Brake lathes, Warning caution – AMMCO 3860 Drum & Disc Brake Lathe User Manual

Page 18

Brake Lathes

12 • AMMCO 3850, 3860 Brake Lathes

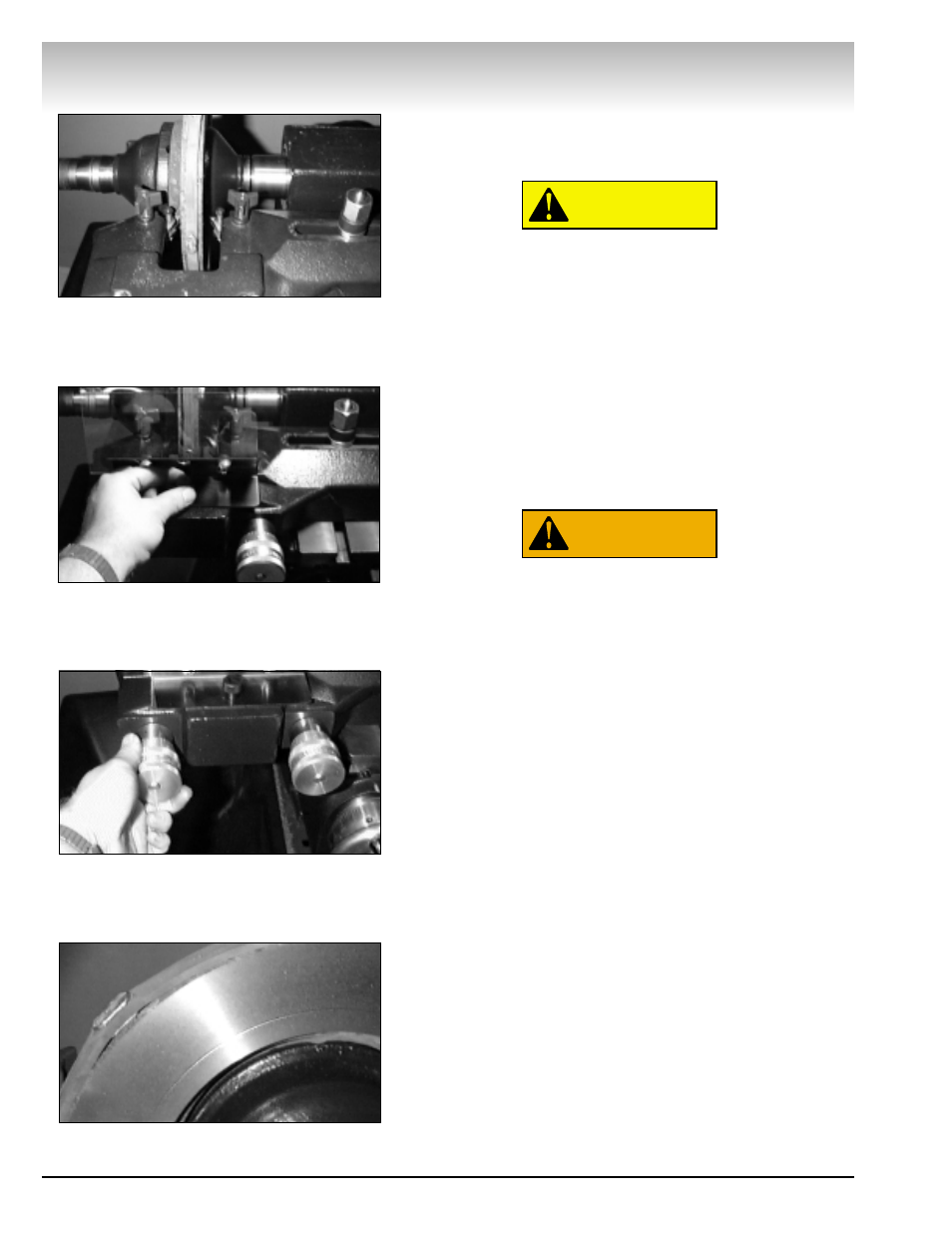

Note: Be sure to position twin cutter so the outside tool bit will

be able to just barely contact the rotor hat and the inside tool bit

will clean the entire surface.

Do not operate the lathe with twin cutter without

safety shield in place. It helps protect the operator

and bystanders from the metal chips and debris that

fly out from the cutter during machining.These chips

and cuttings may cause personal injury. Review the

safety instructions at the beginning of this manual

before proceeding.

9. Place the safety shield in position on top of the twin cutter

(if not already installed). Locate the thumb screw into the hole

in the twin cutter and tighten securely. Move shield down into

operating position.

10. Turn the tool bit knobs and advance the bits in until they

are next to, but not touching, the rotor surface.

Safety glasses, safety goggles, or face shields must

be worn during the reconditioning process. Put

them on before starting the lathe.

11. Make sure work area is clear. Turn the lathe on.

12. Turn a tool bit control knob clockwise to advance the tool

bit into the rotor. Move it in until it just touches the rotor surface.

13. Turn the depth-of-cut collar on the tool bit to zero, and

back the tool bit away from the rotor.

14. Repeat steps 12 and 13 for the other tool bit.

Important: From this point on, all tool adjustments will be

made with the tool bit controls. The depth-of-cut collars will be

the reference and should not be moved.

15. Place the handwheel in the rotor position. Turn the hand-

wheel counterclockwise and move the twin cutter in until the

tool bits are approximately at the mid point of the rotor surface.

16. Turn the left tool bit knob until the tool bit contacts the

rotor surface and makes a scratch cut. Back the tool bit away

and turn lathe off.

Note: The scratch will usually appear as an incomplete circle

around the rotor. This is caused by runout or wobble due to rotor

condition or improper rotor mounting.

17. Loosen the arbor nut and turn the rotor 180° on the

adapters. Do not allow the adapters to rotate along with the

rotor. Retighten the arbor nut.

18. Turn the handwheel counterclockwise a half turn to move

the tool bit away from the first scratch cut.

WARNING

CAUTION

Figure 18- Positioning Cutter Around Rotor

Figure 19 - Mounting the Safety Shield

Figure 20 - Adjusting Depth-of-Cut Collar

Figure 21- First Scratch Cut