Hale RSD User Manual

Page 60

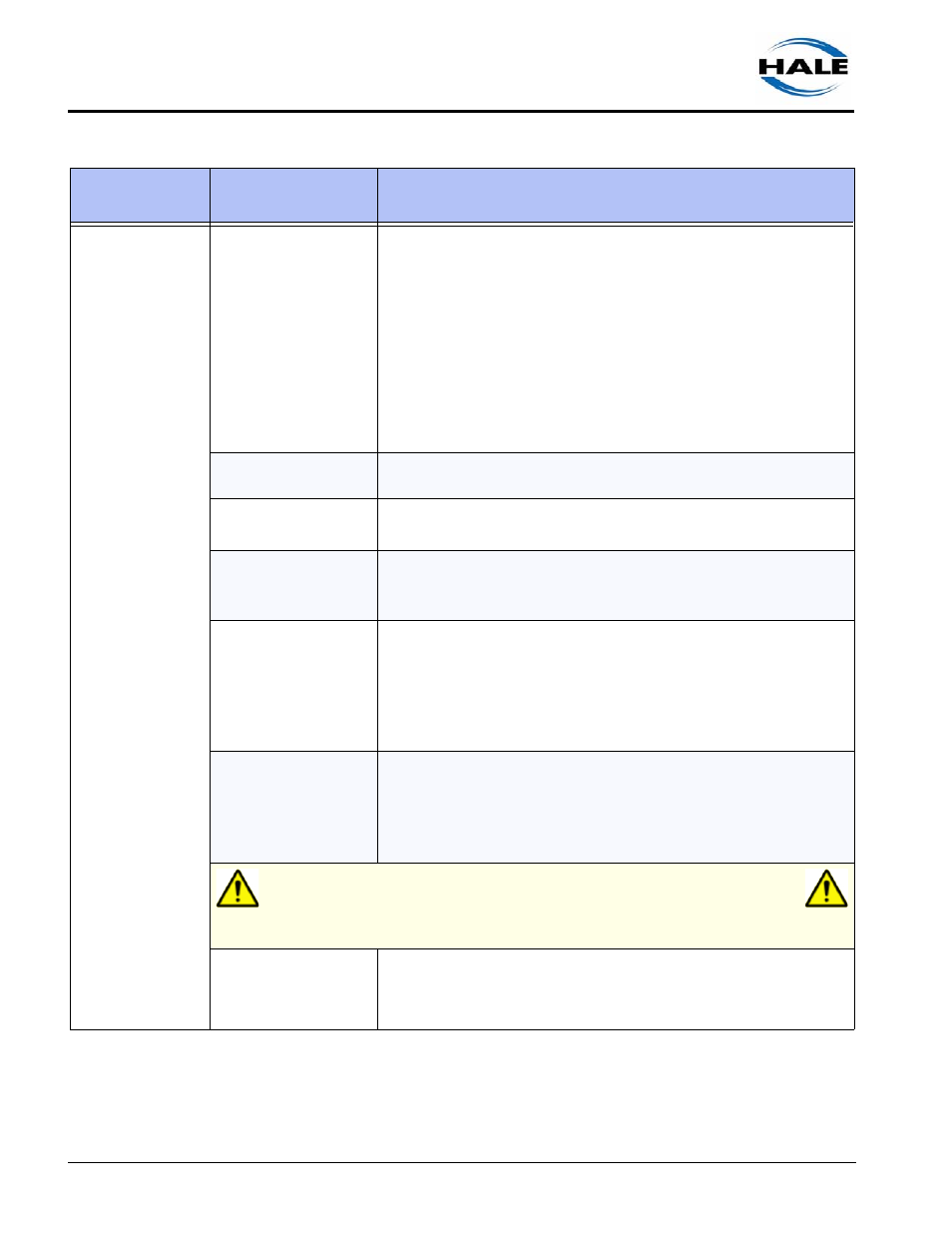

❑ Troubleshooting

60

Troubleshooting

Hale Series Pumps, Nov.-05, Rev-A

Pump Loses Prime

or Will Not Prime -

continued.

Chart continued on

next page.

Inoperative priming

system or possible

clogged priming pump

- continued.

• Check the priming system by performing a “Dry Vacuum Test” per

NFPA standards. If the pump holds vacuum, but primer pulls less

than 22” Hg., it could indicate excessive wear in the primmer.

• See Section 4 Preventive Maintenance, heading “Weekly” on

page 46. Also see Section 4 Preventive Maintenance, heading

“Annual” on page 52.

• See Section 2a, heading “Priming Valves” on page 25.

• Repair and/or replace accordingly.

Note: Using lubricant on the vanes and vane slots during disassembly and

cleaning eventually causes a gummy residue to develop, rendering the sys-

tem inoperative.

Suction lifts too high.

• DO NOT attempt lifts exceeding 22’ (6.7 meters) except at low

elevation.

Blocked or restricted

suction strainer.

• Remove obstruction from suction hose strainer.

• Thoroughly clean strainer screen.

Suction connections.

• Clean and tighten all suction connections.

• Check suction hose and hose gaskets for possible defects - repair

and/or replace.

Air trapped in suction

line.

• Avoid placing any part of the suction hose higher than the suction

intake.

• Suction hose should be laid out with continuos decline to fluid

supply.

• If trap in hose in unavoidable, repeated priming may be needed to

eliminate air pockets in suction hose.

Insufficient priming.

• Proper priming procedures should be followed.

• Do not release the primer control before assuring a complete

prime.

• Open the discharge valve slowly during completion of prime to

ensure complete prime.

NOTICE !

DO NOT RUN THE PRIMER OVER FORTH-FIVE (45) SECONDS. IF PRIME IS

NOT ACHIEVED WITHIN 45 SECONDS, STOP AND LOOK FOR CAUSES

(AIR LEAKS OR BLOCKED SUCTION HOSES).

Pump pressure too

low when nozzle is

opened.

• Prime pump again and maintain higher pump pressure while

opening the discharge valve slowly.

Condition

Possible

Cause

Suggested Corrective Action

Figure 5-2: Troubleshooting Chart