NOVUS N322T User Manual

Page 2

Tib

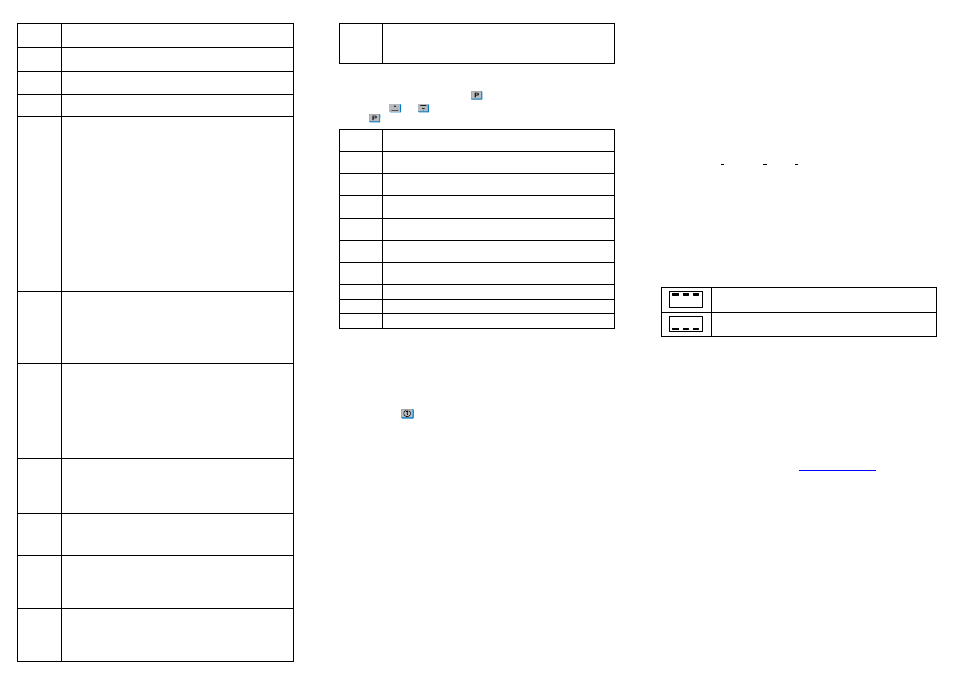

T1 Base - Time base for t1:

0

Seconds

1

Minutes 2

Hours

t2b

T2 Base - Time base for t2:

0

Seconds

1

Minutes 2

Hours

t1

Time 1 - Adjusts the interval between consecutive output relay pulses, from 0

to 999 units of t1b.

t2

Time 2 - Timer output pulse duration, adjustable between 1 and 999 units of

t2b

.

fot

Force timer:

0

Timer period and duration t1 and t2 act regardless of the control output

status.

1

Timer output is activated together with the control output. When the

control output is turned off, the timer works as configured in t1 and t2,

T2

first.

2

The process will begin only when the key is pressed for more than 1

second to light up so the flag P3 if pressed again for more than 1

second, the process will be shut down indicating by a beep along with

flags P1 and P2. When the temperature reach set point programmed for

the first time, the flag P3 will flash indicating that the timer has been

activated. When the scheduled time is reached, is disabled by turning the

output 1 and P3 flag triggering the alarm as the ALE parameter. When

this function is enabled, t1 and cnt are automatically zeroed and

should remain at zero.

For defrost applications, configure Fot=0.

Not used for thermocouple inputs.

Function 2 available only for models N322T-NTC and N322TB-NTC.

dfh

Defrost hold - Holds the temperature indication constant during the defrost

time plus the time defined in dFh. Not valid for thermocouple inputs.

0

Display indicates actual temperature;

1

a 250 Time, in seconds, minutes or hours, following the defrost, in which

the indication remains constant, showing the temperature measured just

before the defrost cycle.

When the defrost function is not used, configure dFh=0.

df(

Defrost compressor - Output (OUTPUT1 - compressor) behavior during

defrost:

0

OUTPUT1 é turned off during defrost;

1

OUTPUT1 remains ON during the defrost;

3

OUTPUT1 acts regardless of the defrost cycle (controls the output

normally, according to the programmed setpoint).

In refrigeration systems, OUTPUT1 is the normal compressor output.

When defrost is not used, configure df(=2.

Not valid for instruments with thermocouple input.

(pE

Compressor protect - Enables compressor protection by voltage monitoring. If

the network voltage is not between the SetPoints (PL and (PK.

0

Disables compressor protection.

1

Enable compressor protection.

Function available only for model N322T-NTC-LVD.

(Pt

Compressor protect time - Determines a delay in the compressor shutting

down when compressor protection's activities by voltage monitoring. Adjustable

time interval between adjustable between 5 to 30 seconds.

Function available only for model N322T-NTC-LVD.

(PL

CP low limit - Voltage lower limit used by the compressor protection. Voltage

minimum value that the compressor can operate.

Parameter adjustable between 150 to 254 Vac must be obligatorily 10 Vac lower

than the value set at the higher limit ((PH).

Function available only for model N322T-NTC-LVD.

(PH

CP high limit - Voltage lower limit used by the compressor protection. Voltage

minimum value that the compressor can operate.

Parameter adjustable between 150 to 254 Vac must be obligatorily 10 Vac

higher than the value set at the lower limit ((Pl).

Function available only for model N322T-NTC-LVD.

Add

Address - Controllers with the optional RS485 Modbus RTU communication

interface have the Add parameter at the Configuration level. Set a unique

Modbus address for each equipment connected to the network. Address range

is from 1 to 247.

Level 3 – Calibration level

The controller is factory calibrated. The following parameters should be accessed only by

experienced personnel. To enter this cycle, the

key must be kept pressed for 4 seconds.

Don’t press the

and

keys if you are not sure of the calibration procedures. Just

press the

key a few times until the temperature measurement level is reached again.

pas

Password - Enter the correct password to unlock write operations for the

parameters in the following levels.

[Al

Calibration low - Offset value of the input. It adjusts the lower measurement

range of the sensor.

[Ak

Calibration high - Gain calibration. It adjusts the upper measurement range of

the sensor.

[JL

Cold junction offset calibration - This parameter is available only for

thermocouple.

FA(

Factory calibration - Restores factory calibration parameters. Change from 0 to

1 to restore the calibration parameters with factory values.

Prt

Protection - Defines the levels of parameters that will be password protected.

See "Configuration Protection" for details.

Pa(

Password change - Allows changing the current password to a new one. Values

from 1 to 999 are allowed.

Sn2

Serial number - First part of the controller electronic serial number.

sn1

Serial number - Second part of the controller electronic serial number.

sn0

Serial number - Third part of the controller electronic serial number.

WORKING WITH THE CONTROLLER

The controller cycles the control output as to maintain the system temperature at the value

configure in the Setpoint parameter. The display P1 sign is shown whenever the control output is

activated.

The timer output is typically used for the system defrost. The t1 and t2 parameters define,

respectively, the interval and duration of the defrost cycles.

Manual Defrost: the

key allows for the timer start or reset. Pressing this key for at least 1

second, the timer output is toggled.

The display P2 sign lights when the timer output is on. The timer output is usually used for defrost

in refrigeration systems. In different applications it can be used to periodically start other loads,

such as a mixer, fan, etc.

CONFIGURATION PROTECTION

A protection system to avoid unwanted changes to the controller parameters is implemented. The

level of protection can be selected from partial to full. The following parameters are part of the

protection system:

Pas

When this parameter is presented, the correct password should be entered to allow

changes of parameters in the following levels.

Prt

Defines the level of parameters that will be password protected:

1 - Only calibration level is protected (factory configuration);

2 - Calibration and Configuration levels are protected;

3 - All levels are protected - calibration, Configuration and setpoints.

PA(

Parameter for definition of a new password. Since it is located in the calibration level,

can only be changed by a user that knows the current password. Valid passwords are in

the range 1 to 999.

Configuration protection usage

PAS

parameter is displayed before entering a protected level. If the correct password is entered,

parameters in all following levels can be changed. If wrong or no password is entered, parameters

in the following levels will be read only.

Important notes:

1 - After five consecutive attempts to enter a wrong password, new tentative will be blocked for the

next 10 minutes. If the current valid password is unknown, the master password can be used

only to define a new password for the controller.

2 - The password for a brand new device is 111.

MASTER PASSWORD

The master password allows user to define a new password for the controller, even if the current

password is unknown. The master password is based in the serial number of the controller, and

calculated as following:

[ 1 ] + [ higher digit of SN2 ] + [ higher digit of SN1 ] + [ higher digit of SN0 ]

for example the master password for the device with serial number 987123465 is: 1 9 3 6

as follows: 1 + sn2= 987; sn1= 123; sn0= 465 = 1 + 9 + 3 + 6

How to use the master password:

1 - Enter the master password value at PaS prompt.

2 - Go to PA( parameter and enter the new password, which must not be zero (0).

3 - Now you can use this new password to access all controller parameters with modify rights.

ERROR MESSAGES

Sensor measurement errors force the controller outputs to be turned off. The cause for these

errors may have origin in a bad connection, sensor defect (cable or element) or system

temperature outside the sensor working range. The display signs related to measurement errors

are shown below:

Measured temperature exceeded maximum allowed range for the sensor.

Broken Pt100, Pt1000 or T/C. Short circuited NTC sensor.

Measured temperature is below minimum measurement range of the sensor.

Short circuited Pt100, Pt1000 or T/C. Broken NTC.

COMPRESSOR PROTECTION (N322T-NTC-LVD)

The controller constantly monitors the voltage of power network and shuts the compressor if this

tension is not within limits. These limits are defined in parameters (PL and (Pk, adjustable

between 150 and 254 Vac. In addition to turning the compressor off, the driver passes the signal on

your display this occurrence: Toggles the indication of voltage value measured with the

temperature value.

When the voltage exceeds limits (lower than 150 Vac and higher than 254 Vac) is signaling to

indicate temperature alternating with the message 0.

WARRANTY

Warranty conditions are available on our web sit