Festo Неполноповоротный привод DFPB User Manual

Page 5

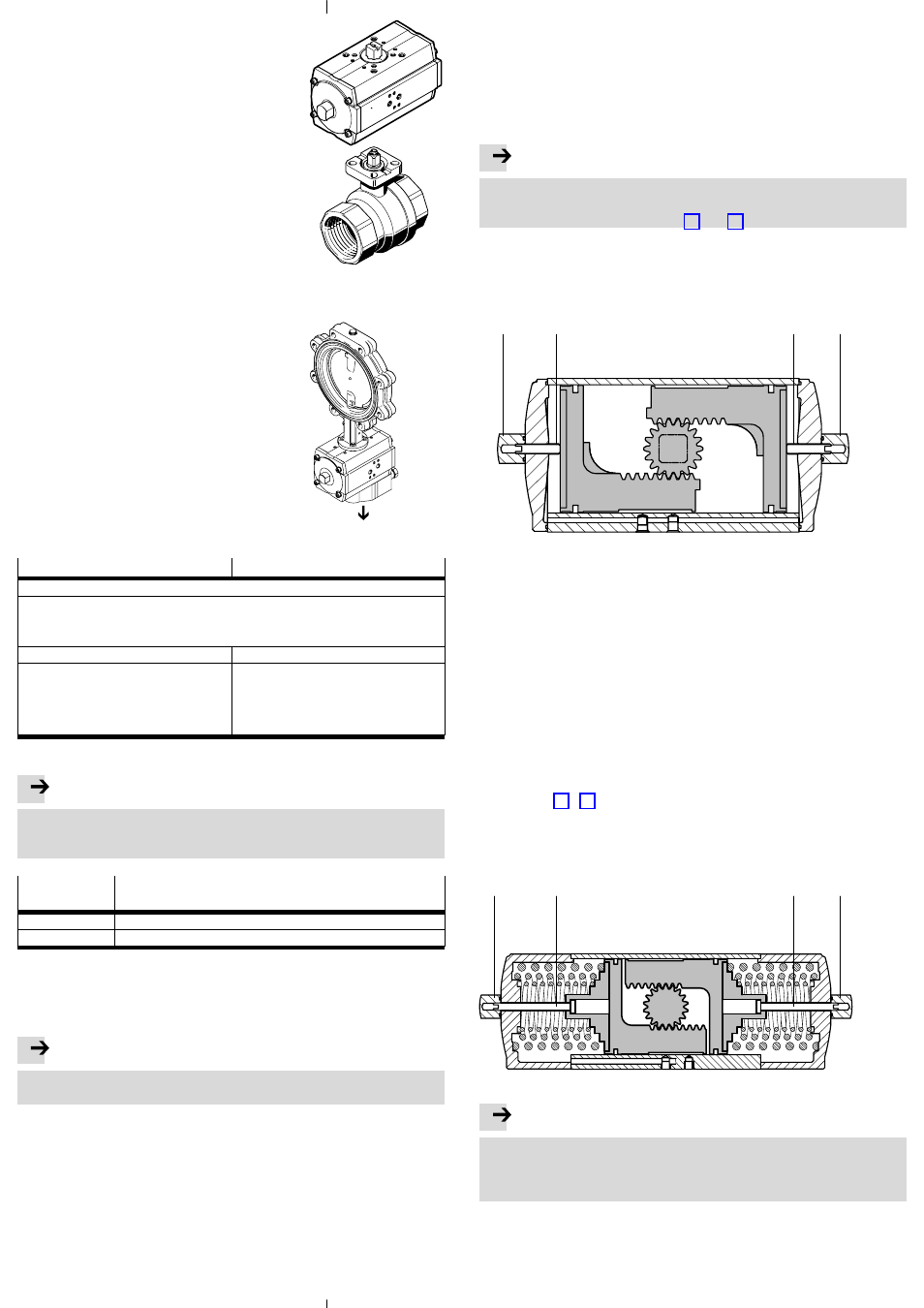

To attach the DFPB onto a process valve:

1. Place the DFPB on the switching shaft of the

process valve.

Make sure here that the square shaft of the

process valve sits in the double−square coupling of

the DFPB without being tilted.

2. Fasten the DFPB to the connecting flange of the

process valve with 4Ăcorrosion−resistant screws.

3. Tighten all the screws in diagonally opposite

sequence.

4.Check that the DFPB turns in the required direction

of rotation and whether the processing valve

assumes the required position.

If the DFPB does not work in the required direction of

rotation, loosen the screws and turn the DFPB to the

attachment of the process valve on the opposite

side.

Fig. 3

In the case of upside−down mounting and

simultaneous sensing by means of a "puck",

appropriate measures must be taken to ensure that

the puck cannot come off the drive together with the

shaft adapter.

Fig. 4

6.2 Pneumatic installation

Connect the tubing for the air supply as follows:

DFPB (double−acting)

DFPB (single−acting)

Air supply at connection 2 (A)āā:

Ĉ The pistons of the semi−rotary drive are pressurized inside and pressed outwards.

Ĉ The transmission shaft

3 rotates in the direction of the arrow (see housing top and bottom)

Ĉ Depending on whether it is installed on the top of the bottom of the DFPB, the process valve

opens or closes.

Air supply at connection 4 (B)āā:

Pressure drop at connection 2 (A)āā:

Ĉ The pistons of the semi−rotary drive are presĆ

surized outside and pressed inwards.

Ĉ The transmission shaft

3 rotates against

the direction of the arrow (see housing top

and bottom)

Ĉ The connected process valve is actuated.

Ĉ The pistons of the semi−rotary drive are presĆ

sed inwards by spring force.

Ĉ The transmission shaft

3 rotates against

the direction of the arrow (see housing top

and bottom)

Ĉ The connected process valve is actuated.

When a DFPB (single−acting) is used in a moist and/or dusty environment:

Note

Moisture and dirt particles can penetrate via exhaust port 4 (B) and destroy the

product.

· Take preventive measures in accordance with the following table.

Ambient

temperature

Remedial action

Moist and dusty

Provide an exhaust feedback at exhaust port 4 (B).

Dusty

Screw a silencer (è www.festo.com/catalogue) into the exhaust port 4 (B).

When a solenoid valve is used:

· Use a solenoid valve with NAMUR port pattern.

7

Commissioning

Note

· Make sure that the operating conditions lie within the permitted ranges

(è Technical specifications).

The product is ready for operation as soon as it is fitted and electrically and

pneumatically connected.

· Make sure that a process valve fitted to the DFPB can be switched without

hindrance.

· Slowly pressurise the DFPB.

7.1 End−position adjustment

The end position setting of the DFPB serves to optimise the opening or closing

reaction of the connected process valve.

The swivel angle of the DFPB variants can be set to ±4°:

Ĉ with double−acting semi−rotary drives, it is possible to set the piston stop only in

the outer end position,

Ĉ with single−acting semi−rotary drives, it is possible to set the piston stop only in

the inner end position.

Note

The semi−rotary drive is only seal−tight when the locking nuts are tightened.

· When operating the DFPB, make sure that the adjusting screws

9 or aJ are

secured with the locking nuts

7.1.1 End−position adjustment for double−acting DFPB

Preparation for setting the outer end position of the double−acting DFPB

1. Turn the locking nuts

7 down on both sides of the DFPB.

2. Briefly pressurise the DFPB at the port 2 (A). The pistons move to the outer end

position.

7

9

7

9

Fig. 5

Setting the outer end position of the double−acting DFPB

1. Exhaust the DFPB.

2. Using an Allen key, turn the adjusting screw

9 clockwise until the connected

process valve reaches the desired position.

3. Turn the opposite adjusting screw

9 clockwise until you feel resistance. Make

sure that this does not change the position of the connected process valve.

4.Pressurise the DFPB and check whether the connected process valve reaches

the desired position.

Expanding the outer end position of the double−acting DFPB:

5. Exhaust the DFPB.

6. Using an Allen key, turn the adjusting screws

9 just a few turns

counter−clockwise out of the housing of the DFPB.

7. Pressurise the DFPB at the port 2 (A) again.

The pistons move to the expanded outer end position.

7.1.2 End−position adjustment for single−acting DFPB

Preparation for setting the inner end position of the single−acting DFPB

1. Exhaust the DFPB.

2. Turn the locking nuts

7 down on both sides of the DFPB.

7

aJ

7

aJ

Fig. 6

Note

Risk of damage to the device.

· Ensure that the adjusting screw is never screwed all the way into the cover,

as this prevents end−position adjustment, thus necessitating repair.

See

Chapter 9, Disassembly and repair".