Maintenance and cleaning – WIKA TR75 User Manual

Page 20

11325232.04 01/2014 GB/D/F/E

20

WIKA operating instructions DiwiTherm

®

, model TR75

GB

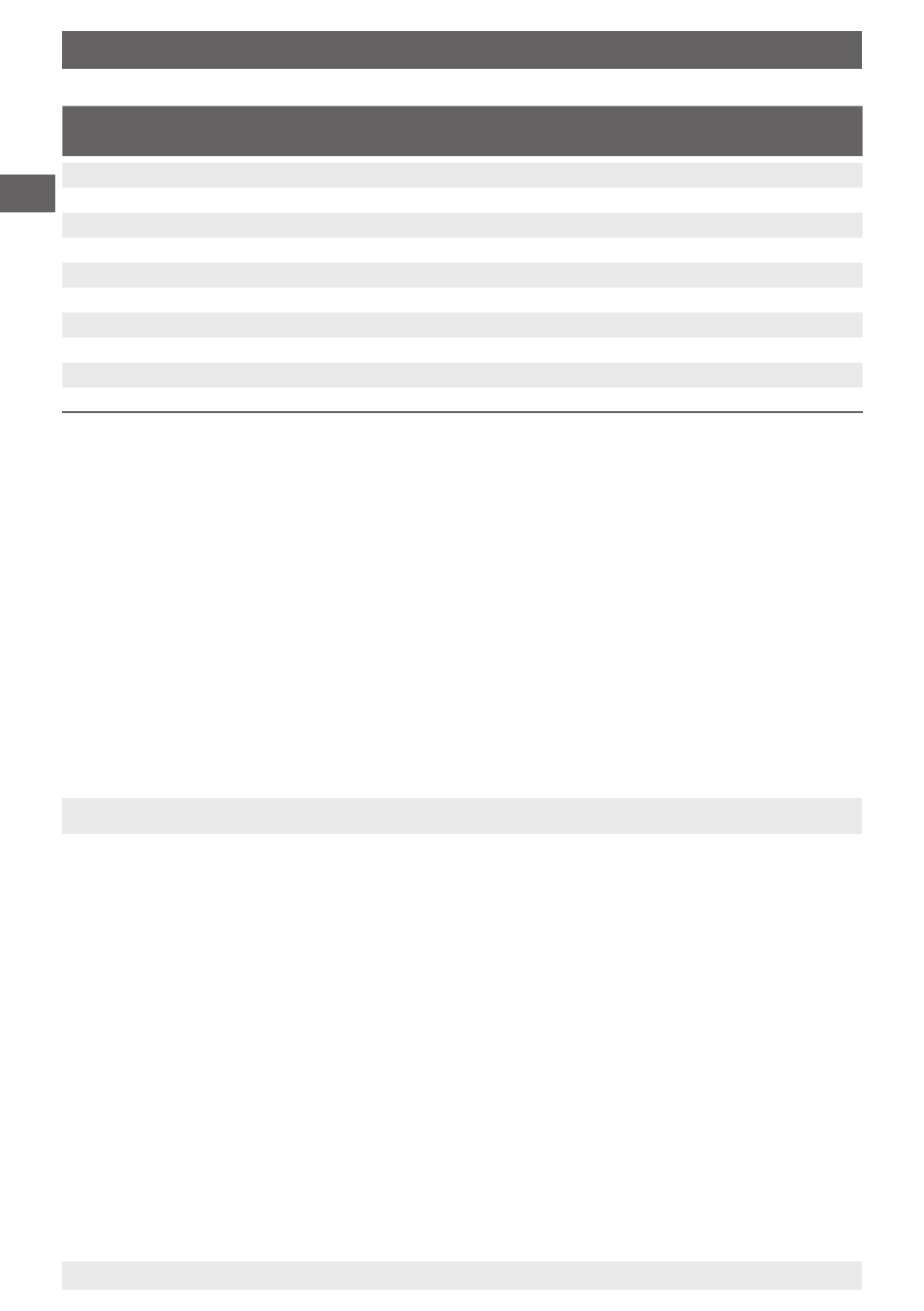

WIKA

Order no.

Designation

Suitable for threads

11349981

per DIN 7603 Form C 14 x 18 x 2 -CuFA

G ¼, M14 x 1.5

11349990

per DIN 7603 Form C 18 x 22 x 2 -CuFA

M18 x 1.5, G ⅜

11350008

per DIN 7603 Form C 21 x 26 x 2 -CuFA

G ½, M20 x 1.5

11350016

per DIN 7603 Form C 27 x 32 x 2.5 -CuFA

G ¾, M27 x 2

11367416

per DIN 7603 Form C 20 x 24 x 2 -CuFA

M20 x 1.5

1248278

per DIN 7603 D21.2 x D25.9 x 1.5 -Al

G ½, M20 x 1.5

3153134

per DIN 7603 Form C D14.2 x D17.9 x 2 -StFA

G ¼, M14 x 1.5

3361485

per DIN 7603 Form C D33.3 x D38.9 x 2.5 -StFA

G 1

11355352

D15 x D21 x 3 -NP-Univ

M24 x 1.5

1605933

D15 x D21 x 1 -NP-Univ

M24 x 1.5

Legend:

CuFA = Copper, max. 45 HB

a

; filled with asbestos-free sealing material

Al

= Aluminium Al99; F11, 32 to 45 HB

b

StFA = Soft iron, 80 to 95 HB

a

; filled with asbestos-free sealing material

6.2 Tapered threads (NPT)

It should be checked whether it may be necessary to seal them additionally with PTFE tape

or hemp. The threads must be lubricated with a suitable lubricant before fitting.

Tighten the threads by hand when carrying out the final assembly on the plant. This will

correspond to the delivery status of the premounted components. The final tightening and

sealing must be made with a spanner (1.5 to 3 rotations).

7. Maintenance and cleaning

7.1 Maintenance

The DiwiTherm

®

thermometer is maintenance-free.

The indicator should be checked once or twice every year.

To do this, the instrument must be disconnected from the process and checked using a

temperature calibrator.

DiwiTherm

®

model TR75: battery powered (at least 10 years service life)

The battery is not replaceable!

Repairs must only be carried out by the manufacturer.

6. Commissioning, operation / 7. Maintenance and cleaning