Dake Model LE10A User Manual

Page 22

12/10/07 Model LE10A Text

22

6.2 Lubrication

Description

Lubricant

Hydraulic Oil

DTE 24 Hydraulic oil

Gearbox Oil

80/90 Synthetic gear lube

Drive wheel

Shell Alvania EP Grease 2 or Mobilplex 48

Idle Wheel

Shell Alvania EP Grease 2 or Mobilplex 48

Blade Tension Device

Shell Alvania EP Grease 2 or Mobilplex 48

Worm Shaft

Shell Alvania EP Grease 2 or Mobilplex 48

Cutting Fluid

Water based coolant

Section 7 – MAINTENANCE

7.1 Periodic Maintenance

After use for the day, clean out saw chips that have accumulated in the machine. To do

this, set the cutting fluid pumps switch at “|”and wash saw chips away with the discharging

cutting fluid.

Before beginning operation for the day, perform the following maintenance operations:

1. Check the hydraulic oil level, adding oil if necessary.

2. Check the cutting fluid level, adding fluid as

necessary. If the fluid appears contaminated or

deteriorated, drain and replace it.

3. Check the saw blade to ensure that it is properly

positioned on both the drive, idle wheels and in the left

and right inserts.

4. Check the wire brush for proper contact with the saw

blade. If it is worn, replace.

5. Check the urethane rope (used on the idle wheel) for

wear. If they are broken, replace.

6. Lubricate the following points:

a. Front vise slide plates

b. Rear vise slide plates

c. Feed cylinder guide shaft.

7.2 Six Month Maintenance

Check the following once every six months:

1. Clean the filters in the cutting fluid tank.

2. Replace the transmission oil (recommended oil: 80/90

synthetic) after the first three months or 600 hours of

operation and every six months or 1200 hours of

operation (whichever occurs first) thereafter.

3. Replace the hydraulic oil.

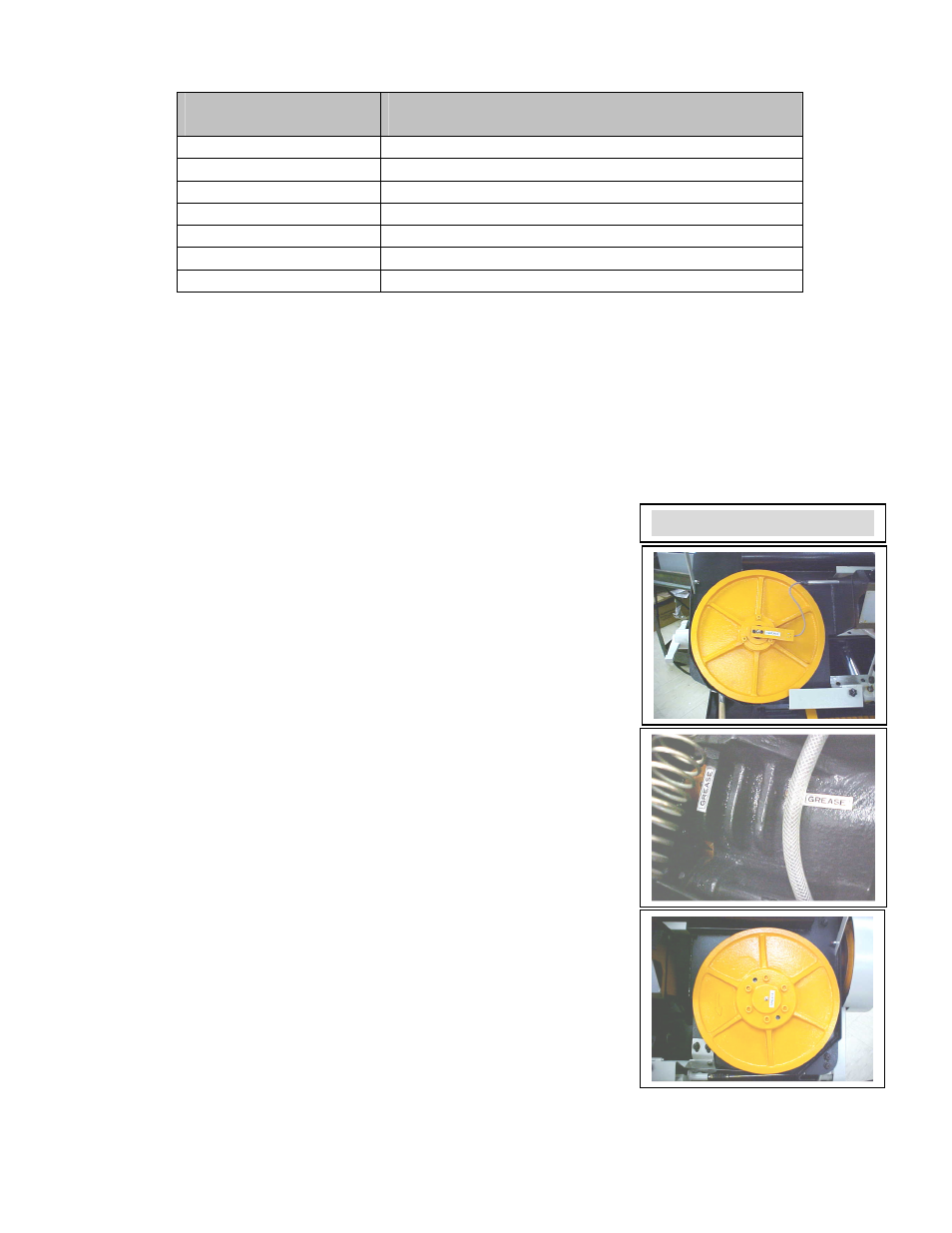

Grease Fittings