Prepare for alignment, Align the pump using a straight edge and calipers – Bell & Gossett P81673 REV I Series 1510 User Manual

Page 19

• Only perform alignment by moving or shimming the motor.

• Since adjustments in one direction can alter the alignment in another direction, check

the alignment in all directions after you make a correction.

• Make sure that the pump and motor bolts are tight when you take all measurements.

• Perform a final alignment check after the unit reaches its final operating temperature.

Prepare for alignment

1. Check the pump and motor shafts and remove any paint, burrs, and rust.

2. Slide the hubs and bushings on the shafts with keys.

3. Hold one half element on the hubs in order to determine the appropriate hub

spacing.

4. If you use spacer elements with high speed rings, hold both half elements on the hubs

in order to make sure the hubs do not interfere with the rings.

5. You can install the hubs with the hub extension facing in or out.

Make sure the shaft extends into the hubs at least 0.8 times the diameter of the shaft.

6. Lightly fasten the hubs to the shafts in order to prevent them from moving during

alignment.

7. Align the hubs to the values shown in Maximum allowable misalignment for Rexnord

Omega couplings.

You can perform alignment with lasers, dial indicators, or with a straight edge and

calipers.

Align the pump using a straight edge and calipers

1. Check the angular misalignment:

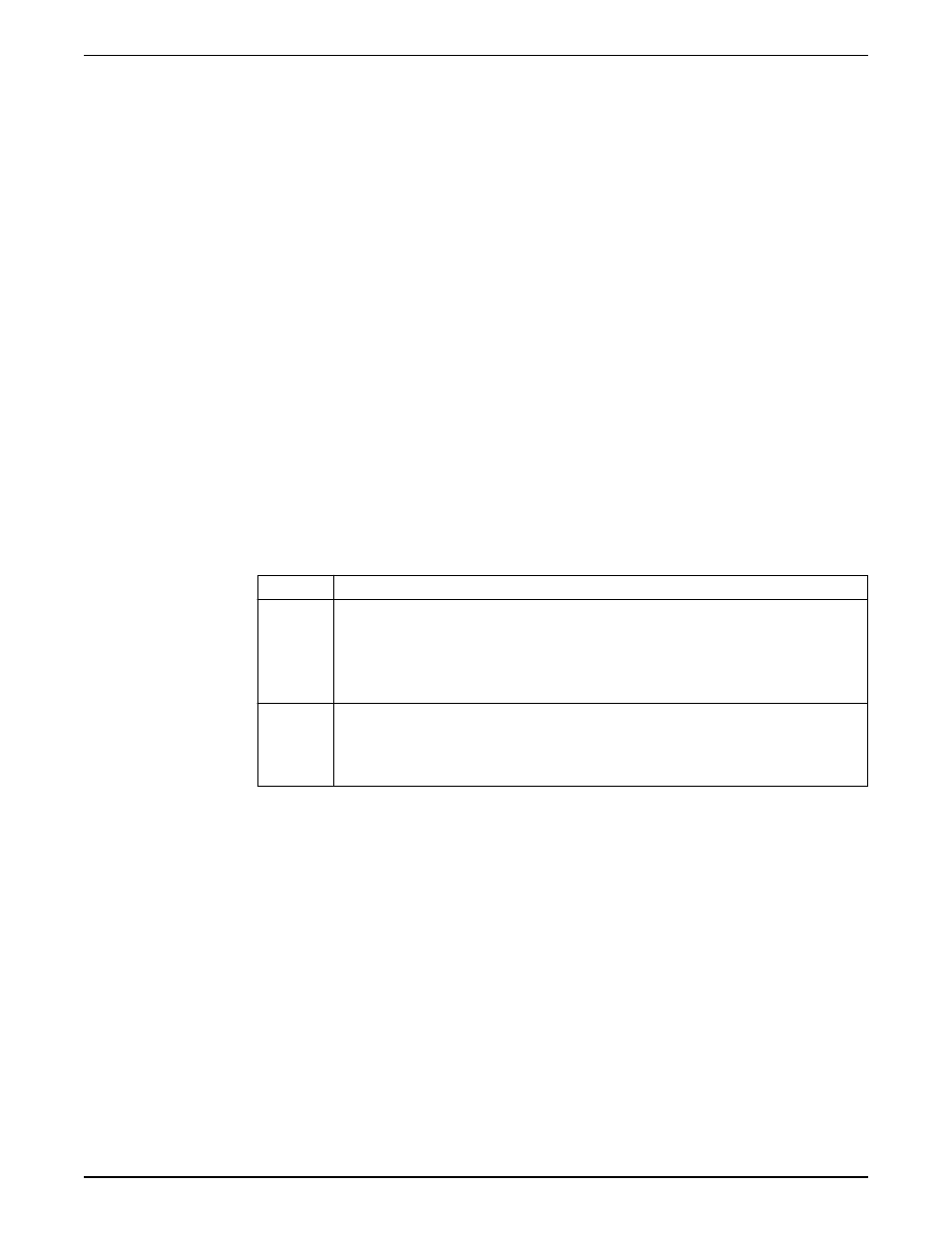

Tool

Procedure

Calipers

1. Gauge the distance between the two hubs at various points around the circumference.

Do not rotate the shafts.

2. Reposition the equipment until the difference between the minimum and maximum

distance values is within the permissible range.

See Maximum allowable misalignment for Rexnord Omega couplings.

Feeler

gauges

1. Insert feeler gauges between the coupling faces at various points around the circumference.

Do not rotate the shafts.

2. Reposition the equipment until the difference between the minimum and maximum

distance values is within the permissible range.

2. Check the parallel alignment:

a) Place a straight edge across the two hubs.

b) Measure the maximum offset at various points around the periphery of the hubs.

Do not rotate the shafts.

c) Reposition the equipment until the offset is within the permissible range.

See Maximum allowable misalignment for Rexnord Omega couplings.

A E10 coupling with a 3° angular misalignment will have a 0.191 in. (0.485

cm) difference in measurements between L1 and L2. This is within the 0°

to 4° misalignment that is allowed for that size of coupling.

Installation

Series 1510 Installation, Operation, and Maintenance Manual

17