Brake lathes – AMMCO 6000 Heavy Duty Drum/Disk Lathe User Manual

Page 19

adjustable stop depresses the microswitch plunger. Tighten the

lock screw to hold the stop at this point.

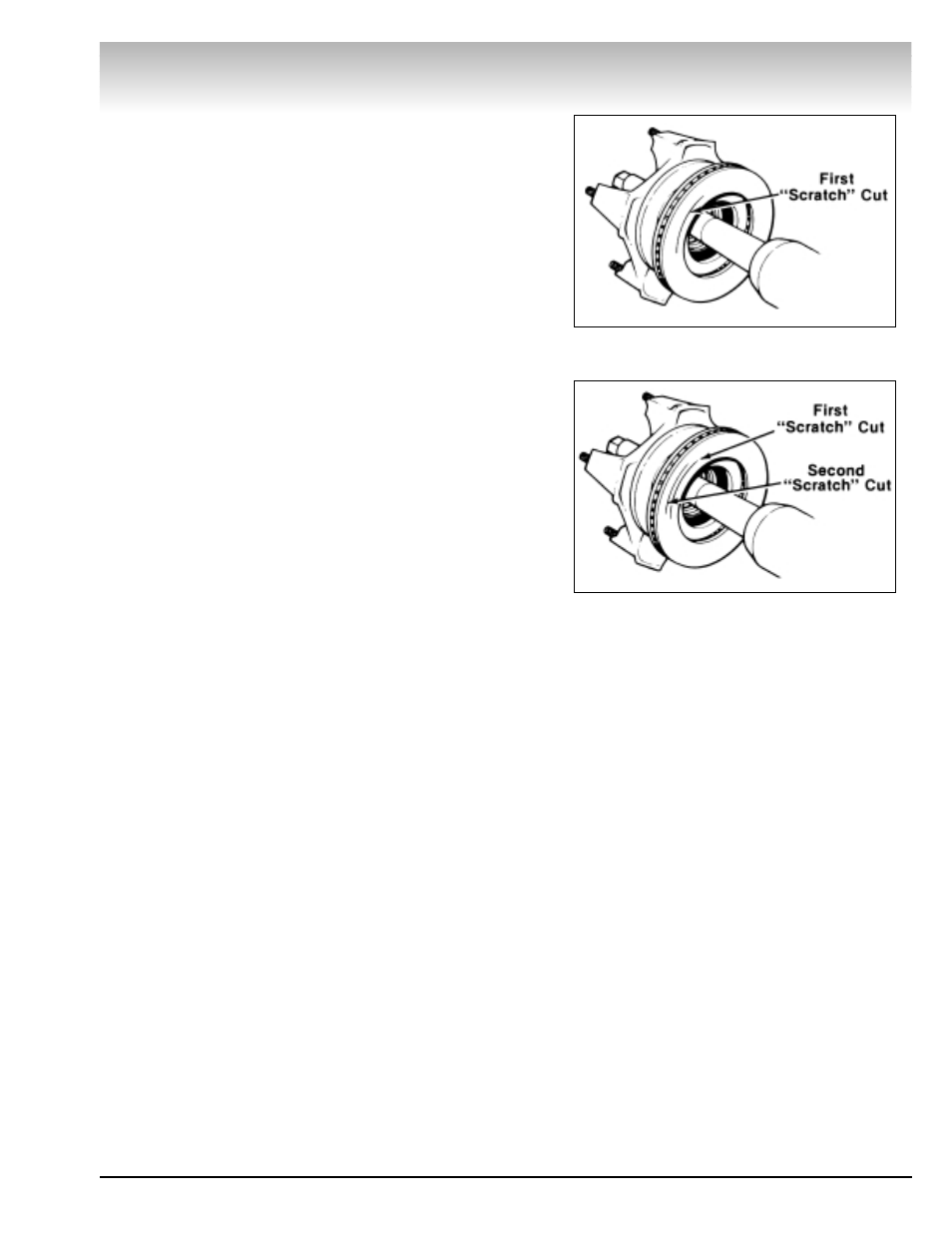

9. Advance the tool bits to the approximate center of the rotor

faces. Turn the red and blue depth-of-cut knobs clockwise, one

at a time, until their respective tool bits make light contact with

the rotor face, making a “scratch” cut, Fig. 7.

Note: A “scratch” cut should be no more than .001" deep. If

the “scratch” cut is too deep it will show a continuous line on

the face of the rotor and the runout will not be apparent. Hold

the outer knobs still and turn the inner dials to zero (choose

either inches or millimeters). Back the tool bits away from the

rotor by turning the knobs counterclockwise. Turn the lathe OFF.

10. To check the rotor mounting:

A. Loosen the arbor nut and rotate the rotor one-half turn

(180°) on the adapters.

Note: The adapters must be held to keep them from turning.

Retighten the arbor nut. Back the saddle out one hand wheel

turn and start the lathe. Make a second “scratch” cut on the

outer surface of the rotor only. Turn the lathe OFF.

If the “scratch” cuts are side by side any runout or wobble is

caused by the rotor’s condition.

B. If the “scratch” cuts are opposite each other (180º

apart), the rotor is not properly mounted. Remove the rotor

from the arbor and examine each adapter and the arbor for

nicks, burrs, chips, dirt, and rust. Also inspect the rotor hub

for loose or damaged bearing cups. Clean, repair, remount,

or replace as necessary.

11. Check the settings of the depth-of-cut dials again. Move

the tool bits in until they lightly contact the rotor faces and reset

the dials to zero if necessary.

12. Start the lathe and manually advance the saddle to posi-

tion the outer tool bit at the rotor hub. Set the dial knobs for the

desired depth of cut (inches or millimeters). Set the spindle

speed and set the left hand feed direction knob to the FACE CUT

OUT position. Engage the saddle feed gearbox.

Note: The following spindle speed and feed speed recom-

mendations are intended to serve as a starting point for a

machine operator not familiar with the lathe.

Rotors

Spindle Speed

Feed Speed

Up To 12" Dia.

Fast

Medium Slow

Over 12" Dia.

Medium

Medium Slow

Note: See CONTROL PANEL FUNCTIONS.

Although these settings are relatively slow they should give

the manufacturers recommended finish and good tool life. The

settings shown may be increased considerably; however, tool

life decreases as spindle speed and feed speed are increased.

When the cut is completed, disengage the feed gearbox and

shut the lathe OFF.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 13

Figure 7 - Rotor Mounting, First “Scratch” Cut

Figure 8 - Rotor Mounting, Second “Scratch” Cut