Brake lathes – AMMCO 6000 Heavy Duty Drum/Disk Lathe User Manual

Page 15

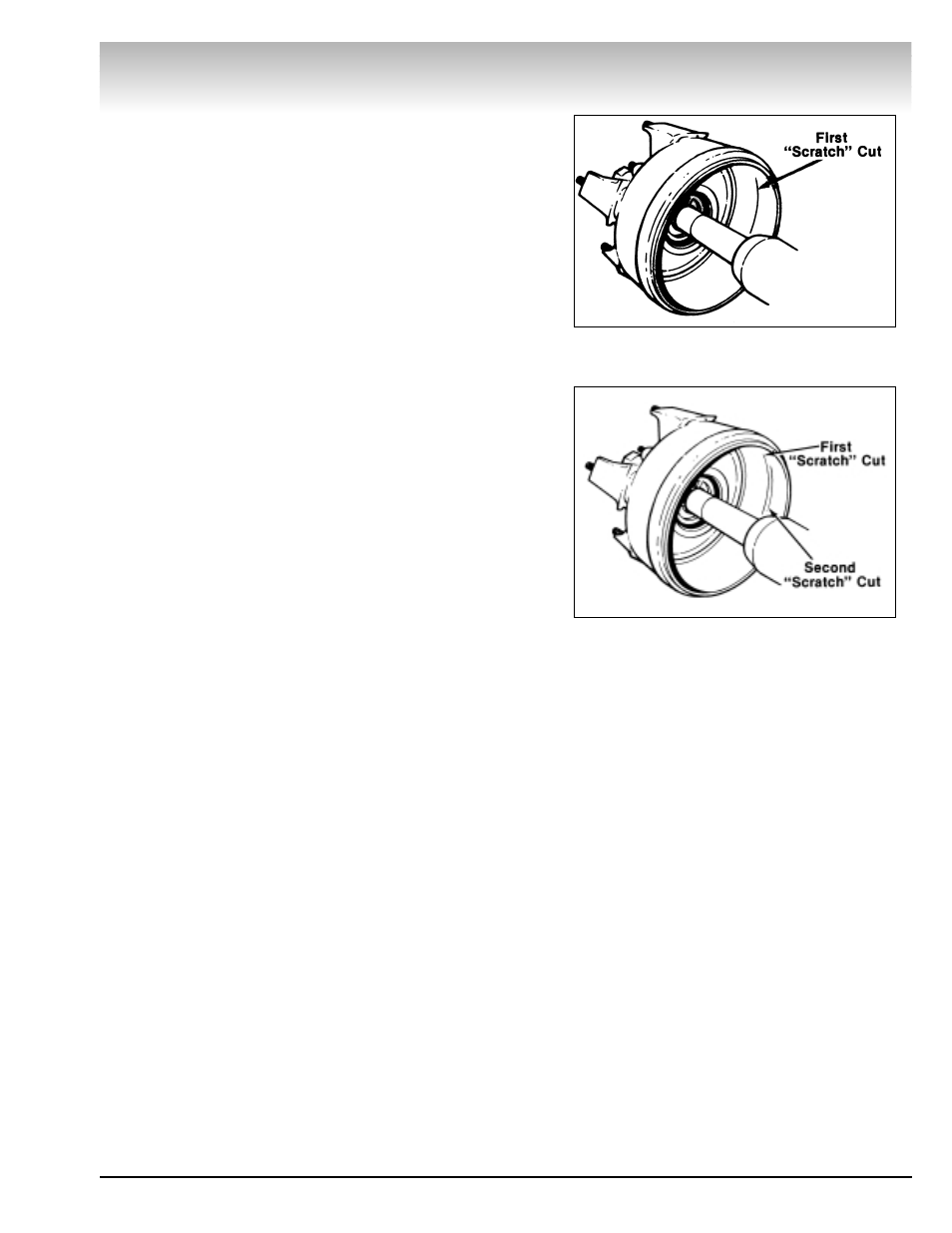

Note: A “scratch” cut should be no more than .001" deep. If

the “scratch” cut is too deep it will show a continuous line on

the face of the drum and the runout will not be apparent. Back

the tool bit off, stop the lathe, and check the mounting as fol-

lows:

A. Loosen the arbor nut and rotate the drum one-half turn

(180º) on the adapters.

Note: The adapters must be held to keep them from turning.

Retighten the arbor nut, turn the lathe ON, and make a second

“scratch” cut. Turn the lathe OFF.

B. If the first and second “scratch” cuts are side-by-side,

the runout is in the drum — not in the mounting.

Note: A very small amount of runout is permissible. A large

amount of runout indicates either a bent drum or an incorrect

mounting.

If the “scratch” cuts are opposite each other (180° apart), the

drum is not properly mounted. Shut the lathe OFF. Inspect the

mounting for cleanliness and the adapters for burrs, nicks, or

scratches. Check the bearing races for looseness. Remount the

drum and check again for runout. Proceed to machine the drum,

if the runout has been corrected.

9. Turn the lathe ON. Carefully advance the tool bit by hand

until it just contacts the drum surface and makes a "scratch" cut.

Hold the saddle hand wheel in this position and rotate its dial to

the (0) position. This setting will be the reference used to help

determine the reconditioned diameter of the drum.

10. Align the tool bit with the deepest groove worn in the

drum. Start the lathe and manually advance the tool bit into the

bottom of the groove until it makes a continuous cut around the

drum. Do not cut any deeper than necessary to make the cut

continuous. The depth-of-cut dial will show the approximate

amount of material that must be removed to recondition the

drum. Double the depth-of-cut reading and add the result to the

brake drum micrometer reading to find the finished diameter of

the reconditioned drum. This calculated measurement must be

compared with:

a. The maximum rebore limit (available from the

manufacturer’s specifications).

b. The measured diameter of the drum before machining to

determine the amount of material to be removed in each

pass.

11. With the lathe still running, give the saddle hand wheel

one full turn clockwise to move the tool bit away from the drum

wall. Manually position the tool bit at the inside corner of the

drum and set the desired depth of cut. Engage the feed gearbox

and set the feed speed.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 9

Figure 4 - Drum Mounting, First “Scratch” Cut

Figure 5 - Drum Mounting, Second “Scratch” Cut