4 instructions on commissioning – Festo Контроллер крайних положений SPC11 User Manual

Page 26

1. Installation instructions for the DNCI or DDPC

1-12

Festo P.BE-SPC11-DNCI-EN en 1208a English

1.4

Instructions on commissioning

Caution

Incorrectly set parameters result in a deterioration in

positioning behaviour and cause malfunctioning.

•

Be very careful when setting the parameters.

•

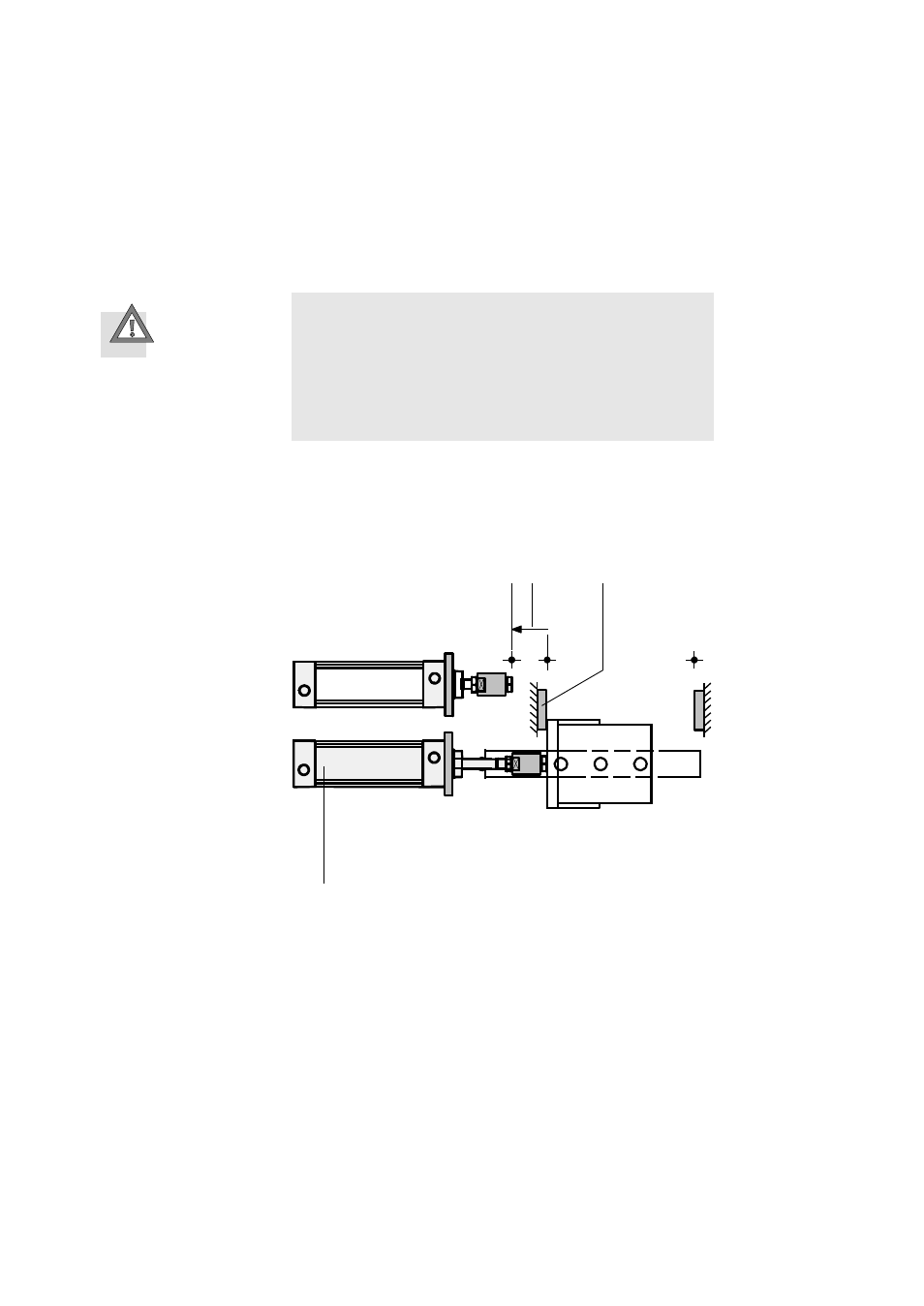

Set the offset axis zero point (r) and the nominal stroke

length (L) precisely to the millimeter.

For good positioning behaviour, the SPC11 must know the

exact positioning range used by the drive. That is why the

SPC11 queries the parameters nominal stroke length (L) and

offset axis zero point (r) during commissioning (see system

manual type P.BE-SPC11-SYS...).

1

Axis zero point

(piston rod run in

2

Offset axis zero

point (r)

3

Fixed stop (here

for end position

P.01)

4

Nominal stroke

length see type

plate

1

2

3

P.01

P.02

4

Fig. 1/4:

Reference points for incremental path measuring systems with SPC11-INC