Installing the tubing, Completing the installation, Re-installing your power-supply – Swiftech H20 220 ULTIMA XT PLUS User Manual

Page 13

Copyright Swiftech 2009

– All rights reserved – Last revision date: 10-29-08- Information subject to change without notice – URL

Rouchon Industries, Inc., dba Swiftech

– 151 West Victoria Street, Long Beach, CA 90803 – Tel. 310-763-0336 – Fax 310-763-7095 - E Mail: [email protected]

13 of 15

8.

I

NSTALLING THE TUBING

Preamble:

Your kit comes with 7/16” ID (5/8” OD) tubing. This type of tubing was

specifically selected following suggestions made by our enthusiast users

because it offers very low flow restriction, similar to that of true ½” ID tubing,

without the bulk of true ½” (which is ¾” OD and therefore hard to work with).

This tubing will fit easily onto standard ½” barbs EXCEPT for the MCP655-B

pump. In effect, the design of the hose barbs on this pump makes it quite

difficult to install this slightly smaller tubing. Two things can be done to ease

this process:

Rub the pump barbs with liquid soap to make them slippery

Soften-up the extremity of the tubes by dipping them in a glass of

boiling water for about 20 to 30 seconds (boil some water in a

microwave oven, then dip the extremity of the tube).

Then work the tube around the pump hose barbs by pushing it firmly. Be

patient, it is not easy but it does work.

Smartcoils and tubing installation

Now that your radiator, water-block, pump and reservoir are in place, it is

time to cut segments of tubing and connect the devices together.

Your kit comes with a 40” length of Smartcoils

which, when extended is a

sufficient length to cover 6 feet of tubing. Use of these coils is recommended

whenever there is a sharp bending radius in order to prevent kinking and

flattening of the tube over time.

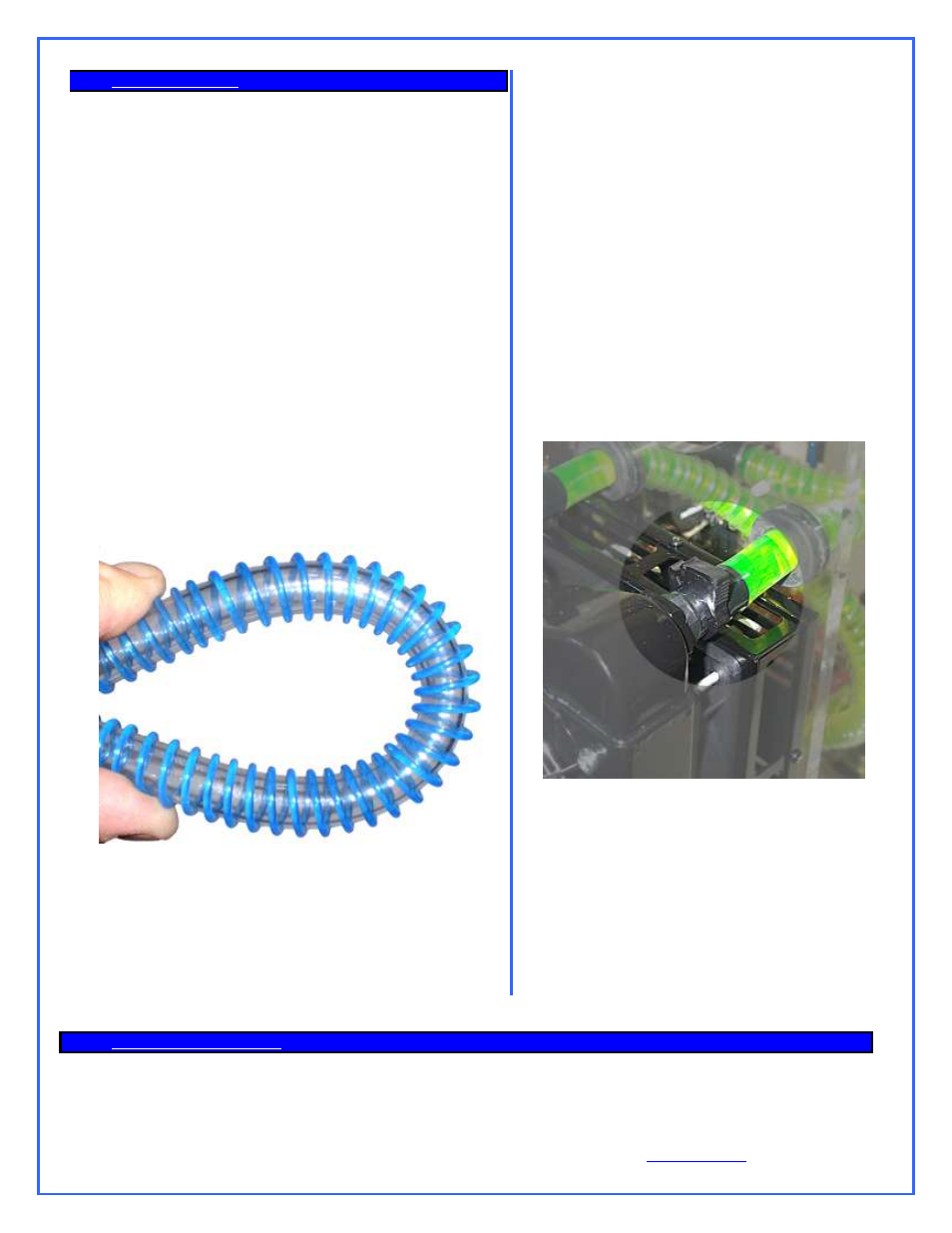

Example of wrapping for a tight bend. (Shown with the blue version for

picture clarity

– The kit actually comes with clear coils).

Wrap the Smartcoils

around the tubing

Gather the Smartcoils

towards the center of the tubing, and then

pull on the ends of the tubing. This will allow the coils to expand to

their natural pitch.

Another technique to evenly spread the coils along the tubing

consists in pushing one of the extremities of the coil clockwise.

This will loosen the coils from around the tube, and allow you to

spread them easily.

Tight radii sections require that coils be close to each other (1/8”

spacing coil to coil). In straight sections, coils can be spaced up to

¼” or more, coil-to-coil.

Then, with one end of a tube connected to a startup

component such as the water-block for example, roughly

estimate the length that you will need to the next component,

and cut the tube and coil squarely with a pair of scissors.

Work your way through the entire circuit in the same fashion,

until you are satisfied with the tube routing.

Secure all the connections of tube to hose barbs with the

provided hose-clamps:

9.

C

OMPLETING THE INSTALLATION

Re-installing your power-supply