NOVUS RHT-XS User Manual

R h t - x s

INSTALLATION

The RHT-P10 electronic housing is designed for wall mounting, while its remote sensor probe is

intended for inserting and screwing in a flange.

Remove the housing front panel to access the two fixing holes, shown in Figure 07.

Figure 06 – Electronic module dimensions

Figure 07 – Fixing holes

Figure 08 – Remote sensor model dimensions (mm)

ELECTRICAL CONNECTIONS

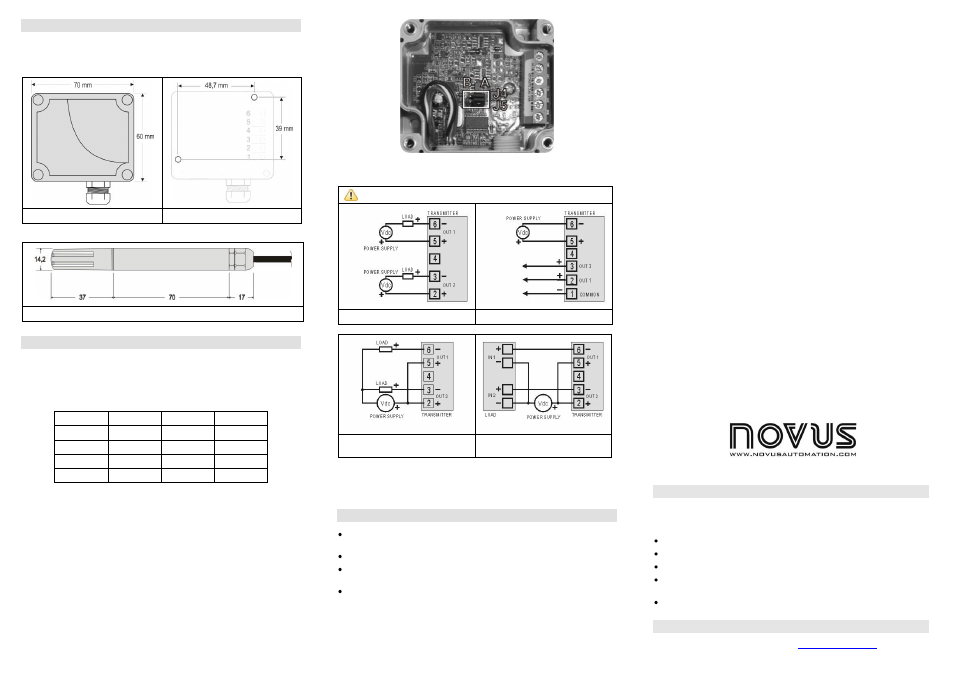

The transmitter can be ordered as 4-20 mA current output or 0 to 10 Vdc voltage output. The

output signal is defined on purchase and cannot be later changed.

Variables can be monitored together or separately. Combinations of mobile jumpers J4 and J5

within the transmitter case define how variables will be used. The jumpers also define the

transmitter terminals with available output signals.

Jumper J5

Jumper J4

OUT1

OUT2

Position A

Position A

Temperature

Humidity

Position A

Position B

Temperature

Off

Position B

Position A

Humidity

Off

Position B

Position B

Humidity

Temperature

Table 01 – Configuration of OUT1 and OUT2 outputs

Figure 10 – J4 and J5 position within the transmitter

Figures 11 and 12 show the required electrical connections.

Check that loop OUT1 must always be powered in 4-20 mA model!

Figure 11a – 4-20 mA connections

Figure 12a – 0-10 Vdc connections

Figure 11b – 4-20 mA connections with single source

Figure 12b – 4-20 mA model with single source

and load with two input channels

LOAD represents the output signal measurement equipment (controller, register, etc.).

The connection wires go inside the transmitter trough to the cable gland mounted in the

transmitter case.

INSTALLATION RECOMMENDATIONS

Conductors of small electrical signals must be distant from activation or high-tension/current

conductors, preferably passing through grounded conduits.

A specific electrical power supply network should be provided for instruments use only.

In controlling and monitoring applications, possible consequences of any system failure

must be considered in advance.

RC filters (47 R and 100 nF, serial) in inductor charges (contactors, solenoids, etc.) are

recommended.

H U M I D I T Y A N D T E M P E R A T U R E T R A N S M I T T E R

R H T - X S

O P E R A T I N G M A N U A L

Man 5000282

ATTENTION

The calibration of the humidity sensor may change in case it is exposed to contaminating vapors

or to high humidity and temperature conditions for extended periods. In order to speed up the

calibration restoration, proceed as described below:

Remove the sensor from the capsule.

Wash it with water in case there are solid particles on it.

Place it within a 80 °C (+-10 °C) oven for 24 hours.

Place it for 48 hours in a place with a temperature between 20 and 30 °C and humidity over

75 % RH.

Place the sensor back in the capsule.

WARRANTY

Warranty conditions are available on our web sit