Maintenance, Bearing maintenance, Regrease the grease-lubricated bearings – Bell & Gossett P81673 REV I Series 1510 User Manual

Page 29: Lubricating grease requirements

Maintenance

Bearing maintenance

Bearing lubrication schedule

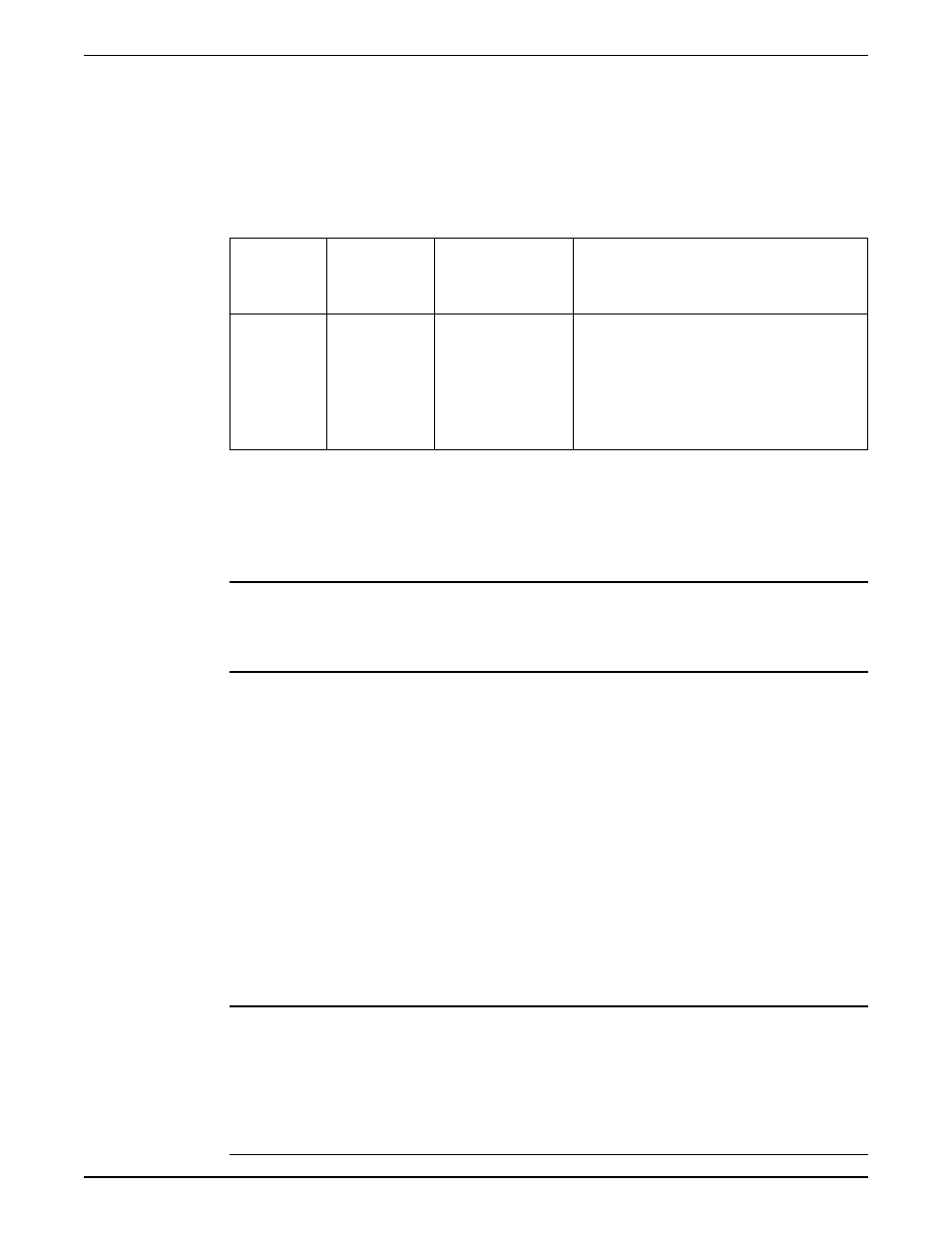

Type of bearing First lubrication,

assembled pumps

and replacement

bearing frames

First lubrication,

replacement bearings

Lubrication interval, pump, polyurea-based grease,

operating hours

Grease-

lubricated

bearings

Not applicable,

lubricated before

shipment

Hand pack bearings

before pressing on the

shaft. After bearing

frame assembly, follow

relube instructions to

lube bearings.

• 3600 hours, 2 pole

• 7200 hours, 4 pole

• 50% for severe conditions: dirty, wet and/or

above 100°F (38°C) ambient

• 50% for bearing frame temperature above

180°F (82°C)

• 75% for lithium-based grease

Regrease the grease-lubricated bearings

It is important to lubricate pumps and motors that require regreasing with the proper

grease. See the motor service instructions and nameplate for motor regreasing

information. Pumps are to be regreased using the grease types listed below or approved

equal. Always keep pump and motor properly lubricated.

NOTICE:

Make sure that the grease container, the greasing device, and the fittings are clean.

Failure to do this can result in impurities entering the bearing housing when you regrease

the bearings.

1. With fully enclosed coupling guards, regrease pump while pump is running.

a) With old style open ended guards, stop pump, re-grease, and hand turn shaft

before re-starting.

2. Wipe dirt from the grease fittings before greasing.

3. Fill both of the grease cavities through the fittings with the recommended grease.

Stop when grease leaks out at shaft.

4. If needed, stop pump and wipe off excess grease.

5. Restart pump.

The bearing temperature usually rises after you regrease due to an excess supply of

grease. Temperatures return to normal in about two to four operating hours as the pump

runs and purges the excess grease from the bearings. Maximum normal bearing housing

temperature for polyurea-based grease is 225°F (107°C) and for lithium-based grease

180°F (82°C).

Lubricating grease requirements

NOTICE:

• Never mix greases of different consistencies (NLGI 1 or 3 with NLGI 2) or with different

thickeners. For example, never mix a lithium-based grease with a polyurea-based

grease. This can result in decreased performance.

• Remove the bearings and old grease if you need to change the grease type or

consistency. Failure to do so can result in equipment damage or decreased

performance.

Maintenance

Series 1510 Installation, Operation, and Maintenance Manual

27