Brake lathes, Warning caution – AMMCO 3860 Drum & Disc Brake Lathe User Manual

Page 13

Brake Lathes

AMMCO 3850, 3860 Brake Lathes • 7

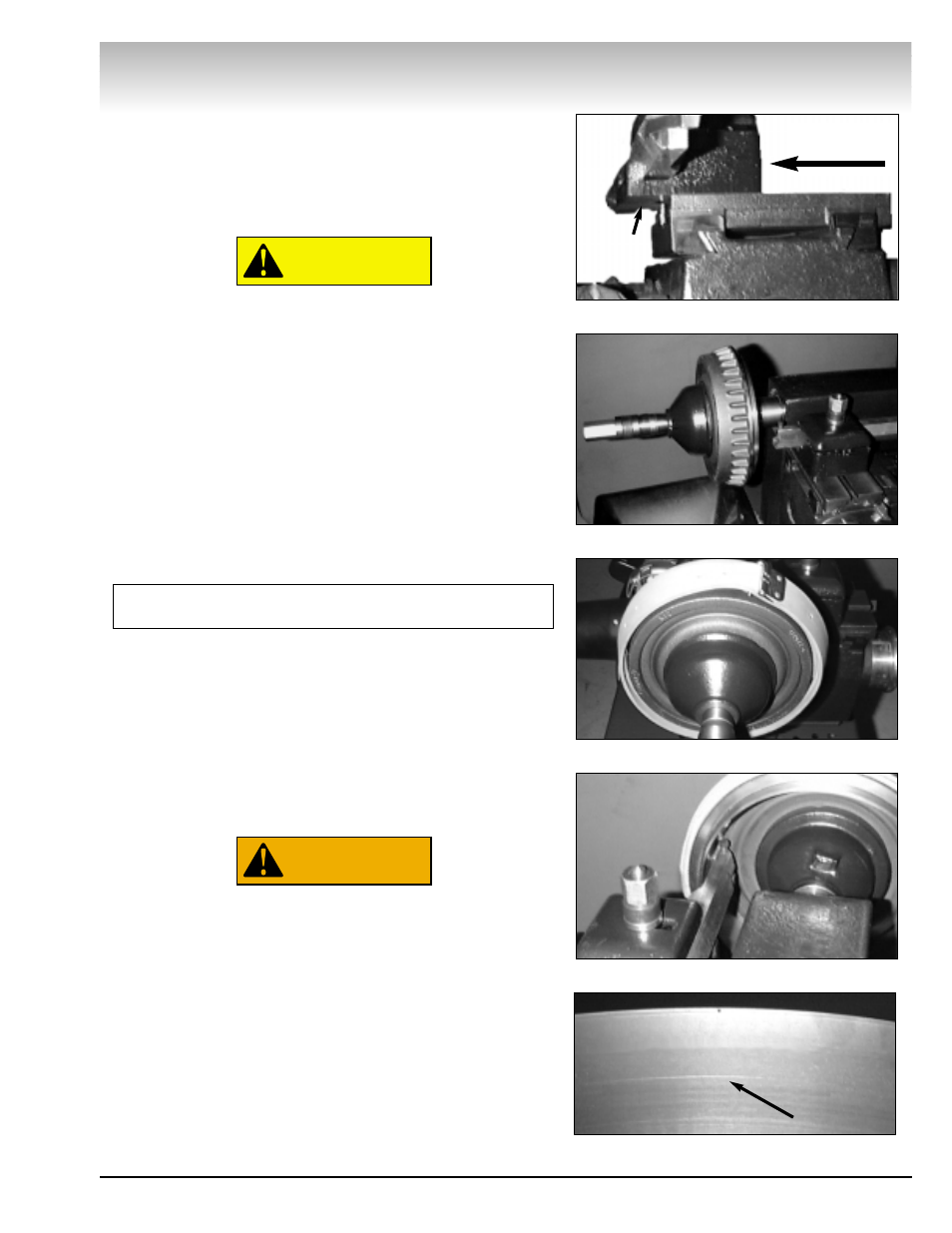

Important: Never position the boring bar clamp so it over-

hangs the tool slide. This causes the T-bolt to move too close to

the edge of the slide. Tightening the self-aligning nut down on

the T-bolt in this position can break the T-bolt ways, making the

lathe inoperable, damaging the work in process, and creating an

unsafe situation.

Never operate the lathe with the boring bar clamp or

twin cutter mounted to the tool slide so that they

overhang the slide. Damage to the lathe and work in

process may occur.

4. Position the crossfeed by moving handwheel to rotor posi-

tion and turning the handwheel clockwise to the “full in” posi-

tion. Rotate the handwheel counterclockwise a full 2 turns to

back the feed out into position.

5. Position the tool slide by placing the handwheel in the drum

position and turning the handwheel clockwise to move the tool

slide to the “full left” position. Turn the handwheel one full turn

counterclockwise to position the slide.

6. Wrap the drum silencer band snugly around the drum. The

band must fully cover the outside of the drum (Figure 8).

(3860 ONLY) Turn the end knob of the tool bar counterclock-

wise until the tool bit is fully retracted.

7. Move the boring bar until the tool bit is located in the inside

corner of the drum. The tool bit should be next to, but not touch-

ing, the drum surface. Tighten the self-aligning nut to 50 foot

pounds (a good one-handed pull on the wrench).

Note: With the self-aligning nut left loose, the boring bar has 3

inches of travel front-to-back for use in positioning the tool bit.

8. Turn the handwheel counterclockwise to move the tool bit

to the middle of the drum surface. Rotate the drum by hand and

check for clearance all the way around the drum.

Always wear eye and face protection when working

around an operating lathe. Metal chips and frag-

ments may be thrown from a spinning drum or rotor,

causing personal injury.

9. Clear lathe and work area of all foreign material, tools and

shop rags, then turn lathe on.

10. Place crossfeed handwheel into rotor position. Turn hand-

wheel and advance the tool bit until it contacts the drum and

makes a scratch cut.

WARNING

CAUTION

Figure 6 - Improper Boring Bar Mounting

Figure 7 - Drum and Boring Bar Mounted on Lathe

Figure 8 - Wrap Silencer Band Around the Drum

Figure 9 - Positioning the Boring Bar

Figure 10 - First Scratch Cut

Boring Bar Clamp

Too Far Over

Overhangs

Tool Slide