Brake lathes, Warning – AMMCO 3860 Drum & Disc Brake Lathe User Manual

Page 19

AMMCO 3850, 3860 Brake Lathes • 13

Brake Lathes

19. Turn the lathe on and move the tool bit in to the

rotor and make a second scratch cut. Back the tool bit

away and turn lathe off.

20. Inspect the scratch cuts.

If the cuts are side by side, the runout or wobble is

caused by the rotor condition. Use a dial indicator to

compare rotor runout with manufacturer’s specifica-

tions.

If the cuts are opposite each other (180° apart), the

rotor may not be mounted correctly. Remove the rotor

and examine the adapters for nicks, burrs, chips, dirt,

or rust. Inspect the rotor hub for loose or damaged

bearing cups. Clean, repair, remount, or replace as

necessary.

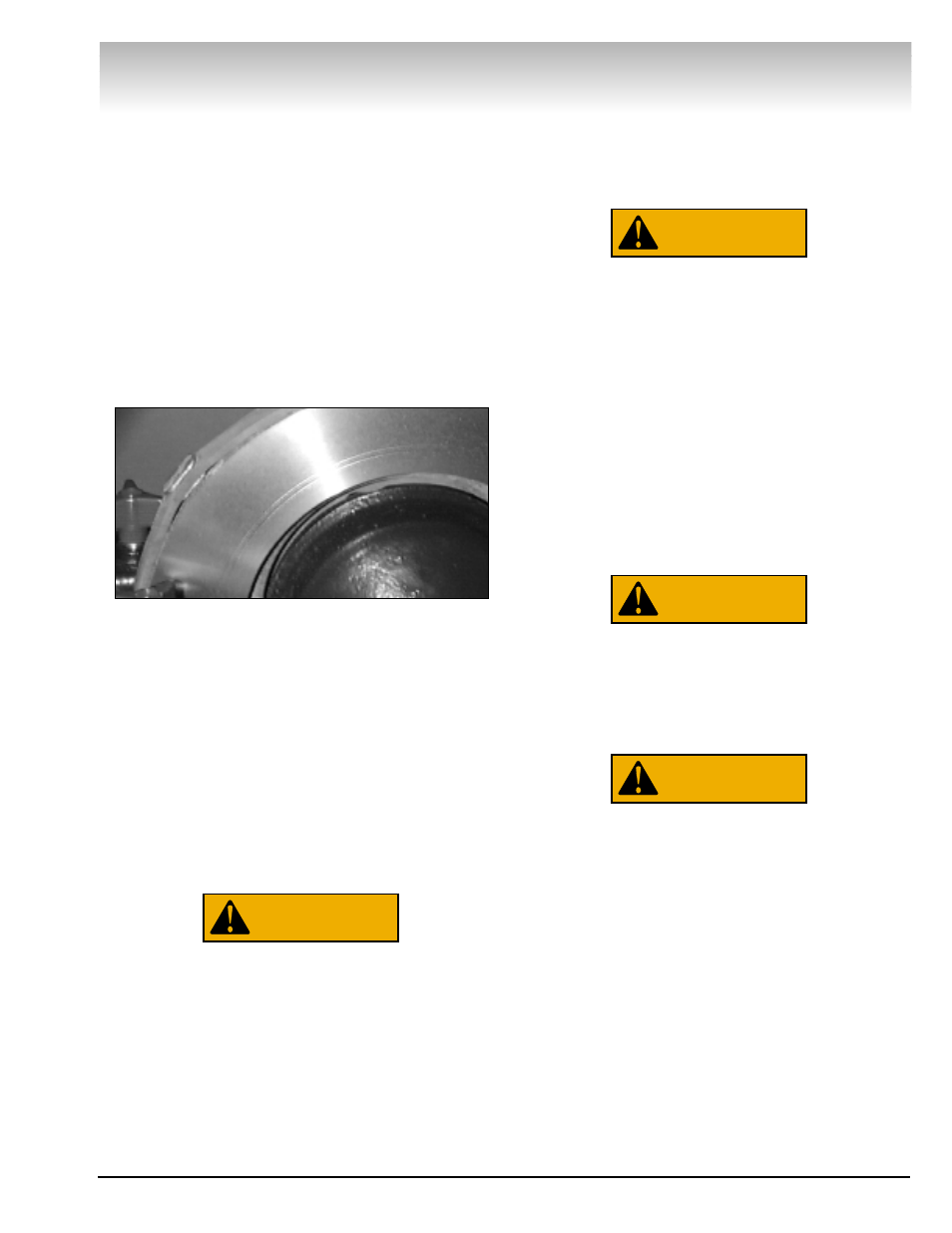

Figure 22 - Second Scratch Cut

21. Recheck the depth-of-cut collars that were set

to zero earlier. To compensate for runout, turn the

lathe on and move the tool bits in until they just just

scribe a line around the entire diameter. Depth-of-cut

collars should read zero. Reset as necessary.

22. Back the tool bits away from the rotor and turn

the lathe off. Turn the handwheel clockwise and move

the tool bits in towards the rotor hub.

Remember: The outside tool bit should reach all the

way in to just barely touch the rotor hat and the inside

tool bit should be positioned to clean the entire inner

surface.

Safety glasses, safety goggles, or face

shields must be worn during the recondi-

tioning process. Put them on before start-

ing the lathe.

23. Turn the lathe on. Use the handwheel in rotor

position to advance the outer tool bit in towards the

rotor to clean the rotor hat. Back the handwheel off a

half turn after hat is cleaned.

24. Dial both tool bit control knobs to zero and then

dial in an additional .005 inch minimum for positive

rake bits and .002 inch for negative rake bits depth-of-

cut. Lock them in place with the red lock knobs.

Important: Read and understand the description of

Negative and Positive rake bits on page 3.

Never operate the lathe with a worn or bro-

ken tool bit. This may cause the tool bit

holder to contact the drum or rotor surface.

The drum or rotor, as well as the tool itself,

may be damaged. Replace worn or broken

tool bits immediately.

25. Pull the engagement handle up to engage the

feed drive and move the tool bits outward across the

rotor surfaces. When the tool bits clear the edge of

the rotor, disengage the feed drive, turn the lathe off

and inspect the surfaces.

26. If either surface has not been completely

reconditioned by this first cut, reposition the tool bits

near the rotor hub, select new depth-of-cut, and make

a second cut across the rotor.

Keep rags and loose clothing away from an

operating lathe. Never wear gloves when

operating a lathe.These items may become

entangled in the arbor or spindle and pull

the operator into the lathe, causing per-

sonal injury.

Never operate the lathe without the pulley

cover securely in place over the drive belt

and pulleys. Operating the lathe without

this cover in place may cause `personal

injury.

WARNING

WARNING

WARNING

WARNING