Bryant F User Manual

Page 41

41

The enthalpy control receives the outdoor air enthalpy

from the outdoor air enthalpy sensor and provides a dry

contact switch input to the RTU--MP controller. A closed

contact indicates that outside air is preferred to the return

air. An open contact indicates that the economizer should

remain at minimum position.

Differential Enthalpy Control

Differential enthalpy control is provided by sensing and

comparing the outside air and return air enthalpy

conditions. Install the outdoor air enthalpy control as

described above. Add and install a return air enthalpy

sensor.

Return Air Enthalpy Sensor

Mount the return--air enthalpy sensor (HH57AC078) in the

return--air duct. The return air sensor is wired to the

enthalpy controller (HH57AC077). (See Fig. 51.)

LED

A

B

C

D

TR

TR1

SO

SR

2

3

1

+

+

BRN

RED

GRAY/ORN

GRAY/RED

WIRE HARNESS

IN UNIT

BLK

RED

S

+

(RETURN AIR

ENTHALPY

SENSOR)

S

+

(OUTDOOR

AIR

ENTHALPY

SENSOR)

ENTHALPY CONTROLLER

NOTES:

1. Remove factory-installed jumper across SR and + before connecting

wires from return air sensor.

2. Switches shown in high outdoor air enthalpy state. Terminals 2 and 3

close on low outdoor air enthalpy relative to indoor air enthalpy.

3. Remove sensor mounted on back of control and locate in outside air-

stream.

C06019

Fig. 51 -- Outside and Return Air Enthalpy

Sensor Wiring

To wire the return air enthalpy sensor, perform the

following:

1. Use a 2--conductor, 18 or 20 AWG, twisted pair cable

to connect the return air enthalpy sensor to the

enthalpy controller.

2. At the enthalpy control remove the factory--installed

resistor from the (SR) and (+) terminals.

3. Connect the field--supplied RED wire to (+) spade

connector on the return air enthalpy sensor and the

(SR+) terminal on the enthalpy controller. Connect

the BLK wire to (S) spade connector on the return air

enthalpy sensor and the (SR) terminal on the enthalpy

controller.

NOTE: The enthalpy control must be set to the “D”

setting for differential enthalpy control to work properly.

The enthalpy control receives the indoor and return

enthalpy from the outdoor and return air enthalpy sensors

and provides a dry contact switch input to the RTU--MP

controller. A closed contact indicates that outside air is

preferred to the return air. An open contact indicates that

the economizer should remain at minimum position.

Indoor Air Quality (CO

2

Sensor)

The indoor air quality sensor accessory monitors space

carbon dioxide (CO

2

) levels. This information is used to

monitor IAQ levels. Several types of sensors are available,

for wall mounting in the space or in return duct, with and

without LCD display, and in combination with space

temperature sensors. Sensors use infrared technology to

measure the levels of CO

2

present in the space air.

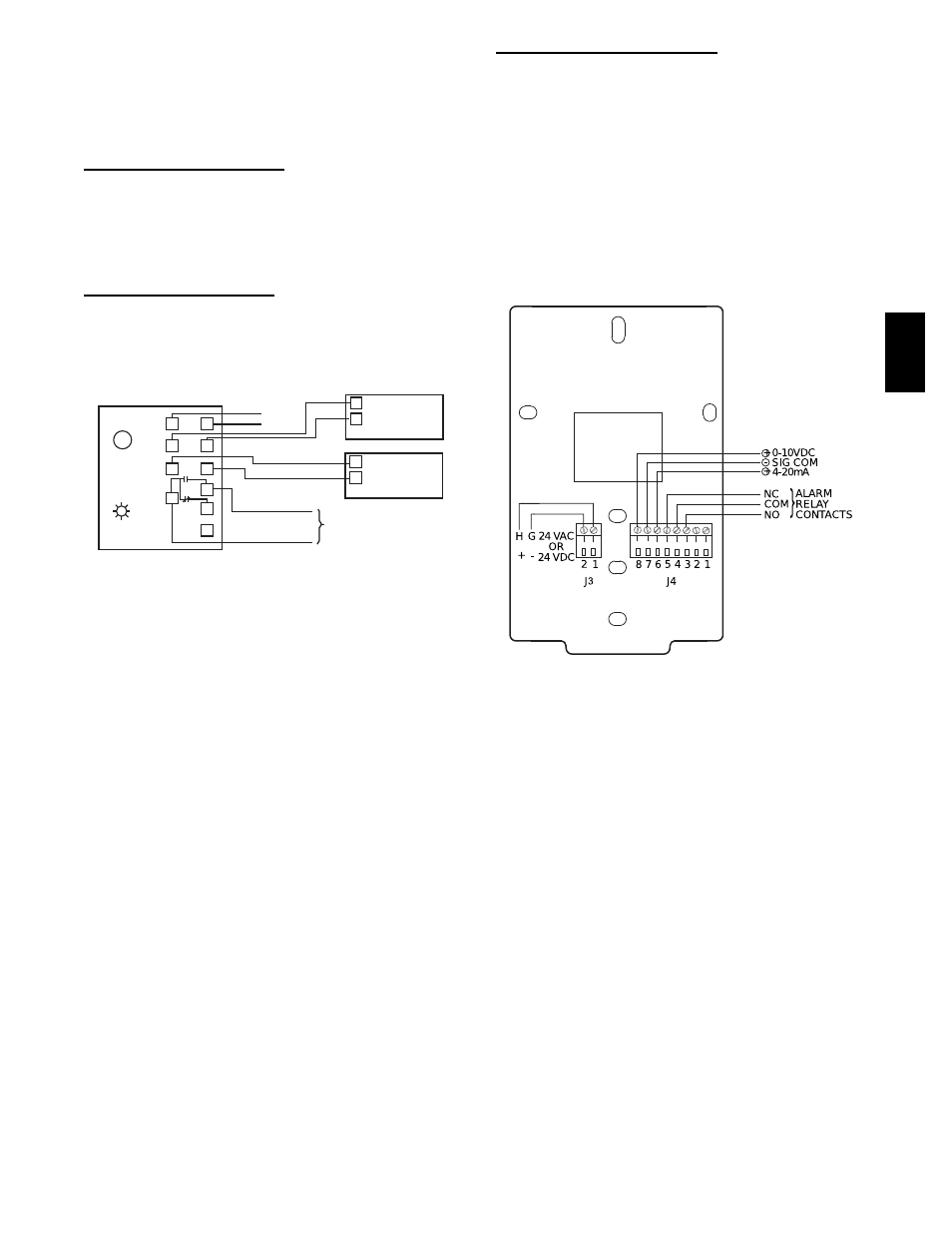

The CO

2

sensors are all factory set for a range of 0 to

2000 ppm and a linear mA output of 4 to 20. Refer to the

instructions supplied with the CO

2

sensor for electrical

requirements and terminal locations. See Fig. 52 for

typical CO

2

sensor wiring schematic.

C07134

Fig. 52 -- Indoor/Outdoor Air Quality (CO

2

) Sensor

(33ZCSENCO2) -- Typical Wiring Diagram

To accurately monitor the quality of the air in the

conditioned air space, locate the sensor near a return--air

grille (if present) so it senses the concentration of CO

2

leaving the space. The sensor should be mounted in a

location to avoid direct breath contact.

Do not mount the IAQ sensor in drafty areas such as near

supply ducts, open windows, fans, or over heat sources.

Allow at least 3 ft (0.9 m) between the sensor and any

corner. Avoid mounting the sensor where it is influenced

by the supply air; the sensor gives inaccurate readings if

the supply air is blown directly onto the sensor or if the

supply air does not have a chance to mix with the room air

before it is drawn into the return airstream.

Wiring the Indoor Air Quality Sensor

For each sensor, use two 2--conductor 18 AWG (American

Wire Gauge) twisted--pair cables (unshielded) to connect

the separate isolated 24 vac power source to the sensor

and to connect the sensor to the control board terminals.

580J