Dake Model LE10A User Manual

Page 23

12/10/07 Model LE10A Text

23

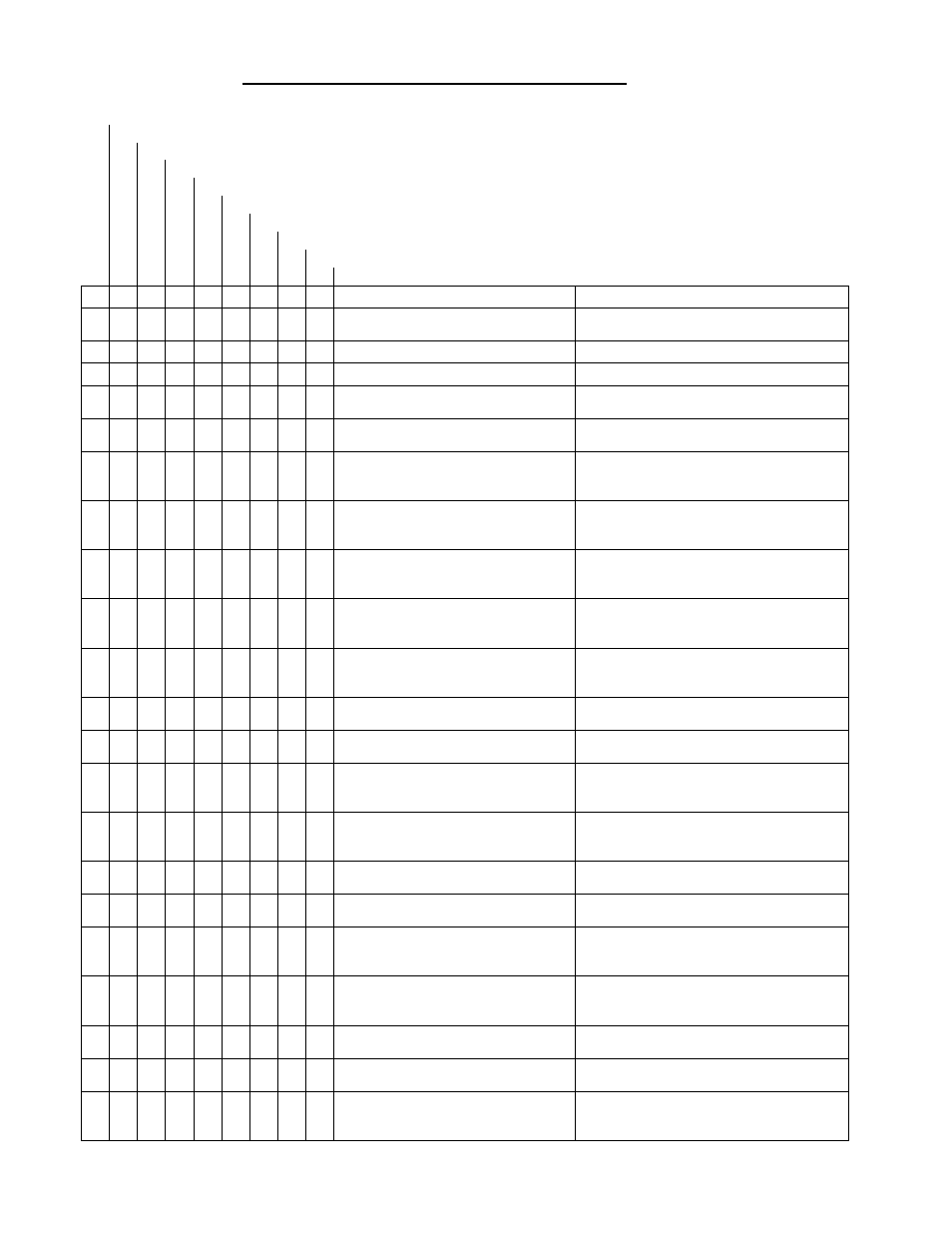

SECTION 8 – TROUBLE SHOOTING CHART 8.1

Machine has power but will not start cut in Semi-Auto mode

Vibration during cutting or excessive noise

Yellow warning light flashes

Material will not feed

Blade cuts crooked or unsure

Hydraulic pump runs when head button pushed but machine will not run

Will not cut in automatic mode

Will not cut to length set on digital readout

Blade Stalls in cut

Use of blade with incorrect pitch.

Call blade supplier.

Failure to break in blade.

Perform break-in (first 12 cuts 1/3 slower

than normal cut rate).

Excessive blade speed.

Reduce speed.

Insufficient blade speed.

Increase blade speed.

Excessive chip load (blade loads up

with chips, too fine).

Reduce load cut slower or coarser blade,

adjust chip brush for cleaning blade.

Wire chip brush worn/improperly

adjusted.

Readjust or replace (just touch blade).

Blade improperly held by insert.

Carbide pads too loose.

Tighten the 2 knurled knobs on guide

arms as tight as possible to reduce pad

clearance, or replace.

Roller table in true alignment with

feeder unit.

Not set straight to machine feed system.

Sits too high or low to the feed roller.

Adjust

Belt slipping stalling blade.

Belt is loose on pulley. Loosen motor

lock handle, push down on motor and

tighten. Replace belt is worn.

Guide arms set too far apart.

Move guide arms closer together. Use

indicator marks on guide arm rail for

proper spacing.

Limit switches on doors and pulley

(open).

Check all doors are closed. Check limit

adjustment, make sure cotter pin is not

interfering with limit activation.

Fuse blown in machine or wall

service.

Check and replace fuses as needed.

Insufficient blade tension.

Tighten blade a half to a full turn beyond

when tensioner lock ring clicks.

Out of stock or end of program E-

stop pushed in.

Press reset button on counter. Make

sure you have stock. Reset number of

pieces in counter check E-stop.

Blade too narrow/too wide (out of

capacity) too long.

Use only blade within cap. .035-.045

thickness. Use blade or correct length &

width.

Coolant mixed incorrect, or no

coolant used.

Mix coolant to manufactures specs. (10-

1) Increase coolant flow.

Front vise not closed.

Jog the vise selector switch and bump

vise close button. This will close vises.

Zero parts entered in piece counter

or zero strokes.

Reset # in piece counter. Must have at

least 1 stroke entered. Out of stock limit

tripped. Feed limit failure.

Not in automatic mode. Reset

piece counter bottom button.

Reset piece counter. Check that

machine is in automatic cycle. Vises are

closed.

Part moved during cut.

Check clamping of part. Use bundle

cutting option for multiple piece cutting.

Movement detector on idle wheel

out of adjustment.

Adjust red LED illuminates as wheel

passes by it.

Length set up wheel backed up

during set up.

Set to length without going beyond

length, and backing up. Backlash is

screw will cause