Howard HI-110 Network Transformer User Manual

Page 26

Document 2.4.128, Revision 2

August, 2012

26

Network Transformer Instruction Manual

tank-mounted components are over tightened. Check

with the Howard Industries Transformer Division

for recommended torque values for any devices or

connections not listed below. Use manufacturer’s

recommended torque values for any user-supplied

devices.

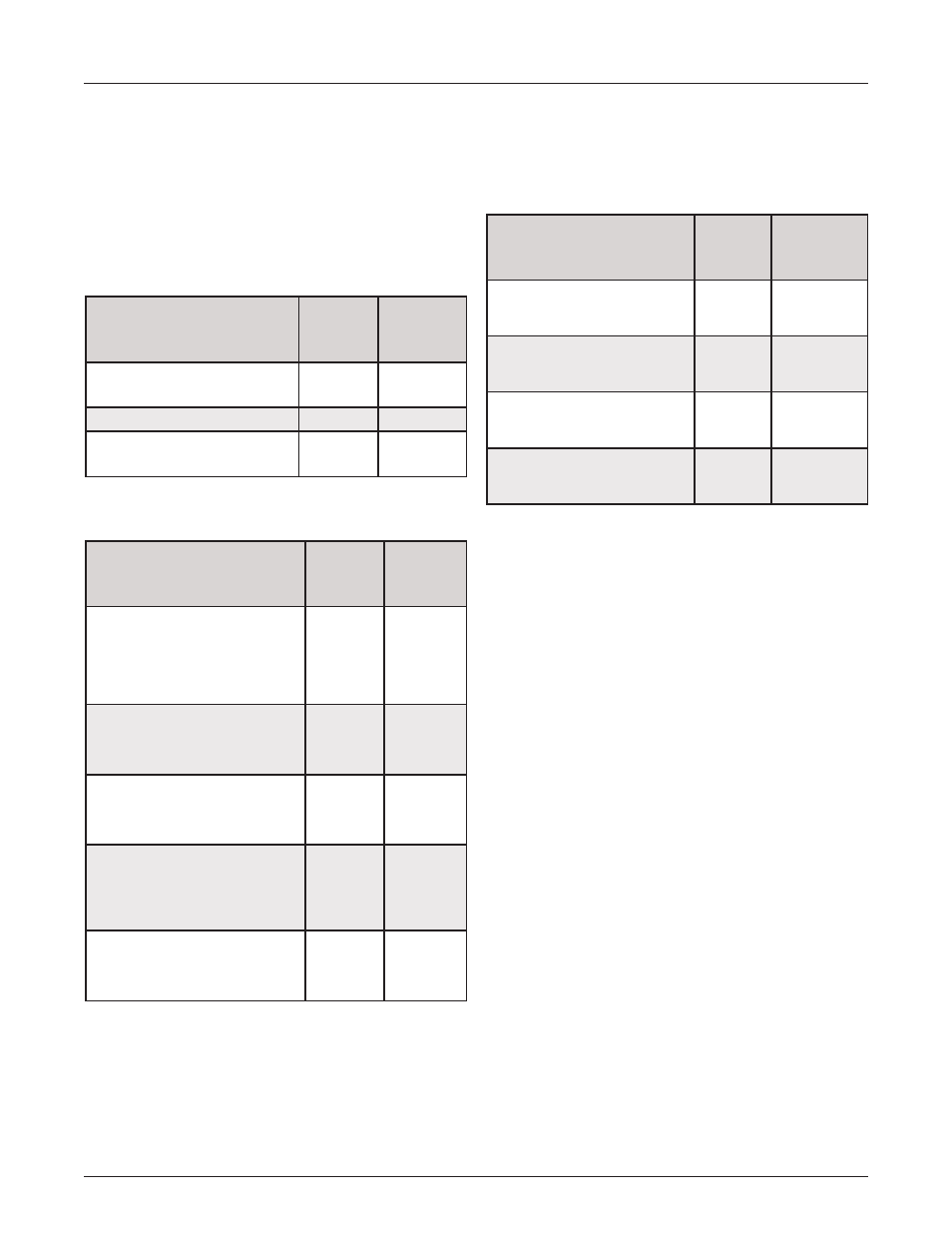

Table 3: Torque Guidelines for External Cabinet

Fasteners

Fastener Type

Nominal

Torque

(in-lbs)

Torque

Range

(in-lbs)

Secondary throat shipping

guard bolts

80

70-90

Hand-hole cover bolts

190

170-210

Terminal and switch cham-

ber cover bolts

350

300-400

Table 4: Torque Guidelines for External Bushing

Mounting Hardware

Bushing Type

Nominal

Torque

¹

(in-lbs)

Torque

Range

Low-voltage bushing,

molded Tri-Clamp

(without clamp ring),

3/8” mounting studs

60

40-80

Low-voltage bushing,

molded (with clamp ring),

3/8” mounting studs

120

90-150

Low-voltage bushing,

porcelain (with clamp ring),

1/2” mounting studs

80

70-90

High-voltage bushing well,

molded Tri-Clamp (without

clamp ring), 3/8” mounting

studs

60

40-80

High-voltage bushing well,

molded (with clamp ring),

3/8” mounting studs

120

90-150

Notes:

¹ When checking tightness of gasketed

components, the measured torque will normally

be less than the nominal torque listed in the table

above due to relaxation of the gasket material.

Additional tightening of bushing mounting

hardware may cause the component to crack or

the gasket to become over-compressed.

Table 5: Torque Guidelines for External Bushing

Terminal Connections

Terminal Type

Nominal

Torque

²

(in-lbs)

Torque

Range (in-

lbs)

High-voltage molded

bushing insert ¹

180

156-204

Low-voltage bushing,

5/8” jam nut

600

480-720

Low-voltage bushing,

1” jam nut

600

480-720

Low-voltage bushing,

1-1/4” jam nut

720

600-840

Notes:

¹ Apply silicone grease before installation according

to the insert manufacturer’s instructions.

² When checking tightness of gasketed

components and molded busing inserts, the

measured torque will normally be less than the

nominal torque listed in the table above due to

relaxation of the gasket material. Additional

tightening of bushing mounting hardware or

bushing insert may cause the component to

crack or the gasket to become over-compressed.