Brake lathes, Caution – AMMCO 3860 Drum & Disc Brake Lathe User Manual

Page 14

8 • AMMCO 3850, 3860 Brake Lathes

Brake Lathes

11. Back the tool bit off, turn the lathe off, and

check the drum mounting. Loosen the arbor nut and

rotate the drum 1\2 turn (180°) on the arbor. Do not

allow adapters to turn with the drum. Retighten arbor

nut.

12. Place handwheel in drum position and turn

handwheel 1/2 turn in either direction. Turn the lathe

on, place handwheel in rotor position, advance the

tool bit to make a second scratch cut, back the tool bit

off, and turn lathe off.

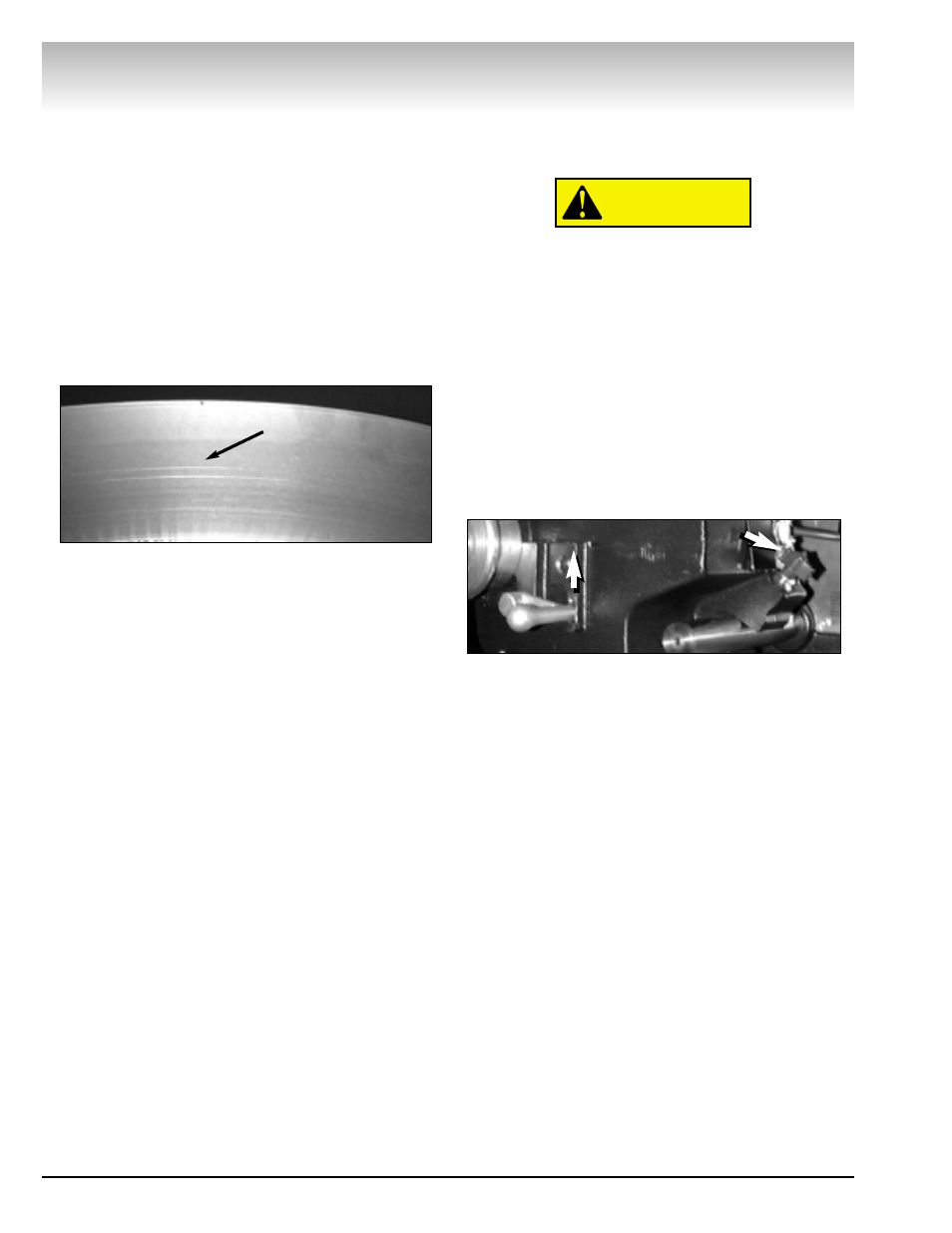

Figure 11 - Second Scratch Cut

If first and second scratch cuts are opposite on

another (180° apart), remove the drum from the

adapter. Check drum, adapters, and arbor for nicks,

burrs, or chips. Clean all mounting parts and surfaces

and remount the drum.

If scratch cuts are side by side, mounting is good and

the drum is ready for reconditioning.

13. Turn lathe on and position the tool bit so it just

touches the drum surface. Move handwheel to drum

position and turn it clockwise to advance the tool bit to

the inside corner of the drum.

14. Move handwheel to rotor position and note the

number graduation on the handwheel that is aligned

with the etched mark on the crossfeed. Rotate the

handwheel counterclockwise to dial in the desired

depth-of-cut. Cuts may be taken at depths of 0.005 to

0.020 inches (.010 to .040 inches on diameter gradu-

ated handwheel).

Determine depth-of-cut setting by adding the desired

depth-of-cut to the number graduation aligned with

the mark on the crossfeed. For example, if .010 is

aligned with the mark, and you wish to make a .020

inch cut, rotate the handwheel counterclockwise until

.030 is aligned with the mark.

Important: Read and understand the description of

Negative and Positive Rake bits on page 3.

Never operate the lathe with a worn or bro-

ken tool bit. This may cause the tool bit

holder to contact the drum or rotor surface.

The drum or rotor, as well as the tool itself,

may be damaged. Replace worn or broken

tool bits immediately.

Note: The micrometer depth-of-cut dial is calibrated

for drum diameter.

Important: Care must be taken to check actual drum

diameter before reconditioning so that the maximum

rebore limit established by the manufacturer is never

exceeded.

15. Tighten the crossfeed slide lock knob.

Figure 12 - Lock Slide and Engage Feed

16. Place the handwheel in the drum feed position.

17. Lift engagement lever to engage the drive and

begin the cut.

18. When the tool bit clears the outer edge of the

drum surface, push the engagement lever down to

stop the feed.

19. Turn the lathe off and inspect the drum. Do not

remove the drum from the lathe.

20. If the first cut has not cleaned the entire brake

surface, leave the tool bar locked in position. Turn the

lathe on and slowly turn the handwheel clockwise to

move the tool bit back into the drum. Advance until

the tool bit touches the bottom of the drum and

scrapes. Turn the handwheel counterclockwise until

the scraping stops. Repeat steps 14 through19.

21. Remove the reconditioned drum, spacers, and

adapters from the lathe. Clean metal and cutting

debris from the adapters, spacers, arbor, and lathe.

CAUTION

MODEL 3850 ONLY

(STEPS 11 THRU 21)

Tighten Lock Knob

Lift to

Engage Feed