Bryant 551C User Manual

Page 28

28

C06034

Fig. 33

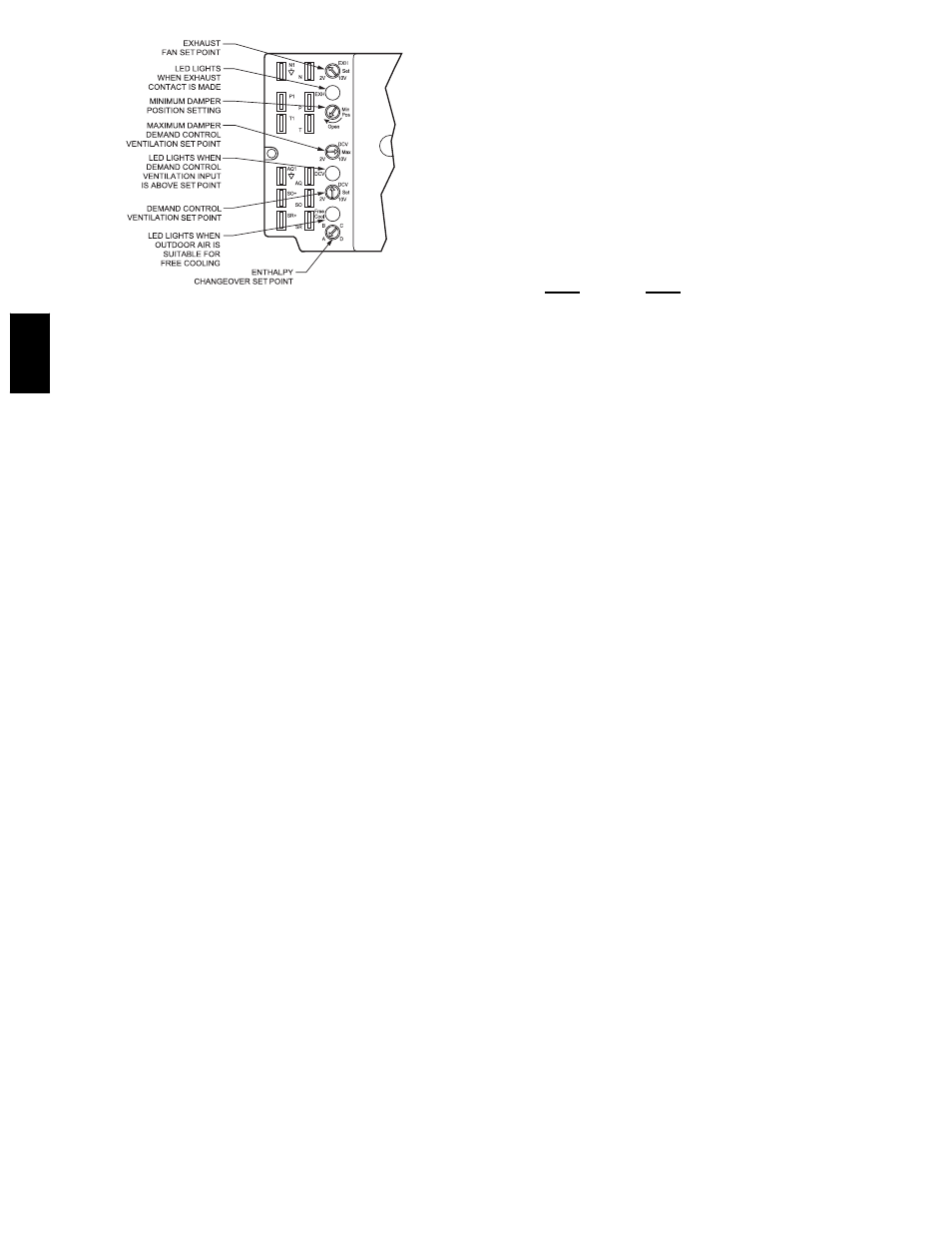

--- EconoMi$er IV Controller Potentiometer

and LED Locations

Replace the standard outside air dry bulb temperature sensor with

the accessory enthalpy sensor in the same mounting location.

(See Fig. 21.) Mount the return air enthalpy sensor in the return

air duct. (See Fig. 35.) Wiring is provided in the EconoMi$er IV

wiring harness. (See Fig. 27.) The outdoor enthalpy changeover

set point is set with the outdoor enthalpy set point potentiometer

on the EconoMi$er IV controller. When using this mode of

changeover control, turn the enthalpy setpoint potentiometer fully

clockwise to the D setting.

Indoor Air Quality (IAQ) Sensor Input

The IAQ input can be used for demand control ventilation control

based on the level of CO

2

measured in the space or return air

duct.

Mount the accessory IAQ sensor according to manufacturer

specifications. The IAQ sensor is wired to the AQ and AQ1

terminals of the controller. Adjust the DCV potentiometers to

correspond to the DCV voltage output of the indoor air quality

sensor at the user-determined set point. (See Fig. 38.)

If a separate field-supplied transformer is used to power the IAQ

sensor, the sensor must not be grounded or the EconoMi$er IV

control board will be damaged.

Exhaust Set Point Adjustment

The exhaust set point will determine when the exhaust fan runs

based on damper position (if accessory power exhaust is

installed). The set point is modified with the Exhaust Fan Set

Point (EXH SET) potentiometer. (See Fig. 33.) The set point

represents the damper position above which the exhaust fans will

be turned on. When there is a call for exhaust, the EconoMi$er IV

controller provides a 45 ± 15 second delay before exhaust fan

activation to allow the dampers to open. This delay allows the

damper to reach the appropriate position to avoid unnecessary fan

overload.

Minimum Position Control

There is a minimum damper position potentiometer on the

EconoMi$er IV controller. (See Fig. 33.) The minimum damper

position maintains the minimum airflow into the building during

the occupied period.

When using demand ventilation, the minimum damper position

represents the minimum ventilation position for VOC (volatile

organic compound) ventilation requirements. The maximum

demand ventilation position is used for fully occupied ventilation.

When demand ventilation control is not being used, the minimum

position potentiometer should be used to set the occupied

ventilation position. The maximum demand ventilation position

should be turned fully clockwise.

Adjust the minimum position potentiometer to allow the

minimum amount of outdoor air, as required by local codes, to

enter the building. Make minimum position adjustments with at

least 10_F temperature difference between the outdoor and

return-air temperatures.

To determine the minimum position setting, perform the

following procedure:

1. Calculate the appropriate mixed air temperature using the

following formula:

(T

OA

) + (TR

x

RA

) T

(T

O x

100 )

+ (TR

x

100 ) =T

M

T

O

= Outdoor-Air Temperature

OA = Percent of Outdoor Air

T

R

= Return-Air Temperature

RA = Percent of Return Air

T

M

= Mixed-Air Temperature

As an example, if local codes require 10% outdoor air during

occupied conditions, outdoor-air temperature is 60_F, and

return-air temperature is 75_F.

(60 x .10) + (75 x .90) = 73.5_F

2. Disconnect the supply air sensor from terminals T and T1.

3. Ensure that the factory-installed jumper is in place across

terminals P and P1. If remote damper positioning is being

used, make sure that the terminals are wired according to

Fig. 27 and that the minimum position potentiometer is

turned fully clockwise.

4. Connect 24 vac across terminals TR and TR1.

5. Carefully adjust the minimum position potentiometer

until the measured supply air temperature matches the

calculated value.

6. Reconnect the mixed air sensor to terminals T and T1.

Remote control of the EconoMi$er IV damper is desirable when

requiring

additional

temporary

ventilation.

If

a

field-supplied remote potentiometer (Honeywell part number

S963B1128) is wired to the EconoMi$er IV controller, the

minimum position of the damper can be controlled from a remote

location.

To control the minimum damper position remotely, remove the

factory-installed jumper on the P and P1 terminals on the

EconoMi$er IV controller. Wire the field-supplied potentiometer

to the P and P1 terminals on the EconoMi$er IV controller. (See

Fig. 37.)

Damper Movement

Damper movement from full open to full closed (or vice versa)

takes 2

1

/

2

minutes.

Thermostats

The EconoMi$er IV control works with conventional thermostats

that have a Y1 (cool stage 1), Y2 (cool stage 2), W1 (heat stage

1), W2 (heat stage 2), and G (fan). The EconoMi$er IV control

does not support space temperature sensors. Connections are

made at the thermostat terminal connection board located in the

main control box.

551B

,C