Maintenance, accessories, Trouble shooting – WIKA WU-16 User Manual

Page 9

2460160.06 GB/D/F/E 01/2010

16 WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio WU-1X

2460160.06 GB/D/F/E 01/2010

17

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio WU-1X

Failure

Possible cause

Procedure

Output signal unchanged after change

in pressure

Mechanical overload through over-

pressure

Replace instrument; if failure reoccurs,

consult the manufacturer *)

Wrong supply voltage or current spike Replace instrument

No output signal

No/incorrect voltage supply or current

spike

Adjust the voltage supply to correspond

with the Operating Instructions *)

Cable break

Check connections and cable

No/False output signal

Incorrectly wired (e.g. Connected as

2-wire instead of 3-wire system)

Follow pin assignment (see Instrument

Label / Operating Instructions)

Abnormal output signal or

Abnormal zero point signal

Zero point set wrongly

Adjust zero point correctly (see chapter

8); a sufficiently accurate current/volt

meter should be used

9. Maintenance, accessories

WIKA transducers require no maintenance.

Have repairs performed by the manufacturer only.

9. Maintenance, accessories

GB

Board Replacement

For board replacement, vent the transducer to pressureless state.

Remove all power to the transducer.

Protect the transducer from voltage, or static discharge, to prevent possible damage.

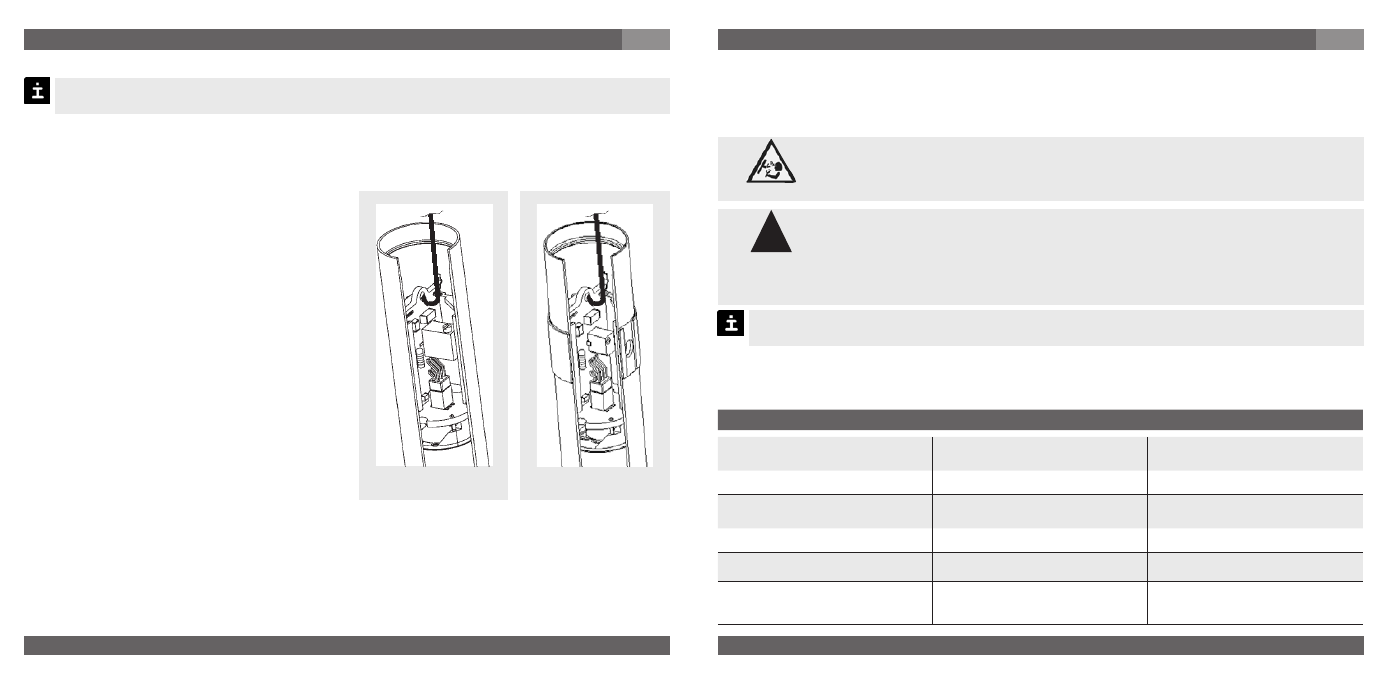

Disassembly

1. Protect the PCB and other electrical

devices from voltage, or static discharge,

to prevent possible damage. Ensure you

have a ground strap attached to your body.

2. Remove the locking ring, on the top of

transducer.

3. Carefully pull the assembly out of the

transducer housing, as far as the internal

con-nector cable will allow. Remove the

4-pin connector from the universal

electron-ics board assembly.

4. Hang the tool supplied with the replacement

PCB into the bore of the PCB.

5. While firmly holding the transducer body,

pull the PCB straight out of the

transducer body assembly.

Reassembly

1. Firmly push the new PCB into the transducer body as far as it will go.

2. Align the pins on the connector from the electrical connector with the sockets on the new

universal electronics board assembly.

3. Rotate the electrical connector on the transducer housing to the keyed insertion.

Replace and hand tighten the locking ring, on the top of transducer.

without side-access

with side-access

9. Maintenance, accessories / 10. Trouble shooting

GB

Accessories: For details about the accessories (e. g. connectors), please refer to WIKA‘s

price list, WIKA‘s product catalog on CD or or contact our sales department.

10. Trouble shooting

Open pressure connections only after the system is without pressure!

Do not insert any pointed or hard objects into the pressure port for cleaning to prevent

damage to the diaphragm of the pressure connection.

Take precautions with regard to remaining media in removed transducers.

Remaining media in the pressure port may be hazardous or toxic!

Remove the transducer from service and mark it to prevent it from being

used again accidentally, if it becomes damaged or unsafe for operation.

Have repairs performed by the manufacturer only.

Please verify in advance if pressure is being applied (valves/ ball valve etc. open) and if the

right voltage supply and the right type of wiring (2-wire/3-wire) has been chosen?

Warning

!

Warning