4 sampling point, 5 performing a com bus tion test – Bacharach Fyrite INSIGHT User Manual

Page 14

Instruction 24-9460

22

Fyrite

®

INSIGHT

Instruction 24-9460

23

Fyrite

®

INSIGHT

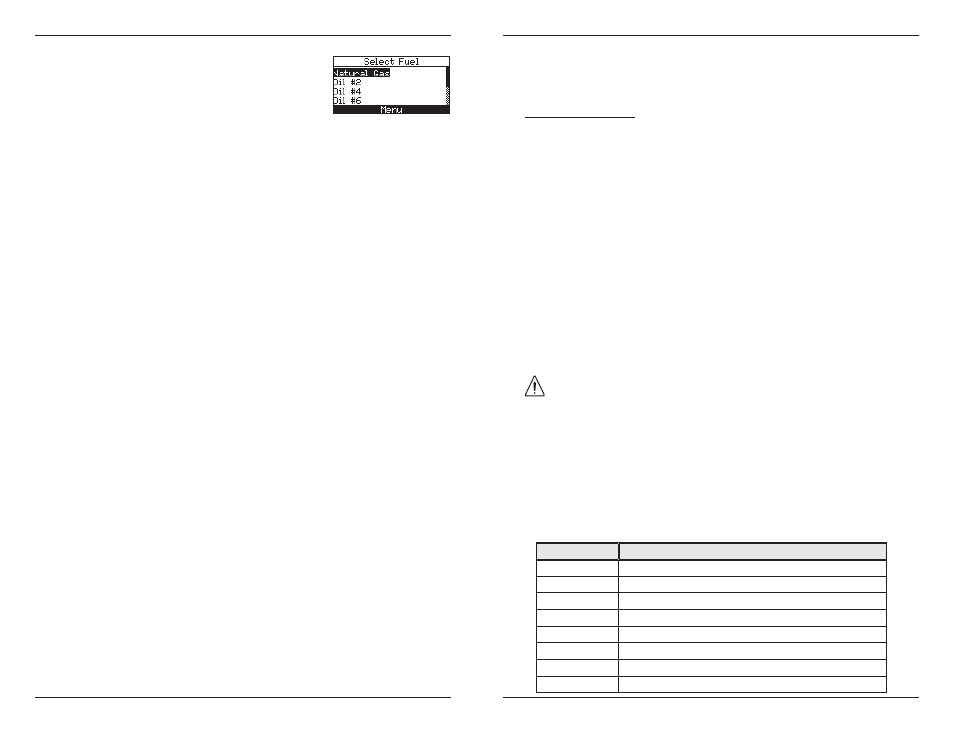

4. Press ENTER to save the selection and re-

turn to the Combustion Test HOLD screen

or ESC to revert to the previous setting and

return to the MAIN MENU.

4.4 Sampling Point

Forced Air Furnace – When testing atmospheric burner or gravity

vented, forced air heating equip ment with a clamshell or sectional heat

exchanger design, test each of the exhaust ports at the top of the heat ex-

changer. The probe should be inserted back into each of the exhaust ports

to obtain a flue gas sample, before any dilution air is mixed in.

Hot Water Tank – Domestic hot water tanks with the ‘bell’ shaped draft

diverter on top can be accurately tested by inserting the probe tip directly

into the top of the fire tube be low the diverter.

80% Efficiency Fan Assist or Power Vented – Combustion testing of

fan assist or power vented, furnaces/boilers should be done through a hole

drilled in the vent approximately 12 inches above the inducer fan.

90% Efficiency Condensing – Condensing furnaces/boilers can be tested

through a hole drilled in the plastic vent pipe (when allowed by the manufac-

turer or local authority of jurisdiction) or taken from the exhaust termination.

After testing, the hole should be sealed with high temperature silicon.

Atmospheric or Gravity Vented Boiler – Boilers, which have a ‘bell’

shaped draft diverter directly on top, should be tested directly below the

diverter through a hole drilled in the vent connector.

NOTE: All drill holes should be sealed upon completion of combus-

tion testing.

4.5 Performing a Com bus tion Test

Ensure that the following has been completed, and then proceed with the

combustion test as described below:

• Power ON analyzer and allow it to warm up (Section 4.2).

• Select fuel being burned (Section 4.3).

• Inset probe into proper sample location (Section 4.4).

• If necessary, insert optional primary air thermocouple into combustion-

air stream of burners that use an outside source of combustion air.

1. Press the RUN/HOLD button to start the test. You should hear the

pump start running and see the word RUN appear at the top of the

Combustion Test screen.

Sensor Indicators: The following indicators appear in the sensor's data

field depending on certain conditions:

(

∗ ∗ ∗

) Sensor that is not calibrated or installed.

(XXX) Sensor overrange

(

- - -

) The calculated data cannot be displayed because the measured

data necessary to make the calculation is out of range (i.e., oxygen level

above 16%).

2. Use the up and down arrow keys to scroll to the T-STK reading.

Loosen the thumbscrew on probe stop and move probe in and out of

the stack until the stack’s core temperature (hot spot) is located as

indicated by the highest T-STK reading; then tighten thumbscrew to

prevent further probe movement. Locating the highest stack tempera-

ture is very important for accurate efficiency calculations.

3. You can now begin burner-service procedures. The analyzer readings

will change quickly to show changes in burner performance.

CAUTION:

Position the Water Trap with its gas-flow

arrow pointing upward. Do not let water condensate go above

the tip of the riser tube. The sensors could be damaged if water

would enter the analyzer. Empty the Water Trap after every

combustion test (refer to Section 4.10)

4. Pressing the RUN/HOLD button freezes all readings, stops the pump and

displays the Combustion-Test HOLD screen. Use the ▲▼ buttons to view

all test values at the moment the RUN/HOLD button was pressed. Press-

ing RUN/HOLD again restarts the pump and resumes testing.

Display Name

Description of Measurement or Calculation

O

2

% Oxygen

CO

ppm Carbon Monoxide

Eff

% Combustion Effi ciency

CO

2

% Carbon Dioxide

T-STK

Stack Temperature

T-AIR

Primary/Ambient Air Temperature

EA

% Excess Air

CO(O)

Carbon Monoxide ppm level referenced to a % of oxygen