Brake lathes – AMMCO 3860 Drum & Disc Brake Lathe User Manual

Page 9

AMMCO 3850, 3860 Brake Lathes • 3

Brake Lathes

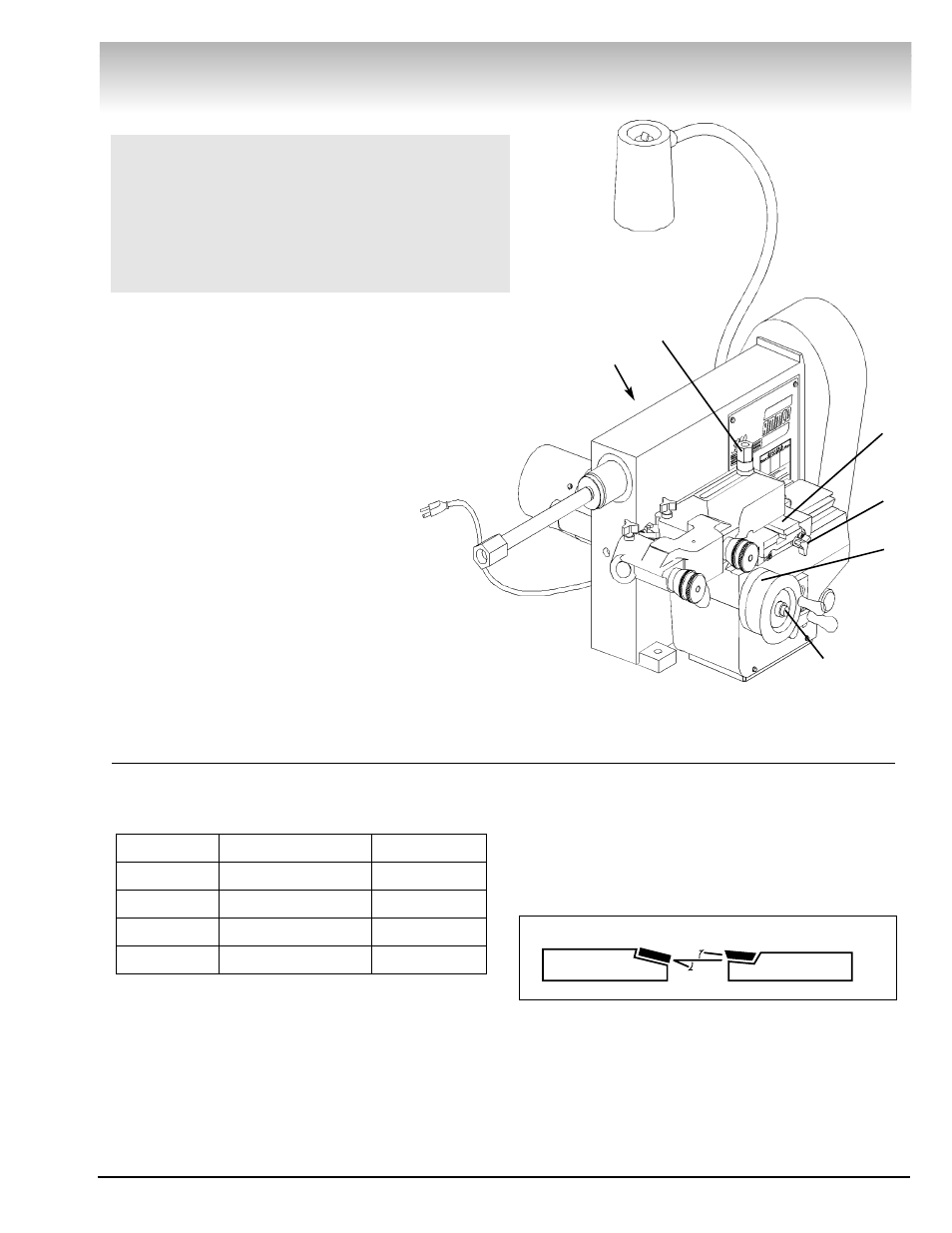

Principal Operating Parts

Ạ

Work Light

ạ

T-Bolt and Self-Aligning Hex Nut

Ả

Drive Motor (not seen in drawing)

ả

1"Arbor

Ấ

Arbor Nut

ấ

Power Cord

Ầ

Twin Cutter

ầ

Feed Handwheel

Ẩ

Feed Button

ẩ

Feed Engagement Lever

Ẫ

Depth-of-Cut Dial

ẫ

Slide Lock Knob

Ậ

Drive Belt Assembly Cover

ậ

Power Panel (with ON/OFF Switch)

Ắ

Tool Slide

ắ

Crossfeed

Operating Instructions

Negative and Positive Rake Tooling

3850

3860

BLACK

HOLDER

SILVER

POSITIVE

RAKE

NEGATIVE

6918

BIT

6914

0.005

MIN. CUT DEPTH

0.002

Making shallow cuts of less than .005 inches

greatly reduces the effective life of a positive rake

tool bit. Shallow cutting does not transfer heat

effectively from the bit to the rotor or drum, and

reduces the life of the bit. Shallow cuts also do not

allow the bit to dig enough, and may cause the bit

to break.

A negative rake tool bit angles downward from the

tool bit holder towards the brake surface. A positive

rake tool bit angles upwards from the holder towards

the brake surface (figure 1).

Figure 1 - Negative Rake Compared to Positive Rake

Note: Do not use positive bits on negative holders

or negative bits on positive holders!

Ạ

ạ

Ầ

Ả

ả

ấ

Ấ

Ậ

ẫ

Ẫ

ẩ

Ẩ

ầ

ậ

ắ

Ắ

Know Your Unit

Compare this illustration with the unit before placing it

into service. Maximum performance and safety will be

obtained only when all persons using the unit are fully

trained in its parts and operation. Each user should learn

the function and location of all controls. Prevent acci-

dents and injuries by ensuring the unit is properly

installed, operated, and maintained.

Negative Rake

Positive Rake

Up/Positive

Down

Negative

Tool Bit Holder

Tool Bit Holder