Oon n- -t th he e- -v ve eh hiic clle e, Caution – AMMCO 800 On-The-Vehicle Brake Lathe User Manual

Page 23

AMMCO 800 On-The-Vehicle Brake Lathe • 17

The mirror maybe used to view the rear surface.

11.31 After the scratch cut is performed reattach

the dial indicator to the target.

11.32 Read the runout. If runout is 0.004-inch or

less make no adjustments and proceed with the cut.

If the runout is more than 0.004-inch turn the power

switch off and re-engage the head lock pin (yellow).

11.33 Turn the power back on.

11.34 Use very small movements of the adjust-

ment knobs (red and blue) to decrease the indicator

movement to read less than 0.004-inch.

11.35 Switch power OFF. Disengage the head lock

pin (yellow) and move the indicator away from the tar-

get.

11.36 Proceed with cutting the rotor.

Note: It is not necessary to make another scratch

cut because the cutter head has not moved signifi-

cantly since the lock pin (yellow) was re-enaged.

11.4 Switch power ON. With both cutting tips

backed away from the rotor, advance the carbide

inserts toward the center of the rotor diameter, using

the feed handwheel, being careful not to run the car-

bide inserts into the hub portion of the rotor.

11.5 Reposition carbide inserts to the cleanup

position by turning each insert adjustment knob clock-

wise one revolution, plus 0.004-inch cut depth for

resurfacing each side of the rotor. Make sure the tool

holder locking levers are locked in place before engag-

ing feed.

Completing the Cut

For optimum results, once the automatic

feed is engaged, do not disturb the lathe or

stand during the cut or damage to the rotor

may result.

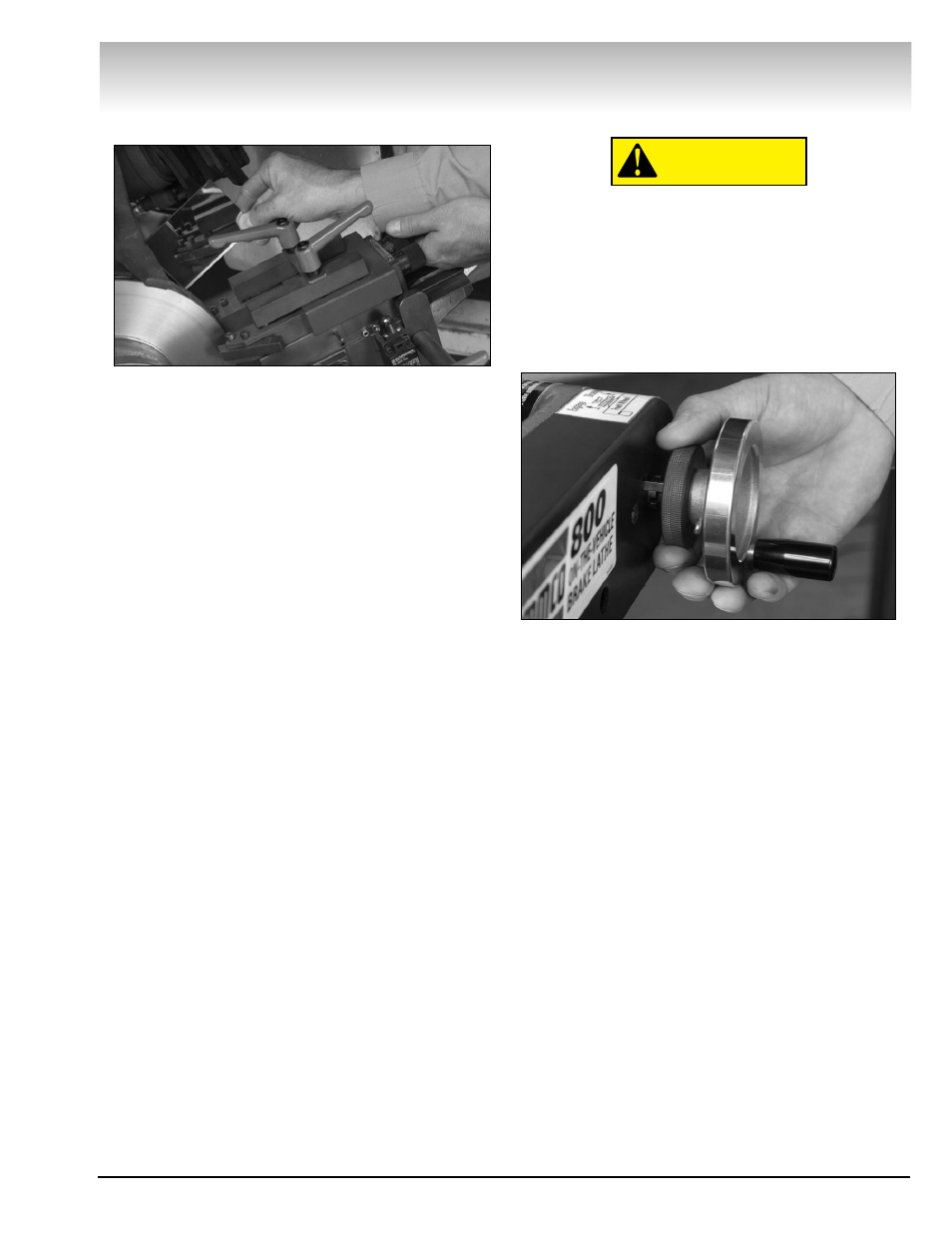

12.0 Engage feed by pushing the feed engage-

ment knob (gray) forward into the slots. It is located

just behind the feed handwheel. The 800 brake lathe

will now feed the carbide inserts outboard at the rate

of .004-inch per revolution of the lathe spindle.

CAUTION

O

On

n-

-T

Th

he

e-

-V

Ve

eh

hiic

clle

e