Electrical connections, Option switches, Track selection – HID Magnetic Stripe Reader 740 Installation Guide User Manual

Page 2: Installation instructions, Powering on and self-test, Diagnostic tests

Electrical Connections

Connections from the reader cable to the host cable should be

crimped or made with twist-on wire nuts. Unplug the reader

connector before making the following splices

NOTE: The two blue wires connect to the HEATER BAR which

must be powered by a 24VAC or 24ADC source (3110-7402

Reader only).

Control and data lines are normally High (+5V) when idle and

pulled to common when active (less than 1V).

Two 22GA White wires convey the status of a tamper switch

that indicates whether the reader is properly mounted or

detached. The switch is CLOSED when the reader is mounted

and OPEN when it is detached.

Option switches

To set the reader options, you must know:

1 Are the cards coded with EMPI or ANSI data?

2. Are the cards coded on track I or track II?

3. Does the host system expect Wiegand 26-bit, Wiegand

34-bit or clock-and-data format?

3110-7401 Options

A

B

C

off

on off EMPI

Wiegand

26-bit

off

on on EMPI

Wiegand

34-bit

on

off off ANSI clock-and-data all bits

on

off on ANSI all bits Wiegand

on

on off ANSI Wiegand 26-bit

on

on on ANSI Wiegand 34-bit

“D” IS NOT USED-SET TO OFF

These selections cover the most common uses. If they do not

serve your application, consult your system supplier for their

setup method.

Track Selection

Readers are shipped reading the track II physical location. If

your card is coded on track 1, disassemble the read head

assembly and rotate the reading head 180 degrees.

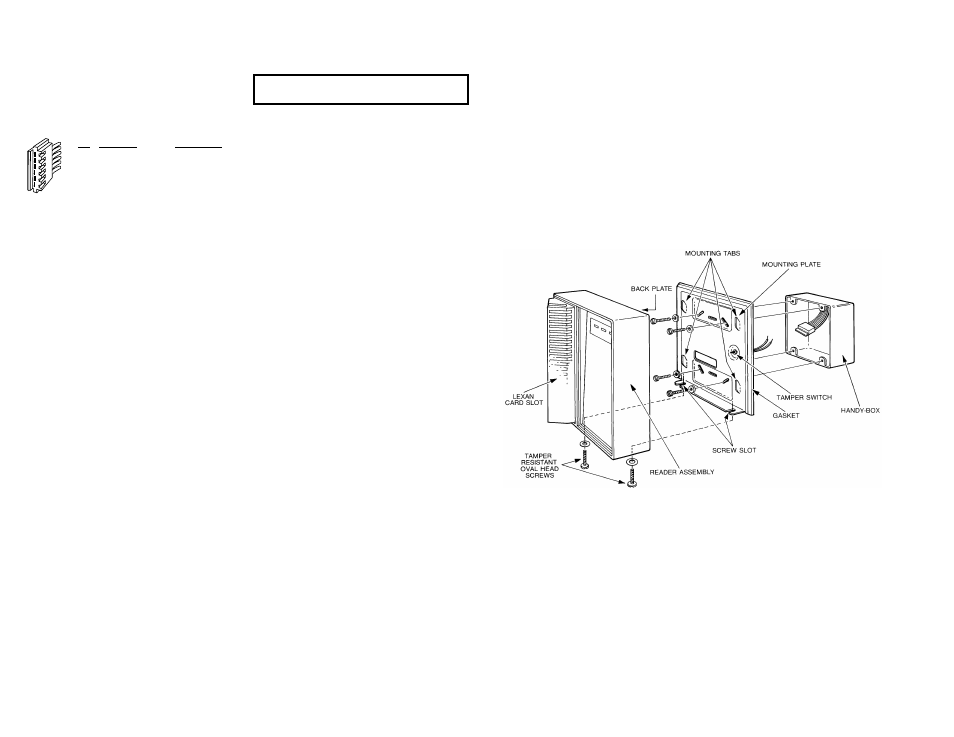

Installation Instructions

CAUTION

Before touching any internal reader parts, touch a grounded

surface to discharge static electricity from your body.

1.

If not mounting to an electrical handy-box, select a suitable

flat surface and use the mounting plate both as a template

to establish drill hole location and as a guide to remove

sufficient material to allow clearance for connection of the

pig-tail to the wiring cable, and the tamper switch. The

tamper switch can be found in the hardware package. If

desired, it can be installed either as shown, or to the back

plate with the tamper switch plunger facing the mounting

plate. A hole in the back plate is provided for this purpose.

2. Pull the required cable between host controller and reader

mounting location. Connect the wire cable to the host.

3. To install, you must first disassemble the reader assembly

from the mounting plate. Use the special oval head screw

driver (AVSAFE driver obtained separately) to loosen the

(2) tamper resistant oval head screws from the bottom of

the reader.

NOTE: It is not necessary to fully remove screws. Just loosen

enough to remove the mounting plate. This will simplify re-

assembly.

4. Attach the provided pig-tail connector to the wire cable at

the mounting location. Connections can be crimped or

made with twist-on wire nuts. Follow the appropriate color

code and wire lead function.

5. Pass the connector through the cut-out in the mounting

plate, and mount the plate to the mounting surface using

the appropriate mounting holes in the plate. The type of

mounting bolts (not provided) will be determined locally by

the installer. They must provide a strong secure mounting.

6. Make sure the wire nuts, or crimped connectors are

located in the wall cavity, and only the pig-tail connector

passes through the mounting plate.

7. Plug the connector into the back of the reader circuit

board. The connector is designed to fit only one way.

Carefully align the pin terminals of the circuit board with

the corresponding holes in the connector and gently push

together with a slight rocking motion.

If not already accomplished, set the appropriate

option switches on the back of the reader circuit

board.

8. Attaching the reader assembly to the mounting plate is the

reverse of disassembly. Carefully align the (4) mounting

tabs on the mounting plate with their corresponding slots in

the back plate. Make sure the (2) oval head screws until

the reader assembly is pulled firmly against the mounting

surface. Do not over tighten these screws.

NOTE: This operation also depresses the tamper switch

plunger.

9

.

Test the reader as appropriate.

Powering On and Self-test

Upon first application of power, the reader does a self-test

sequence. Observe that the reader's Green LED flashes four

times.

If the reader does not make the above confirmation or

continues with short double flashes, the self-test has failed and

the reader must be replaced.

Diagnostic Tests

If the reader completes the self-test by flashing the LED but will

not read cards the following steps apply:

1.

Check that the voltage at the red and black wires is

between 8.0 and 13.0 VDC.

2.

Verify wiring to the host controller.

3.

Test reader by exchanging with another unit.

1

2

3

4

5

6

PIN FUNCTION

WIRE COLOR

1

+12 VDC

RED

2

LED Control Line A

BROWN

3

Data "1" /Data

WHITE

4

Data "0" /Clock

GREEN

5

COMMON

BLACK

6

LED Control Line B

YELLOW

HEATER

BAR BLUE

4.

Do not attempt to adjust the reading head or its mount. It

is factory calibrated and not field serviceable.

Internal damage or electronic failure requires replacement

of the complete reader.