HID Magnetic Stripe Reader 644 Installation Guide User Manual

Page 2

Comparison Number Check

1.

When using the EMPI I or EMPI II encrypted card format,

each user organization, or location is assigned a unique

sequential number called a "Job Code" which is used to

administer that card account and to reorder cards.

2. The "Job Code" is also used to generate a unique,

random, never repeated elsewhere, 16-bit number. For

added security, this number and the card ID number is

encoded on the EMPI Card in an encrypted format. When

the EMPI Card is read, the reader converts this number

into the "Comparison Number".

3. If the host controller accepts 34-bits, enter into host

memory the full 16-bit "Comparison Number" found on the

label of your EMPI Card carton.

4. If the host controller accepts 26-bits, enter into host

memory the 8-bit "Comparison Number" found on the label

of your EMPI Card carton.

Installation Instructions

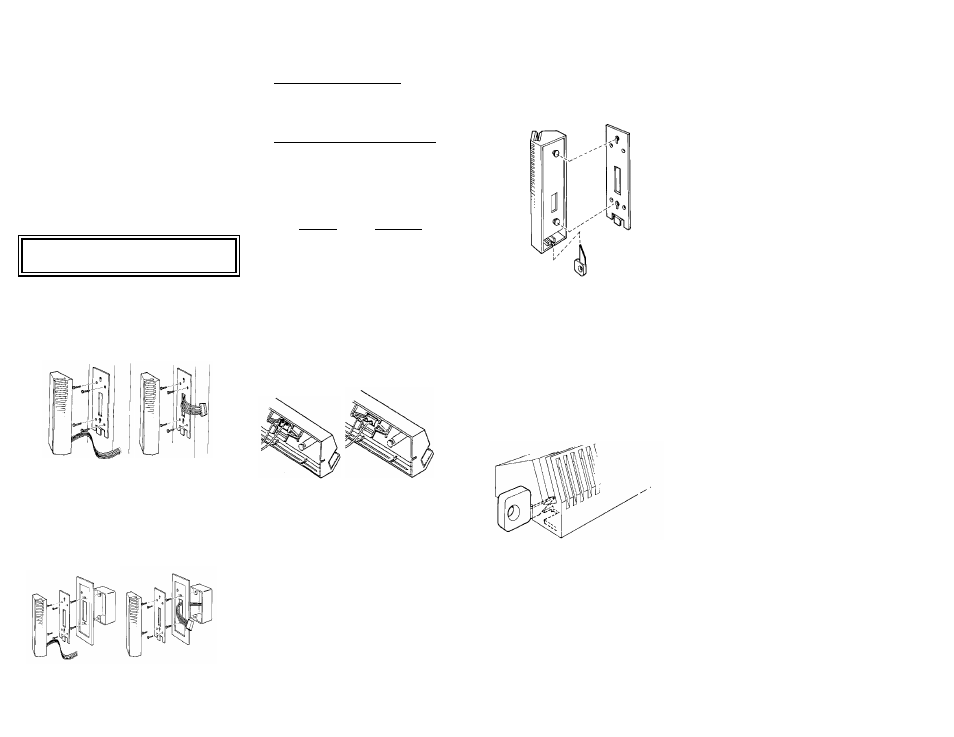

1. Mount the adapter plate, or the reader base plate to a

suitable flat surface or handy box considering both height

from the floor and the reader card slot angle for user

convenience.

2.

The adapter plate is generally used in wall mounting but

can be omitted if space is limited. See FIG 2.

Pigtail

Connectorized

Figure

2.

3.

When required, use either the adapter plate or base plate

as a template to establish drill hole locations. If using the

#6-32 self-tapping sheet metal screws provided, use a

3/32" diameter drill. If desired, suitable molly fasteners,

etc., (not provided) can be used. Use the center

rectangular hole in the plate as a guide to remove

sufficient material for wire and connector clearance. See

FIG 3.

Pigtail

Connectorized

Figure 3.

4. Pull an appropriate length and gauge of 5 or 6-wire

conductor cable between host and reader (or connector).

#22 AWG up to 200 feet

#18 AWG up to 500 feet

5.

Connectorized - Models 6448 and 6449

Connect the wires of the 5-wire cable connector

assembly to the cable end at the reader location.

Connections can be crimped or made with twist-on

wire nuts. Do not plug the connector into the

reader yet.

Pigtail Cable - Models 6444, 6445, 6446 and 6447

Connect the wires of the 6-conductor cable

assembly to the cable end at the reader location.

Connections can be crimped or made with twist-on

wire nuts.

6.

Connect the other end of the cable to the host controller

being sure to follow the appropriate color code and wire

lead functions.

* - Models 6446/6447: The two BLUE wires

connect to the HEATER BAR, which must be

powered by a 24 VAC or 24 ADC source.

Head Track Adjustment

The reader head track location may be changed in the field by

snapping out the head/gimbal assembly, rotating the assembly

180 degrees, and re-installing the assembly in the reader case.

Track I

Track II

.

Attaching Reader to Base Plate

1.

On Models 6448 and 6449 only, plug the cable connector

assembly into the back of the reader (the plug is designed

to fit only one way). On all other models, the cable should

already be connected.

2.

Align the two protruding retainer pins in the underside of

the reader assembly with the corresponding holes in the

reader base plate. FIG 4.

Figure 4

3. Fully insert these pins into base plate holes and gently

slide the reader assembly in the direction of the base plate

latch (approximately 1/4" or 6.35 mm) until the latch locks

against the latch release stop.

Releasing Reader from Base Plate

1.

To release the reader assembly from the reader base

plate, insert the latch release tool into the reader assembly

release slot, making sure the tip of the tool rides on top of

the latch. When fully inserted, the tip of the tool will

depress the latch sufficiently to clear the release stop.

FIG 5.

Figure 5.

2. While holding the release tool in this position, slide the

reader assembly forward (approximately 1/4" or 6.35 mm)

and lift the reader off its base.

3.

Disconnect (or unplug) the cable connector assembly from

the back of the reader.

Options

Reader options are selected by a 16 position rotary switch

located at the top of the reader circuit board.

NOTE: For Model 644-S, Custom proms have a custom ABA

format and may not follow the table below.

The options control the card type accepted (ABA or EMPI) as

well as the output format.

Switch

Function

Position

0

Northern card to 32 bit Wiegand

(FC=16 bits. ID=16 bits)

1

ABA card, all bits raw data - clock and data

2

Reserved for Custom Prom

3

ABA card all bits raw data, except leading 0’s

stripped - clock & data

4

ABA card all ABA digits, plus 10 leading & 10

trailing 0’s - clock & data output

5

ABA card all ABA digits, plus 10 leading & 10

trailing 0’s - Wiegand output

6

ABA card convert last 4 ABA digits in first field

to binary and output as 26 bit Wiegand

7

ABA card convert last 7 ABA digits in first field

to binary and output as 26 bit Wiegand

8

EMPI card to 26 bit Wiegand

9

EMPI card to 34 bit Wiegand

A

ABA card, convert last 9 ABA digits in first

field to binary and output as 34 bit Wiegand

B

Basic MS raw output - all bits Wiegand in

order received

C

ABA to 26 bit Wiegand (FC=8 bits, ID=16 bits)

D

ABA to 34 bit Wiegand(FC=16 bits ID=16 bits)

E

ABA to 34 bit Wiegand (Mercury compatible)

(FC=12 bits, ID=20 bits)

F

ABA to 26 bit Wiegand (Mercury compatible)

(FC=8 bits, ID=16 bits)

FUNCTION

WIRE COLOR

+5

VDC

RED

COMMON

BLACK

Data "1" Output

WHITE

Data "0" Output

GREEN

LED control line A

BROWN

LED control line B (opt)

YELLOW

HEATER

BAR*

BLUE*

CAUTION

Before touching any internal reader parts, touch a

grounded surface to discharge static electricity from your body.

Self Test

On power-up, the reader does a self test sequence. Observe

that the reader LED flashes green four times.

If the reader does not complete self test or continues with

short double flashes, verify wire connections and voltage.

If the reader completes the self-test by flashing the LED but will

not read cards the following steps apply:

1.

Check that the voltage at the red and black

wires is between 3.2 and 5.5 volts DC.

2.

Read card for the proper format as selected.

The LED should wink dark momentarily.

3.

Try another card.

Head wires

away from

face of reader

Head wires

toward

face of reader

4.

See Diagnostic Test section.

Diagnostic Test

1. The Model 644 Pass-Through Card Reader is factory

calibrated and not field serviceable.

2.

Direct substitution with a known good reader is the best

way to isolate the problem.

3.

Measure the voltage drop at the reader between the RED

(Positive) and the BLACK (Common) wire. It should

measure between 3.2 and 5.5 VDC. Low voltage is a

common source of problems.

4.

Verify that the card used to test is a known good card, and

is authorized in host memory. Verify the reader options

are set correctly for that particular host, and the proper site

code has been recorded in host memory.

5. Verify the wiring, continuity, and connections between

reader and host. If possible, switch the reader input wiring

at the host to another known good input terminal and

retest.

6.

If the problem still can not be resolved, contact your HID

Authorized dealer for assistance.