Successive repetitions of a program, Determination of pid parameters, Alarms functions – NOVUS Controller N960 User Manual

Page 5: Problems with the controller

N960 Controller

NOVUS AUTOMATION

5/6

SUCCESSIVE REPETITIONS OF A PROGRAM

The elaborated program can be repeated several times, always

restarting immediately after each execution.

The rPt.p (rePeat Program) parameter, in the Program cycle,

configures the number of times the program must be REPEATED. It

determines the number of executions beyond the initial execution.

With zero (0), the program is executed only one time. It will not be

repeated.

Important: After the last execution of the program, all controller outputs

are turned off and the RUN parameter changes to OFF.

DETERMINATION OF PID PARAMETERS

During the automatic tuning the process is controlled in ON / OFF

mode in the programmed SP - the Ramp to Level function is disabled.

The automatic tuning may take many minutes to the concluded,

particularly in slow processes. Some recommendations for the

automatic tuning process are:

• Program SP to a value close to the point at which the process

will operate after tuning.

• Enable automatic tuning on the “Atvn” screen by selecting

yes

.

• Program the value yes on the “rvn” screen.

The “TUNE” indicator on the display stays lit until the completion of the

automatic tuning process.

During the execution of automatic tuning, large oscillations can be

induced in the process around the set point. Check if the process

supports these oscillations.

If the automatic tuning does not result in a satisfactory control, refer to

Table 3 for guidelines on how to correct the behavior of the process.

PARAMETER

VERIFIED PROBLEM

SOLUTION

Proportional Band

Slow answer

Decrease

Great oscillation

Increase

Rate of Integration

Slow answer

Increase

Great oscillation

Decrease

Derivative Time

Slow answer or

instability

Decrease

Great oscillation

Increase

Table 3 - Guidance for manual adjustment of the PID parameters

ALARMS FUNCTIONS

The minimum and maximum alarms are used to signalize extreme

temperature values. These extreme values are defined on the “A1SP”

and “A2SP” screens.

Differential alarms are used to signalize deviations between temperature

and set point control (SP). Values defined by user on the “A1SP” and

“A2SP” screens represent the values of these deviations.

Initial blocking prevents alarm activation when the controller is turned

on until the temperature reaches the SP value for the first time.

The error alarm in the sensor allows to signalize errors in the sensor.

The Level End Function (End.t) determines that the alarm be activated

the end of the level.

With Event Alarm, an alarm is activated during execution of a certain

program segment.

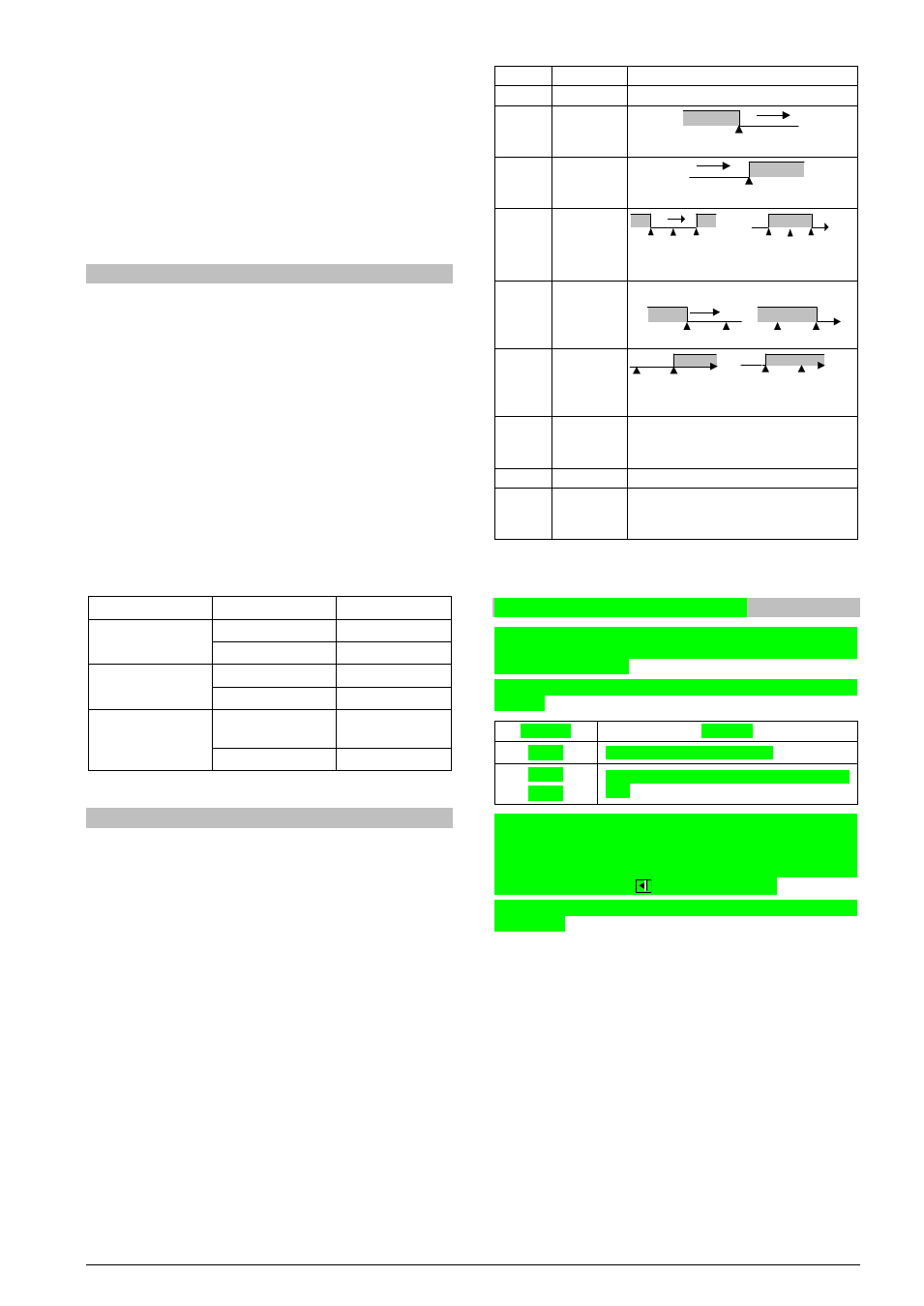

Table 4 illustrates the operation of each alarm function, using alarm 1

as an example, and presents its identification code on the “A1Fv” e

“A2Fv” screens.

Using the Alarm 1 as example.

PROMPT

TYPE

ACTION

Off

Disabled

Output is not used as alarm.

Lo

Minimum

value

(Low)

SPAn

PV

ON

Ki

Maximum

value

(High)

SPAn

PV

ON

Dif

Differential

(diFerential)

SV

PV

SV + SPAn

SV - SPAn

ON

ON

SV

PV

SV - SPAn

SV + SPAn

ON

Positive SPAn

Negative SPAn

Difl

Minimum

Differential

(diFerential

Low)

SPAn positivo SPAn negativo

SV

PV

SV - SPAn

ON

SV

PV

SV - SPAn

ON

Difk

Maximum

Differential

(diFerential

High)

SV

P

SV + SPAn

ON

SV

PV

SV + SPAn

ON

Positive SPAn

Negative SPAn

Ierr

Sensor Break

(input Error)

Activated when the input signal of PV is

interrupted, out of the range limits or

Pt100 in short-circuit.

End.T

End of Level Activate at the end of the level time.

Rs

Event

(ramp and

Soak)

Can be activated at a specific segment of

program.

Table 4 – Alarm functions

Where SPAn refers to Setpoints of Alarm SPA1 and SPA2.

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most common

errors found during the controller operation. A final review may avoid

loss of time and damages.

The controller displays some messages to help the user identify

problems.

MESSAGE

PROBLEM

----

Open input. Without sensor or signal.

Err1

Err6

Configuration or connection problem in the Pt100

cable

Other error messages displayed by the controller can account for errors in

the input connections or type of selected input non compliant with the

sensor or signal applied to the input. If errors persist, even after a review,

contact the manufacturer. Inform also the device serial number. To find

out the serial number, press

for more than 3 seconds.

This information is necessary for eventual contact with the controller’s

manufacturer.