Insufficient pump capacity – Hale RSD User Manual

Page 61

61

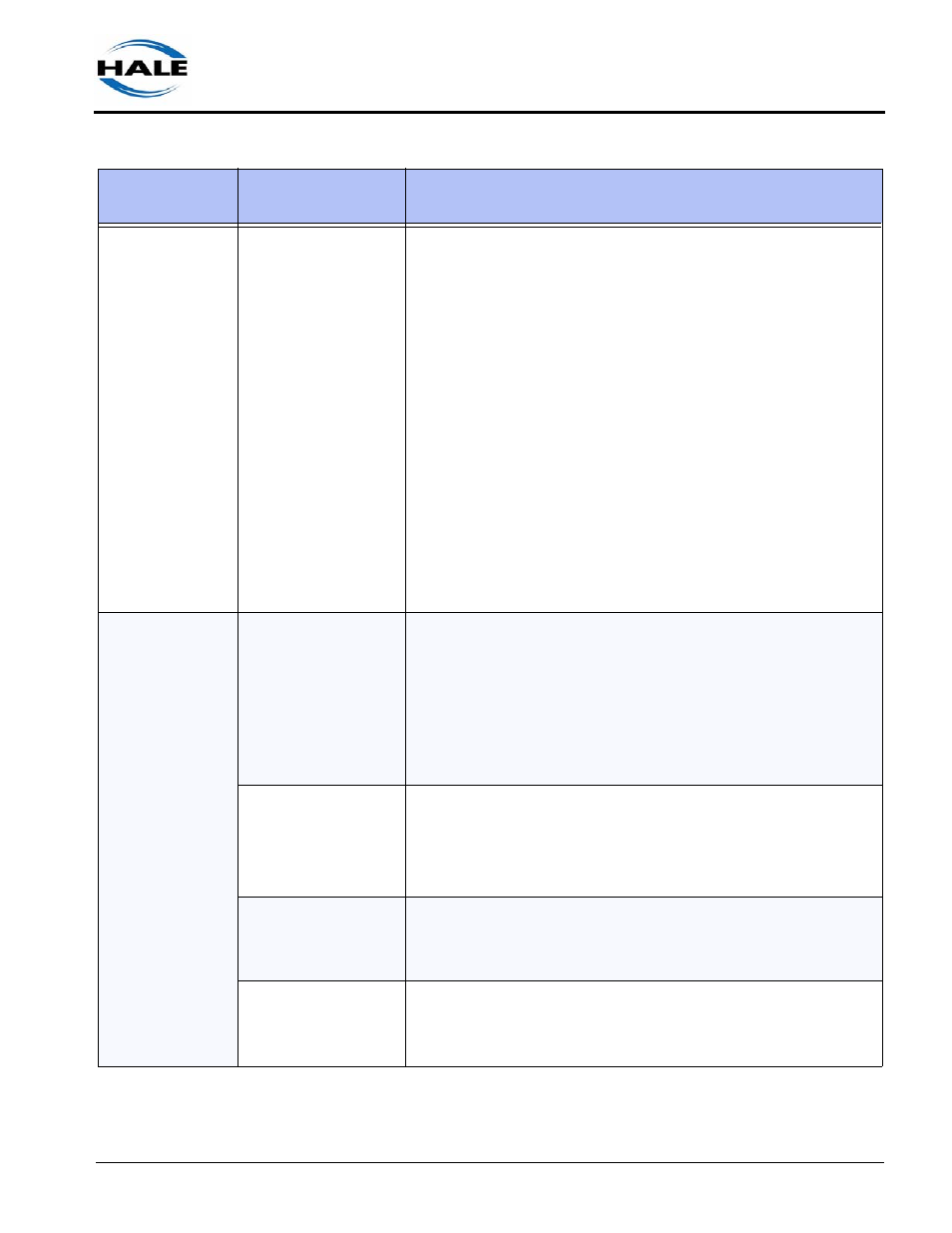

Troubleshooting

Hale Series Pumps, Nov.-05, Rev-A

T r ou b les h oo tin g

❑

Pump Loses Prime

or Will Not Prime -

continued.

Air leaks.

• Attempt to located and correct air leaks using the following

procedures:

• Perform “Dry Vacuum Test” on pump per NFPA standards with

22” Hg. minimum vacuum required with loss not to exceed 10”

Hg. in five (5) minutes.

• If a minimum of 22” Hg. cannot be achieved, the priming

device or system may be inoperative, or the leak is too big for

the primer to overcome (such as an open valve). The loss of

vacuum indicates leakage and could prevent priming or cause

loss of prime.

• After priming shut OFF the engine. Audible detection of a leak

is often possible.

• Connect the suction hose from the hydrant or the discharge of

another pumper to pressurize the pump with water and look for

visible leakage and correct. A pressure of 100 PSI (6.9 BAR)

should be sufficient. DO NOT exceed pressure limitations of

pump, accessories or piping connections.

• The suction side relief valve can leak. Plug the valve outlet

connection and retest

Insufficient

Pump Capacity.

Chart continued on

next page.

Insufficient engine

power.

• Engine power check and tune up may be required for peak engine

and pump performance.

• Also see Section “Rotation Symptoms.” on page 65.

• Recheck pumping procedure for recommended transmission gear

or range. Use mechanical speed counter on pump panel to check

actual speed against possible clutch or transmission slippage or

inaccurate tachometer.

• Check truck manual for proper speed counter ratio.

Relief valve improp-

erly set - if so

equipped.

• If relief valve pressure is set too low it allows the valve to open

and bypass water.

• Reset the relief valve pressure accordingly.

• Also see Section 4 Preventive Maintenance, heading “Relief Valve

Suction hose diame-

ter is too small for the

volume being dis-

charged.

• Use larger suction hose.

• Shorten total length by remove one length at a time.

• Reduce volume of discharge.

Restriction in suction

line at strainer.

• Remove any debris restricting entrance of water at the strainer.

• Also see Section 4 Preventive Maintenance, heading “Intake

Condition

Possible

Cause

Suggested Corrective Action

Figure 5-2: Troubleshooting Chart