Lanyard anchors, Operating controls, Emergency stop – Snorkel TB50 User Manual

Page 44: Emergency power, Danger, Warning

Chapter 7 – Prestart Inspection

40

TB42/TB50 – 0074923

3. Visually inspect all bolts and nuts fastening the

platform in place. They must be present and not

show any signs of looseness.

4. Inspect the gate(s) to be sure they are present, are

not damaged, and move freely.

Lanyard Anchors

There are two lanyard anchors below the upper control

panel (refer to Figure 7.22).

To inspect the lanyard anchors:

1. Visually inspect the lanyard anchors to make sure

they are in place and are not deformed.

2. Look for visible cracks in the welds and at the weld

to parent material joints. A bright light may be used to

provide adequate visibility of the inspection area.

Operating Controls

Use the following procedure to operate and test the

machine from the upper controls:

1. Turn the battery disconnect switch on.

2. At the lower controls, place the emergency stop

switch and the start switch in the on position. Place

the control selector switch in the upper control posi-

tion.

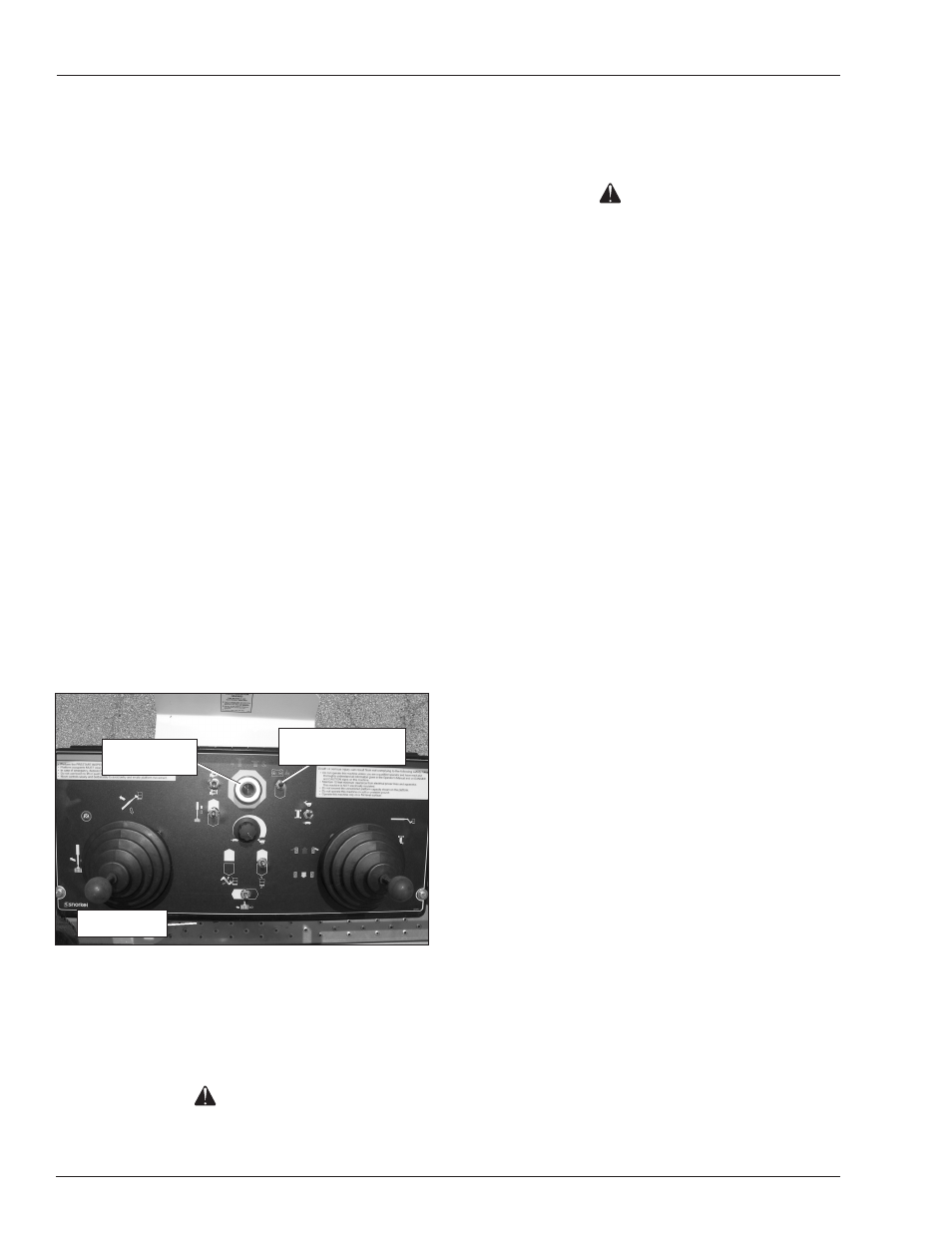

3. At the upper controls (refer to Figure 7.23), pull the

emergency stop button outward.

Figure 7.23 – Upper Controls

4. Turn the start switch on the front of the upper control

panel to start until the engine starts, then release

it.

5. Let the engine warm to operating temperature.

Danger

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures,

or other obstacles. Make sure all personnel stand

clear of the aerial platform while performing the

prestart inspection.

Warning

The potential for an accident increases when operat-

ing an aerial platform that is damaged or malfunction-

ing. Death or serious injury could result from such

accidents. Do not operate the aerial platform if it is

damaged or malfunctioning.

6. Test the platform foot switch by moving a boom

function control without stepping on the foot switch.

If movement occurs the interlock is not function-

ing properly. Do not operate the machine until the

problem is corrected.

7. Test the operation of each control in both directions

from the upper controls.

8. The drive range switch and maximum travel speeds

are interlocked through limit switches on the turn-

table that senses the position of the main boom.

When the main boom is raised approximately

1½″ (3.8 cm) or extended approximately

1″ (2.5 cm), the machine should travel in low

speed only.

To operate in high speed the booms must be

stowed.

Emergency Stop

To test the emergency stop button from the upper

controls:

1. At the lower controls, start the engine and place the

control selector switch in the upper control position.

2. At the upper controls, push the emergency stop but-

ton (refer to Figure 7.22) inward to turn off electrical

power.

3. Verify that the engine shuts off and the upper control

functions do not operate.

Emergency Power

To test the emergency power system from the upper

controls:

1. Turn the battery disconnect switch on.

2. At the lower controls, pull the emergency stop button

outward and place the start switch in the on position.

Place the control selector switch in the upper control

position.

3. At the upper controls (refer to Figure 7.22), pull the

emergency stop button outward and place the start

switch in the on position.

Emergency

Stop Button

Engine/Emergency

Power Switch

Start Switch