Table 6-1: typical torque values chart, Warning – Hale RSD User Manual

Page 69

69

Section 6: Corrective Maintenance

Hale Products, Inc., Nov.2005, Rev.-A

Co rr ec tive M ain te n an ce

❑

Gearbox - Apply a coating of Loctite #246 High Temperature Remov-

able Threadlock (or equivalent) to all bolts on the gearbox before

installing.

Hale Series Pump - Apply a coating of Loctite #242 Medium Strength

Threadlock (or equivalent) to all bolts on the Pump before installing.

9.

Before installing the mechanical seal, use alcohol swabs provided by

Hale Products Inc. to clean all grease or oil from the pump shaft and

mechanical seal running faces.

When installing the mechanical seal, apply a generous coating of Pac-

Ease Rubber Lubricant Emulsion (or equivalent) on the rubber seal

parts to ease installation.

WARNING !

DO NOT TOUCH THE CARBON SEAL WHILE INSTALLING THE MECHANICAL

SEAL. USE OF ANY OTHER LUBRICANT CAN DAMAGE THE MECHANICAL

SEAL AND SEAT.

10.

Use a pusher tool or a bearing installation tool when installing bearings

and seals to avoid cocking the bearings or marking the bearing faces.

Also review heading “Bearings” on page 71.

11.

Before placing the apparatus into operation, the pump assembly must

be tested and checked for leaks. All leaks must be repaired

immediately.

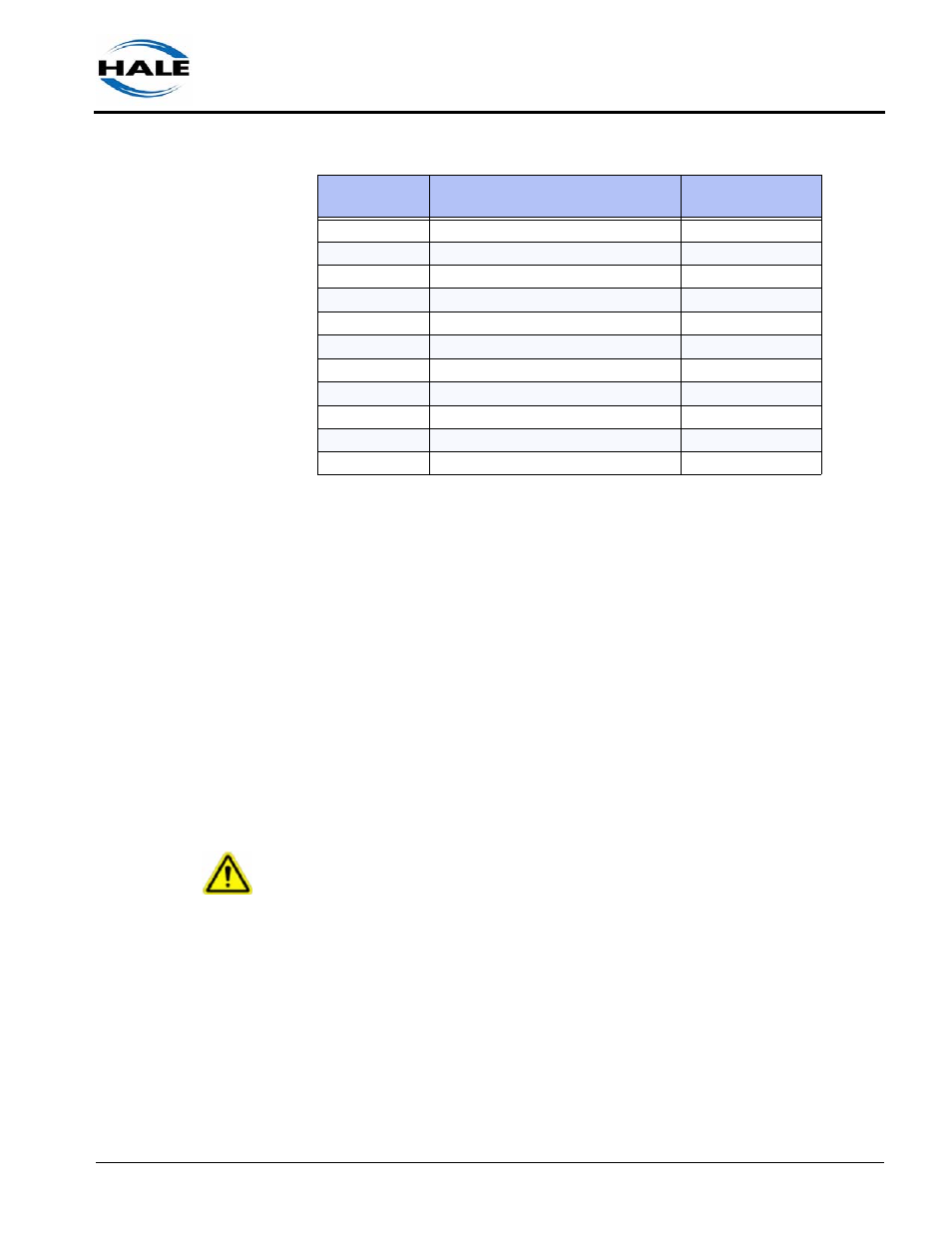

Bolt Size

Lock Nut size

Material

Minimum Torque

Ft.-Lb. (N-m)

5/16”18

Zinc-plated steel

17 (23)

5/16”18

Zinc-plated steel, with 360° nylon lock

19 (26)

5/16”18

Silicon bronze

10.3 (14)

3/8”16

Zinc-plated steel

30 (41)

3/8”16

Zinc-plated steel, with 360° nylon local

33 (45)

3/8”16

Silicon bronze

18 (24)

7/16”14

Zinc-plated steel

50 (68)

7/16”14

Zinc-plated steel, with 360° nylon local

53 (72)

7/16”14

Silicon bronze

29 (39)

5/8”-11

Zinc-plated steel

150 (203)

5/8”-11

Silicon bronze

85 (115)

Table 6-1: Typical Torque Values Chart