2 introduction, 1 principles of operation, Centrifugal force – Hale RSD User Manual

Page 15: Figure 2-1: centrifugal force - rotating disk, Introduction, Principles of operation, 2introduction

15

Section 2: Introduction

Hale Products, Inc., Nov. 2005, Rev-A

In tro d u ctio n

❑

2

Introduction

2.1

PRINCIPLES OF OPERATION

Centrifugal Force

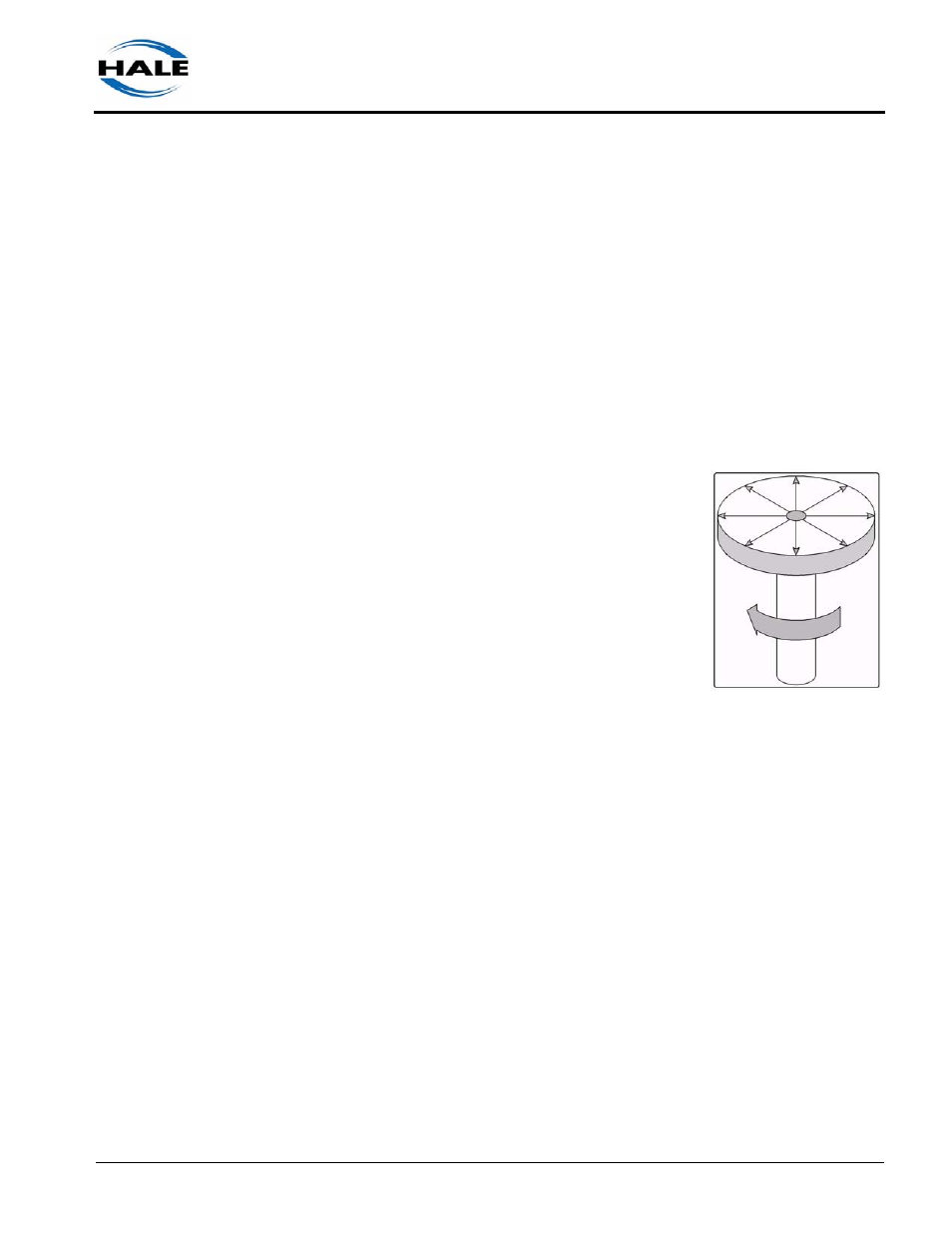

Hale pumps are centrifugal pumps that operate on the principle of centrifu-

gal force created by a rapidly spinning disk. (See Figure 2-1: “Centrifugal

Force - Rotating Disk.”)

As the disk rotates, it throws water from the center

toward the outer circumference of the disk. The

velocity at which the water travels from the center

directly relates to the diameter of the disk and the

speed of rotation.

When water is confined in a closed container, such

as the volute (pump body), the velocity of the water

is converted to pressure that rises to a level depen-

dent on the speed of rotation.

There are three interrelated factors that regulate

the performance of a centrifugal pump:

❑

SPEED (RPM) If the speed of rotation

increases with flow held constant, fluid pressure increases.

❑

PRESSURE If pressure changes with speed held constant, the flow,

measured in gallons or liters per minute (GPM/LPM), changes inversely;

if pressure increases, flow decreases. Pressure is measured in pounds

per square inch (PSI) or BAR.

❑

FLOW If the pressure is held constant, the flow increases with an

increase in the speed of rotation. Flow is measured in the number of gal-

lons of fluid per minute (GPM/LPM) that a pump can deliver when sup-

plied from draft.

A centrifugal pump is preferred by the fire protection service due to its ability

to fully utilize any positive suction inlet pressure, reducing the amount of

work done by the pump.

For example, if the required discharge pressure is 120 PSI (8.3 BAR) and

the inlet pressure is 45 PSI (3.1 BAR), the pump must only produce the dif-

ference in pressure or 75 PSI (5.2 BAR).

Figure 2-1: Centrifugal

Force - Rotating Disk