Brake lathes, Maintenance and service – AMMCO 6000 Heavy Duty Drum/Disk Lathe User Manual

Page 20

Maintenance and Service

Oiling

The lathe is initially greased and the bare metal parts are

coated with an oil-soluble rust preventative at the factory. It is

not necessary to clean the rust preventative from these parts.

Before using the lathe, however, all bare metal parts (ways,

spindle, cross slides, etc.) should be wiped down with an oiled

rag. Use a light machine oil or way oil for the initial wipe down

and daily when oiling the bare metal parts. Keep the wipers

oiled by applying light machine oil to their top edges daily.

Greasing

Automotive chassis grease should be applied to the grease fit-

tings called out in Figs. 1, 2 & 3 weekly using the hand grease

gun supplied with the lathe.

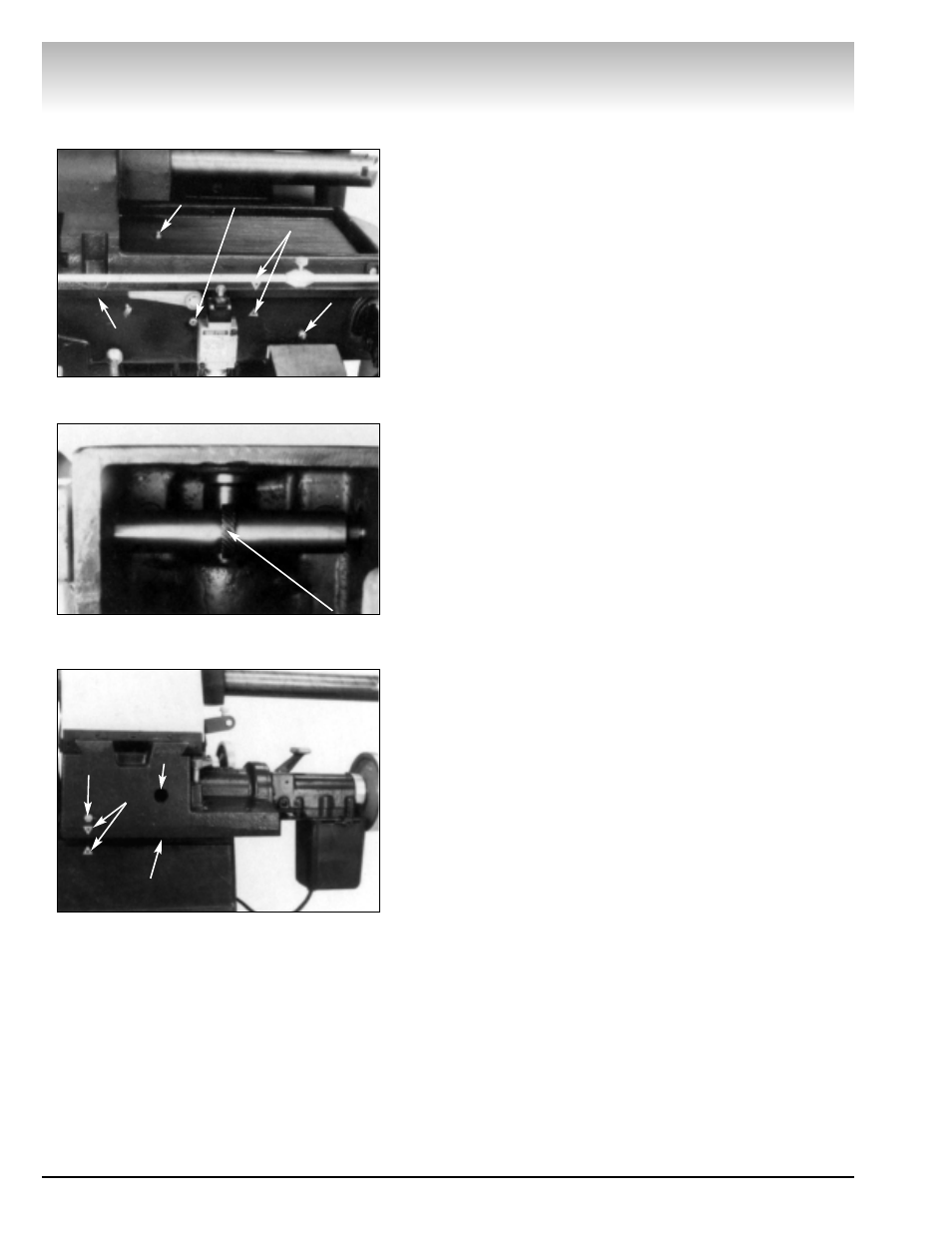

Sides (Right Side Illustrated), Fig. 1:

Align the red triangle index marks (1). Apply grease to the lead

screw nut fitting (2) located on top of the cross feed. Also,

grease the cross slide way fitting (3) and the rear saddle way fit-

ting (4). Follow the same procedure when greasing the left side.

Rear (Right Rear Illustrated), Fig. 2:

With the lathe turned OFF, reach up under each saddle at the

back of the lathe and wipe grease onto the driving shaft gears

of the cross slide gear boxes.

Front (Front Right Illustrated), Fig. 3:

Fold the cross slide dove tail cover back. Align the red triangle

index marks (5). Apply grease to the saddle fitting (6) and the

lead screw nut fitting (7) located inside the hole in the front of

the saddle. Follow the same procedure when greasing the front

left side.

Motor Bearings: The motor bearings are sealed for life and

need no maintenance.

Cleaning

Keep the lathe as clean as possible for trouble free operation

as well as safety and longer lathe life. Use a brush to sweep

metal chips and dust off the lathe. DO NOT USE COMPRESSED

AIR TO BLOW THE LATHE CLEAN as chips and dust may be

driven between machined parts and into bearings, and cause

undue wear.

Adjusting Gibs

The gibs, Figs. 1 & 3, should be adjusted periodically to mini-

mize looseness in the slides and to obtain the best possible fin-

ish on the work. When adjusting the gibs, the cross slide and

the saddle must not overhang either end of their respective

dove tails. Tighten one gib adjusting screw then back it off until

the slide moves smoothly. Run the slide back and forth by hand

to check your adjustment. Repeat a second time if necessary.

Go through the same procedure for each individual gib adjusting

screw.

Brake Lathes

14 • AMMCO 6000, 6002 Brake Lathes

Figure 1 - Grease Fittings (Right Side Shown)

Figure 2 - Apply Grease To The Gear (Right Rear

Shown From Underneath)

Figure 3 - Grease Fittings (Right Front Shown)

Cross Slide Gib

Saddle Gib

1

2

3

4

5

6

7