WIKA CPP1600-X User Manual

Page 14

11178035 12/2010 GB/D/F/E

Hand Spindle Pump

CPP1000-M/-L

WIKA Operating Instructions Hand Spindle Pump

14

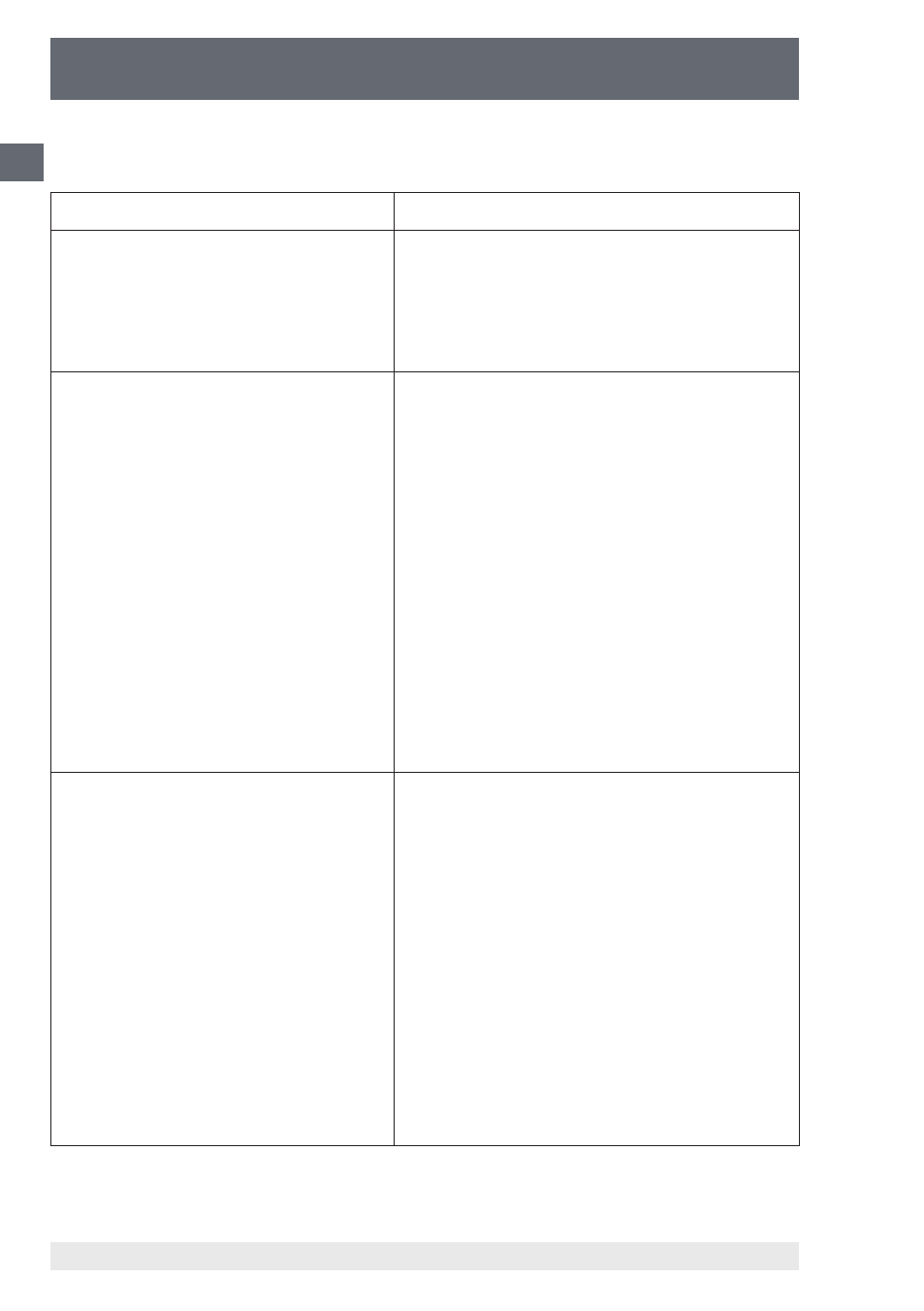

Table: Fault description and measures

Type of fault:

Measures:

I. Unable to build up pressure/leak in

the system

■

Close shut-off valve of the reservoir

correctly

■

Check whether the seals have been

placed in the pressure connections and

whether they are properly positioned.

II. Unable to build up pressure, or

maximum pressure cannot be

reached

■

After the mounting of the test specimen

and the reference instrument, air may be

trapped in the system.

Please note: The system should be vented

before beginning with calibration. For this

purpose, proceed according to chapters

3.1.2 to 3.1.4.

■

Afterwards, build the pressure back up.

NOTE: For calibration cycles with larger

volumes, it is advisable to fill the test speci-

men, and if necessary, the reference instru-

ment with operating liquid beforehand or to

use the shut-off valve for test connection,

which is available as an accessory (see

chapter 9. Accessories).

III. Slow pressure drop

■

Leak in the system, see point I.

■

If small amounts of air are always

compressed in the system together with

the medium, the test pressure that has

been generated first drops off slightly.

After this it must be readjusted.

■

If the system is pressurised quickly, it

takes a certain time (<1 minute) until it can

stabilise thermally. The pressure should

then be adjusted accordingly.

■

After the clamping of the test specimen

and the reference instrument, air may be

trapped in the system, see point II.

■

Afterwards, build the pressure back up.

Further help can be found through WIKA‘s Test & Calibration Technolgy Department.

GB