Chapter 8 – operation, Cold weather start up, Engine cold weather start kit – Snorkel TB50 User Manual

Page 55: Cummins, kubota and ford – block heater, Cummins – ether injection, Danger

TB42/TB50 – 0074923

51

Chapter 8 – Operation

The aerial platform may be operated from either the

lower or upper controls.

Danger

The aerial platform is not electrically insulated.

Death or serious injury will result from contact

with, or inadequate clearance from, an energized

conductor. Do not go closer than the minimum safe

approach distance as defined by ANSI.

Pinch points may exist between moving compo-

nents. Death or serious injury will result from be-

coming trapped between components, buildings,

structures, or other obstacles. Make sure there is

sufficient clearance around the machine before mov-

ing the chassis, booms, or platform. Allow sufficient

room and time to stop movement to avoid contact

with structures or other hazards.

The aerial platform can tip over if it becomes un-

stable. Death or serious injury will result from a tip-

over accident. Operate the aerial platform on a firm,

flat, level surface. Avoid travel speeds and/or rough

terrain that could cause sudden changes in platform

position. Do not drive or position the aerial platform

for elevated use near any drop-off, hole, slope, soft

or uneven ground, or other tip-over hazard.

The platform rated work load is the total weight of the

personnel and equipment that may be lifted in the

platform.

The work loads are stated on the platform rating placard

at the:

rear of the platform

lower controls

upper controls

Danger

The aerial platform can tip over if it becomes un-

stable. Death or serious injury will result from a

tip-over accident. Do not exceed the capacity values

indicated on the platform rating placard.

Capacity values indicate the rated lifting capacity and

do not indicate aerial platform stability.

The operator bears ultimate responsibility for ensuring

that the aerial platform is properly set up for the particular

conditions encountered.

Cold Weather Start Up

If the ambient temperature is 32°F (0°C) or below, the

engine and hydraulic system oil may need to be warmed

up before operation. Do not operate the engine at more

than a fast idle until the engine and hydraulic oil has had

a chance to warm. The engine may be equipped with

an optional cold weather start kit.

Cold, thick hydraulic oil does not flow well and may

cause delay in response to control movement and

improper voltage output of the optional AC generator.

Cold hydraulic oil may also cause cavitation and pump

damage. The hydraulic system may be equipped with

an optional cold weather warm-up kit.

Engine Cold Weather Start Kit

The optional engine cold weather start kit may be an

engine block heater or a radiator hose in-line heater. The

type of starting assist system depends on the engine

manufacturer.

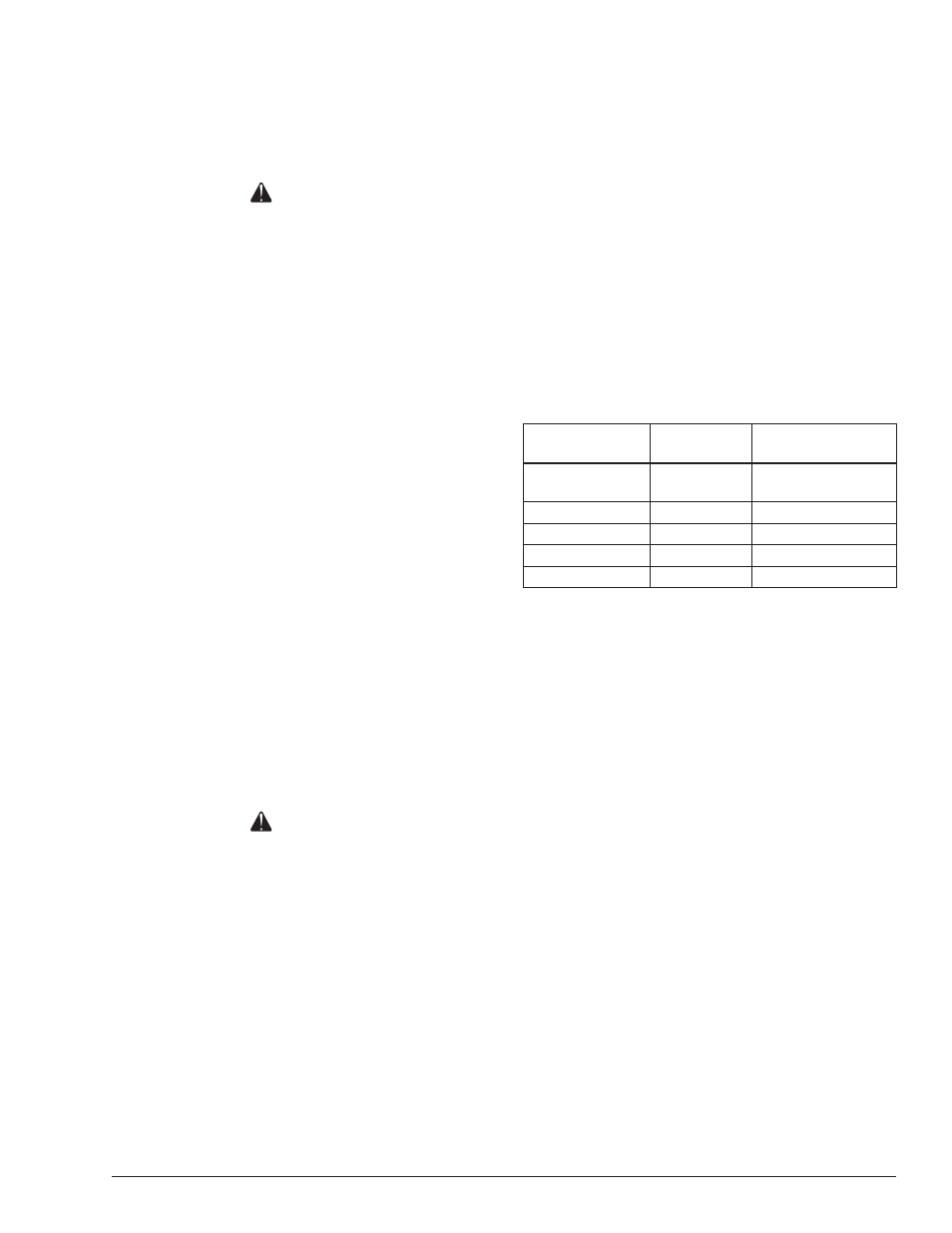

The last two letters of the model number stamped on the

serial number placard indicates the engine manufacturer

(refer to Figure 8.1).

Last Two Letters

of Model Number

Engine

Manufacturer

Cold Weather

Start System

CU

Cummins

Engine block heater

or ether injection

DZ

Deutz

Manifold air preheater

KU

Kubota

Engine block heater

FO

Ford

Engine block heater

GM

GM

Radiator Hose In-Line

Figure 8.1 – Engine Manufacturer/Start System

Refer to the engine manufacturer below for specific cold

weather start-up information for that particular engine

type and cold weather start system.

Cummins, Kubota and Ford – Block Heater

Plug the heater cord into a 125 Volt AC, 600 watt source

eight hours before starting the engine. The heater will

warm the engine block to make cold weather starting

easier.

Unplug the power cord before starting the engine.

Cummins – Ether Injection

Some Cummins engines may have an ether injection

system instead of a block heater. Ether injection should

only be used to start a cold engine when the ambient

temperature is below 32°F (0°C).

Make sure there is a can of ether installed in the holder,

in the engine compartment on the right side of the ma-

chine. Use the following procedure to install a can of

ether as necessary.

1. Place the battery disconnect switch in the off posi-

tion.

2. Unscrew the holding cup.

3. Place a new can of ether in the cup.

4. Screw the holding cup firmly into position.