

-V

Ve

eh

hiic

clle

e

Brake Rotor Inspection

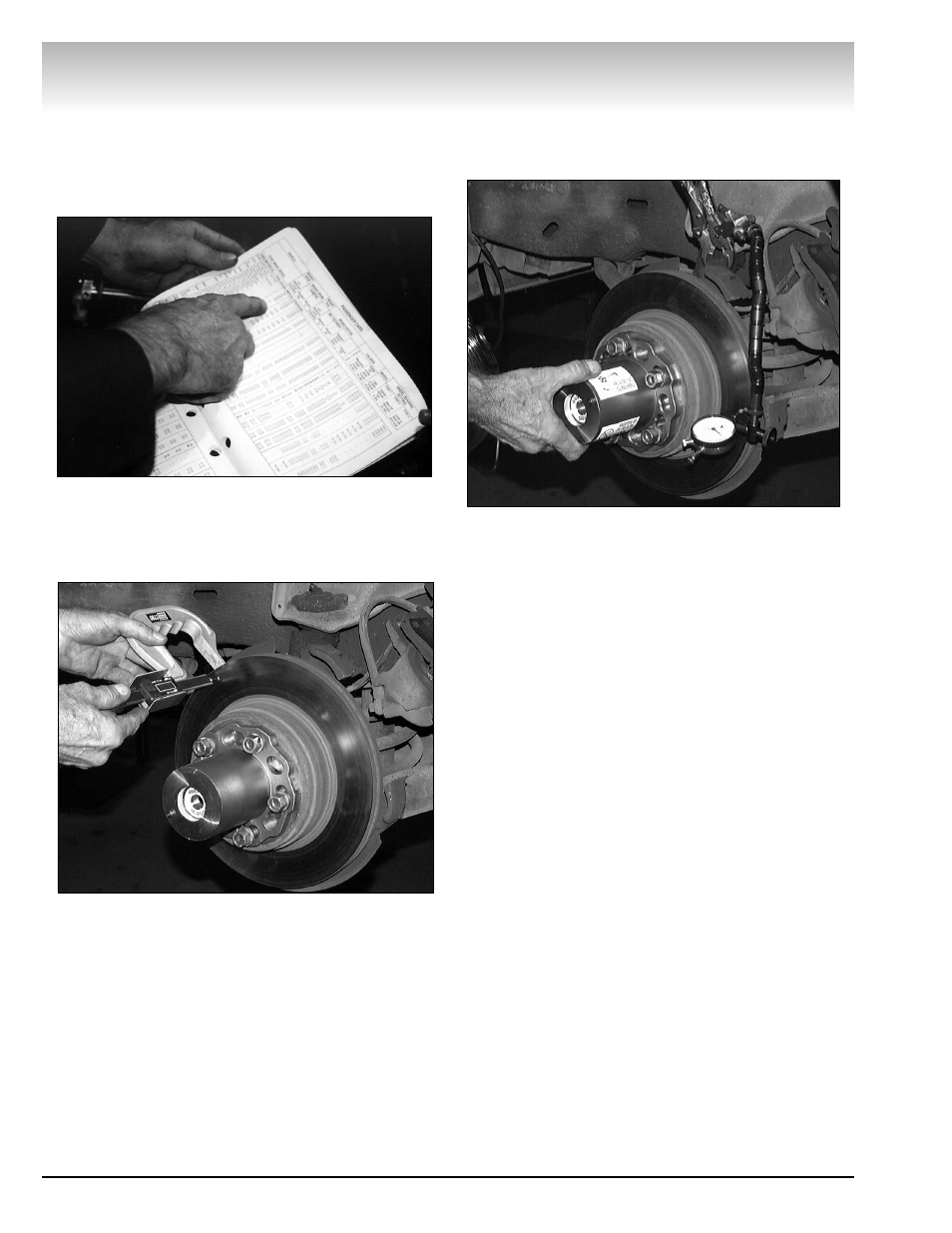

7.0 Before attempting any resurfacing, rotor

inspection is necessary. Determine the manufac-

turer’s rotor specifications from an approved specifi-

cation guide.

7.1 Using an AMMCO

®

model 2780 digital microm-

eter (p/n 902780) or other rotor-measuring tool, record

the thickness of the rotor. Observe any deep scores

and gouges, as this depth will also need to be

recorded.

7.2 Attach a dial indicator to the vehicle and record

the rotor runout. Refer to DIAL INDICATOR ASSEM-

BLY AND SET UP on page 10.

7.3 Determine if the total amount of material to be

removed will meet the manufacturer’s minimum spec-

ifications, if not a new rotor will be required. In all

cases, a new rotor must be inspected for runout and

sometimes resurfaced to meet manufacturer’s speci-

fications.

Note: Be aware that all vehicle manufacturers have a

minimum “machine to” and a “discard” thickness.