Semi−rotary drive dfpb – Festo Неполноповоротный привод DFPB User Manual

Page 4

Semi−rotary drive DFPB

(en) Operating instructions

Original: de

749 613

0911b

Note

Fitting and commissioning is to be carried out only by qualified personnel in

accordance with the operating instructions.

1

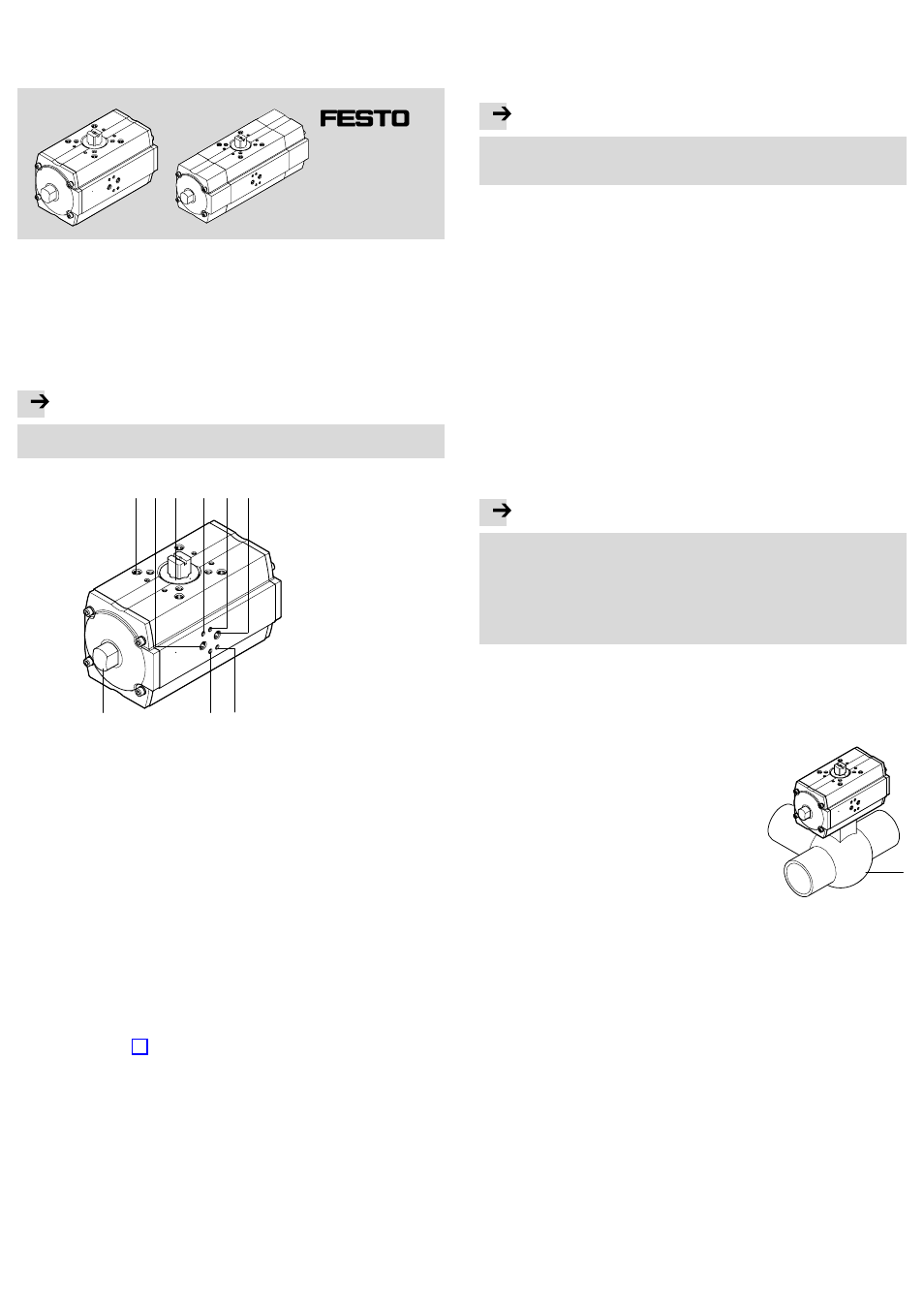

Operating elements and connections

1 2 3

5 6

4

4

5

Fig. 1

7

1

Different mounting threads on the

top and bottom of the DFPB for

installing a process valve or a limit

switch attachment

2

Port 2 (A) for the air supply for

actuating the switching shaft of

the DFPB in the direction of the

arrow (see housing top and

bottom)

3

Transmission shaft for mounting

the switching shaft of the process

valve or for mounting a square for

the limit switch attachment

4

Mounting thread for a solenoid

valve with NAMUR port pattern

5

Mounting thread for threaded pins

for aligning the NAMUR solenoid

valve

6

Port 4 (B) for the air supply for

actuating the switching shaft of

the DFPB against the direction of

the arrow (see housing top and

bottom)

7

Locking nut (for locking the

adjusting screws)

2

Function

Pressurizing the cylinder chambers causes the pistons in the DFPB to move back

and forth. Linear motion is converted into rotary motion by means of a rack and

pinion combination. A screwed−on process valve records the moment of reaction of

the DFPB. You can find the permissible nominal torque in the type designation of

the respective DFPB è Fig. 8.

3

Application

The DFPB semi−rotary drive is tailored completely to the requirements of the

processing industry. It is used for controlling media−flow process valves in systems.

The drive is properly used for process valves with a range of movement limited to

90°, suchĂas ball valves and butterfly valves (quarter turn actuators).

Use as a cushioning or shock absorbing element is not proper use. This may result

in excessive loads.

4

Transport and storage

· Ensure storage conditions as follows: short storage times in cool, dry, shaded

and corrosion−protected locations.

5

Conditions of use

Note

Incorrect handling can result in malfunctioning.

· Make sure that all the instructions in this chapter are observed. This way the

product will perform as intended.

· Use the product in its original state. Unauthorised modification is not permitted.

· Ensure that all applicable national and local safety laws are adhered to.

· Remove the packing except for the adhesive labels on the compressed air

connections (to prevent dirt).

· The packing is intended for recycling (except for: oiled paper = other waste).

· Compare the maximum values specified in these operating instructions with your

actual application (e.g. pressures, forces, torques, masses, response times,

temperatures). The product can only be used in accordance with the relevant

standards if the maximum load limits are observed.

· Take into consideration the ambient conditions at the location of use. Corrosive

environments reduce the service life of the product.

· Protect the device from fluctuations in pressure and excess operating

temperature. Use control valves for regulating pressure and excess pressure.

· Ensure that there is a supply of correctly prepared compressed air. The product

requires dried compressed air, lubricated or unlubricated.

· Use only non−lubricated compressed air under normal conditions.

The DFPB possesses an initial lubrication which suffices for the complete service

life.

Note

Continuous operation at the limits of the specified ambient temperature and

work frequency can reduce the service life of the semi−rotary drive.

· Use lubricated compressed air for continuous operation under extreme condiĆ

tions. The oil must be chemically inert and must not carbonise.

Using lubricated compressed air flushes out the initial lubrication.

· From that point onwards, the DFPB must be operated only with lubricated

compressed air.

If the DFPB is used in a potentially−explosive atmosphere:

· Please observe the notes and instructions in the accompanying ATEX special

documentation.

6

Fitting

The installation of the DFPB onto a process valve is

done in accordance with the desired direction of

rotation.

When a 3−way process valve

8 is used:

· Align the semi−rotary drive so that the connection

openings face the side without tubing. The

pneumatic connection must have a free working

space.

Fig. 2

8

6.1 Mechanical installation

· In order to fit the DFPB semi−rotary drive, set the switching shaft of the process

valve so that the desired working method for opening and closing the process

valve is implemented.

Observe the switching direction of the DFPB, shown by means of arrows on the

top and bottom of the device.

· Note that a process valve with butterfly valve can only be opened in one

direction.

· Note that the end position of the swivel motion can be adjusted:

ć on double−acting devices only in the direction of the arrow

ć on single−acting devices only against the direction of the arrow.