Troubleshooting – Fluid Management Miller GyroMixer User Manual

Page 22

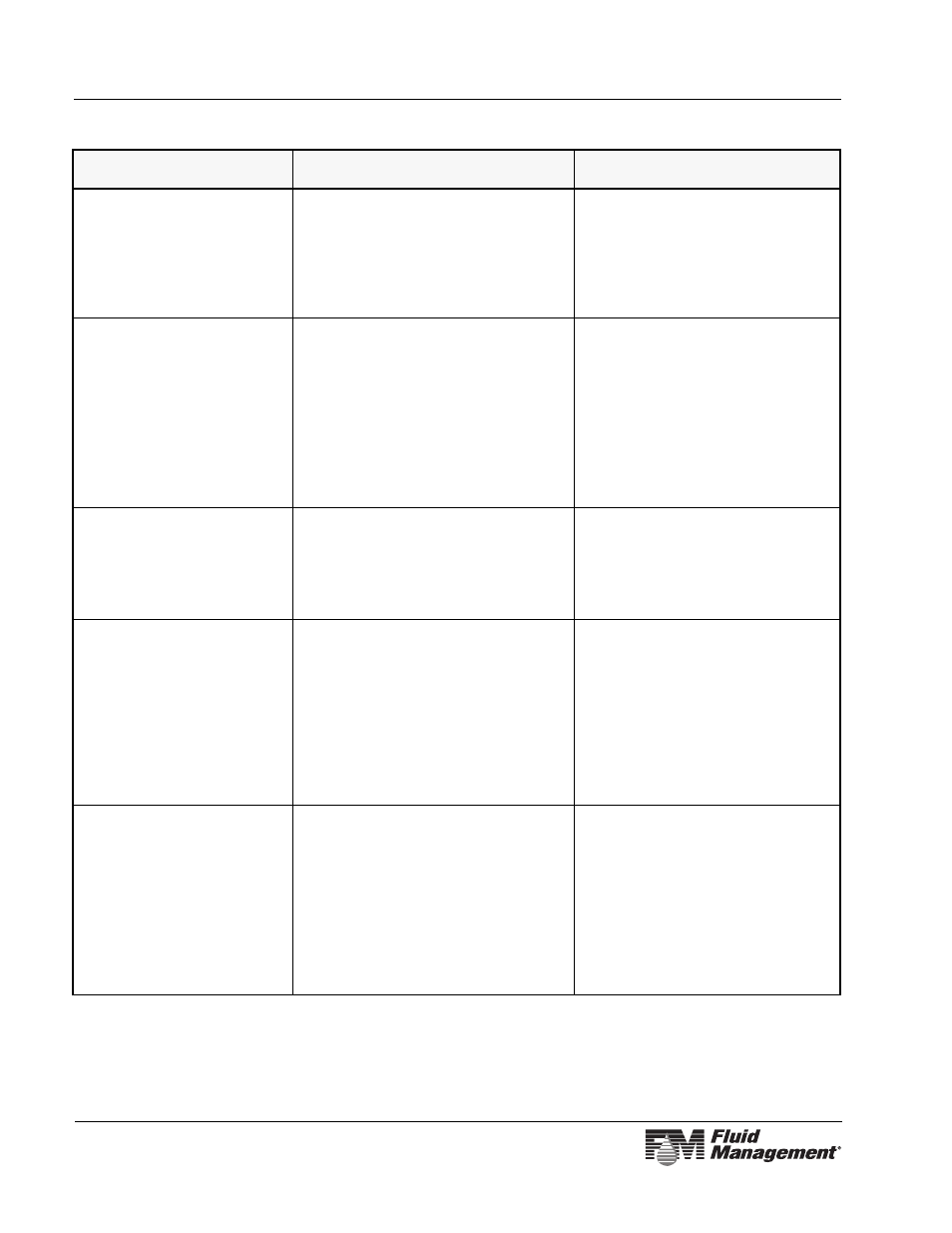

TROUBLESHOOTING

18

Mixer operates, but does not

mix.

Belts loose or defective.

•

Check the poly V-belt and the V-belt.

Replace if necessary.

Improper timer setting.

•

Extend mixing setting. Smaller

containers and heavier viscosities

require extended mixing times.

Mixer operates, but is noisy.

Container not securely clamped in.

•

Check container. Reposition and

clamp securely if necessary.

Bail is not retained.

•

Retail bail.

Belt has fallen off.

•

Check belt. Reposition if necessary.

Binding occurring when rotating clamping

assembly.

•

Replace flange bearing in clamping

assembly.

Mixer operates, but vibrates

excessively or “walks”.

Mixer is not level.

•

Verify if mixer is level. Level if

necessary.

Container is not centered.

•

Center the pail on the table and

reclamp into position.

Mixer operates and timer cycles

completely, but does not mix

thoroughly.

Improper timer setting.

•

Extend mixing setting. Smaller

containers and heavier viscosities

require extended mixing times.

Incorrect drive belt tension.

•

Inspect and adjust drive belt tension

if necessary.

Secondary belt broken.

•

Check secondary belt and replace if

necessary.

Motor runs erratically.

Frayed or loose motor wire.

•

Tighten loose wire or replace

damage wire.

Thermal overload relay defective.

•

Replace motor.

Motor bearings bad.

•

Replace motor.

Primary belt has fallen off.

•

Check primary drive belt. Reposition

or replace, if necessary.

PROBLEM

POSSIBLE CAUSE

ACTION