Brake lathes, Caution – AMMCO 6000 Heavy Duty Drum/Disk Lathe User Manual

Page 7

Installation

Receiving

The shipment should be thoroughly inspected as soon as it is

received. The signed bill of lading is acknowledgement by the

carrier of receipt in good condition of shipment covered by our

invoice.

If any of the goods called for on this bill of lading are shorted or

damaged, do not accept them until the carrier makes a notation

on the freight bill of the shorted or damaged goods. Do this for

your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or damage

is discovered after receipt and request the carrier to make an

inspection. If the carrier will not do so, prepare a signed state-

ment to the effect that you have notified the carrier (on a specific

date) and that the carrier has failed to comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER

YOU HAVE GIVEN THE CARRIER A CLEAR RECEIPT.

File your claim with the carrier promptly. Support your claim

with copies of the bill of lading, freight bill, invoice, and photo-

graphs, if available.

Although AMMCO’s responsibility ceases upon delivery of the

shipment to the carrier, we will gladly assist in tracing lost ship-

ments. Our willingness to assist in every possible manner does

not make AMMCO responsible for collection of claims or

replacement of lost or damaged materials. Shipping damage

claims will not be handled under warranty.

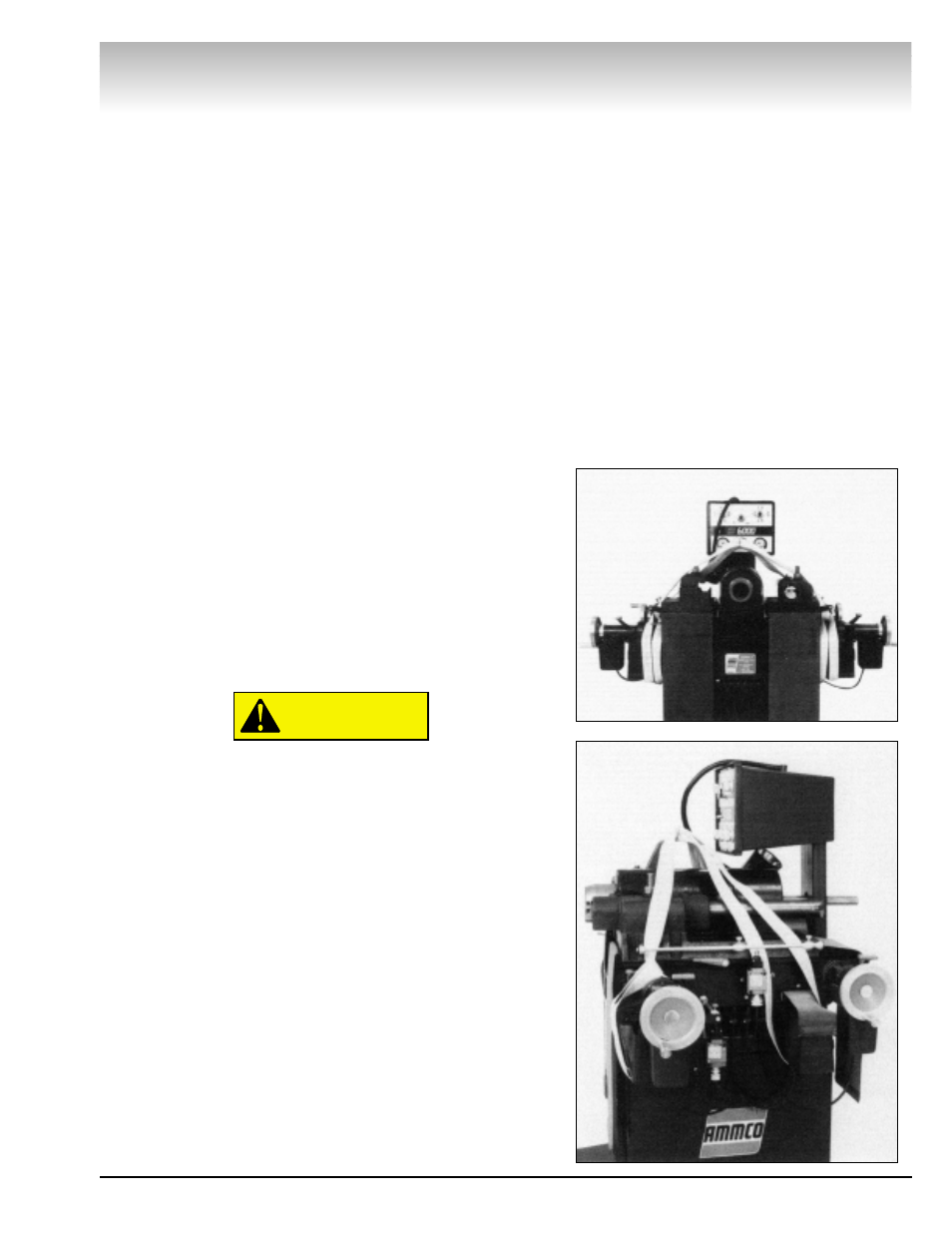

Preferred Lifting Method

Lift the lathe by all four bed ways only. DO NOT lift

under the saddles, cross slides, boring bars, or spin-

dle. Be sure the gearbox control wires and external

travel controls will not be damaged when lifting the

lathe.

Be sure the lifting slings are arranged so they will not crush or

exert pressure against any limit switch control parts, lock levers,

control wires, etc.

Both slings should be hung together in a hook or a loop of chain

when lifting the lathe.

Installation

Bolt the lathe to the floor using the anchor bolts provided. Be

sure the lathe is resting solidly on its three feet. Shim with wash-

ers if necessary to eliminate rocking. After the lathe is bolted

down run the outer corner screws of the front support down

until they contact the floor and tighten the jam nuts. These

screws are not to be used for leveling. BEFORE RUNNING THE

LATHE, REFER TO THE OILING AND GREASING INSTRUC-

TIONS. Allow sufficient work space around the lathe as illus-

trated in the WORK SPACE REQUIREMENTS.

CAUTION

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 1