Advance adapters inc. p/n: orion – Advance Adapters Orion Transfer Cace User Manual

Page 10

ADVANCE ADAPTERS INC.

P/N: Orion

PAGE 10 OF 15

Page Rev. Date:

04-18-05

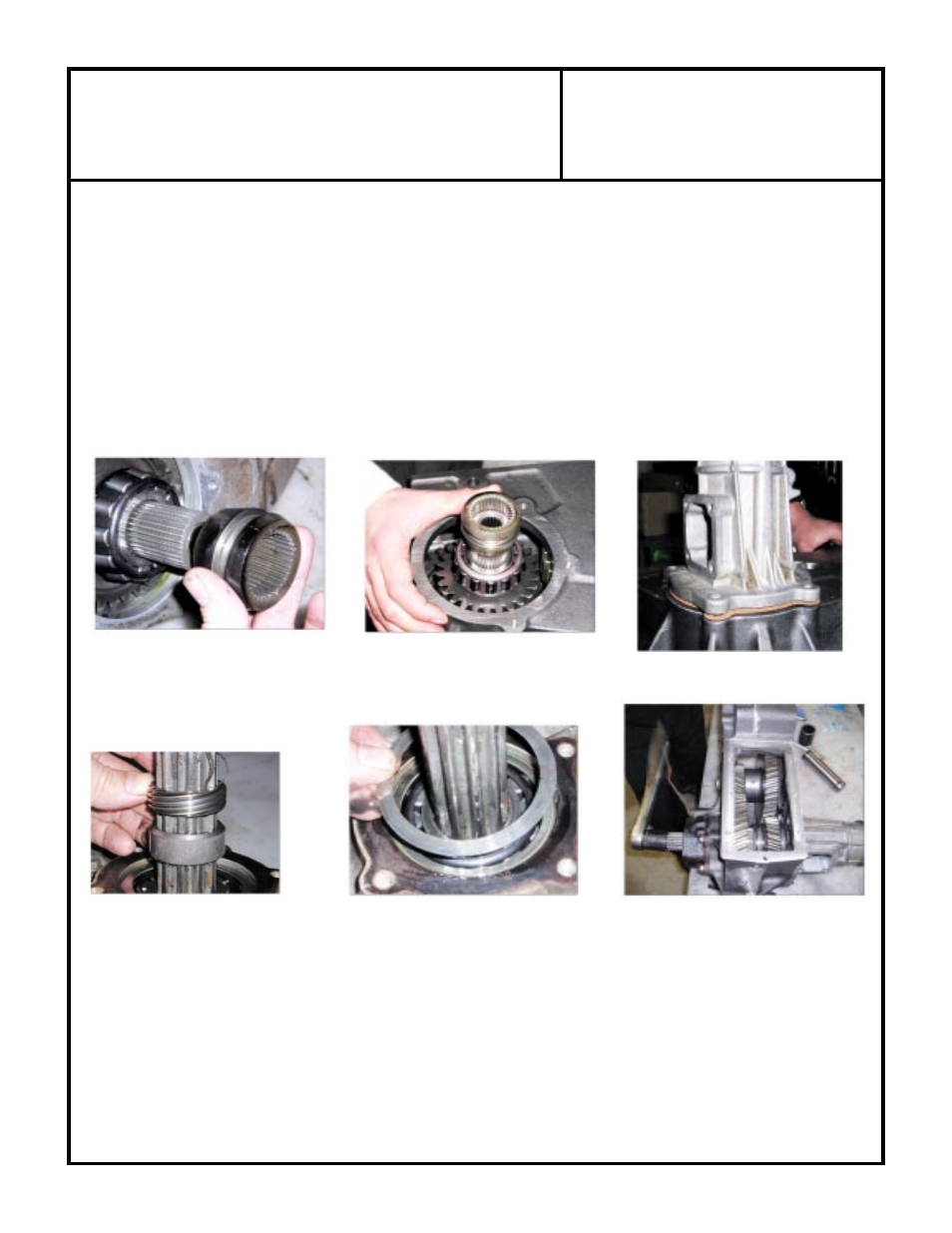

Apply assembly lube and place low speed output gear G28 and HI and LOW clutch sleeve G26 in position within the

case. Install output shaft assembly G25 into the case. Install stock thrust washer G29 and rear tapered roller bearing

G30 onto output shaft G25. Lightly drive rear tapered roller bearing using a dead blow hammer and P/N 400250 tubular

bearing tool (make sure bearing is seated). Again, only drive against the inner race of the bearing.

If you have not done so, install tapered roller bearing cups G21 and G30 into the Orion case, and extension housing C28

in addition to ball bearing G17, snap ring G16, and seal C26.

Lubricate the seal lip and install output front shaft G18 into the extension housing C28. Install front yoke, washer, and

nut, Items C20-C22 or C23-C25. Tighten nut. Torque range will be 101-123 ft./lbs.

Install extension housing assembly C28, gasket C29, and the front drive clutch sleeve G26 onto the case.

Gasket C29

must be used. Do not use any other gasket substitute.

Be sure to assemble the front drive clutch sleeve with

the tapered side of the sleeve towards the rear of the case. Tighten extension housing bolts to 7-11 ft./lbs. of torque.

Re-assemble transfer front drive shift assembly:

Vacuum-

Diaphragm cylinder and transfer front drive fork

Mechanical-

Transfer front drive shift shaft guide assembly

Included in your Orion kit are 8 adjusting shims in varied thicknesses. Place bearing adjusting shim(s) G31 in position

on the output shaft rear bearing cup G30. Install output shaft rear bearing retainer C4 and gasket C3.

Gasket C3

must be used. Do not use any other gasket substitute.

Tighten retainer bolts to 7-11 ft./lbs. of torque.

Use nut C10 or C8 and run the nut down tight until it stops on output shaft G25.

Do not use the cotter pin or stake

the nut.

The HI and LOW clutch sleeve must be in the neutral position and the front drive disengaged. Check the

output shaft bearing pre-load by turning the shaft, if using a torque wrench on nut C10 or C8.

The output shaft must

have a resistance of 10-20 in./lbs. of torque. If using a fish or pull scale coupled to a brake drum

bolt a 10 to 13 pound measurement should be obtained.

If necessary, adjust the pre-load by selecting a

new shim(s).

Improper bearing pre-load setting may cause bearing and/or transfer case failure.

Slide spacer G32 and speedometer gear

G33 onto the output shaft.

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.